A method for optimizing combustion of a chain boiler

A chain boiler, a technology for optimizing combustion, applied in combustion methods, control combustion, combustion equipment, etc., can solve problems such as reducing combustion stability and boiler efficiency, increasing mechanical incomplete combustion loss, and increasing carbon content in fly ash. The equipment layout is convenient, the effect of reducing the heat loss of exhaust smoke and reducing the production of SO3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The method for optimizing the combustion of chain boilers according to the present invention will be further described according to the specific embodiments and the accompanying drawings, but this description does not constitute an improper limitation of the present invention.

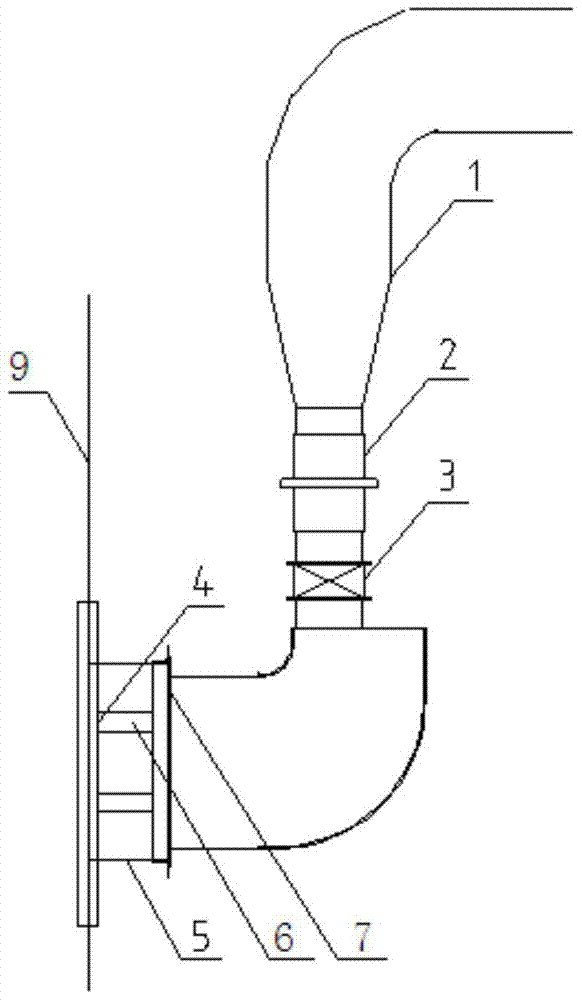

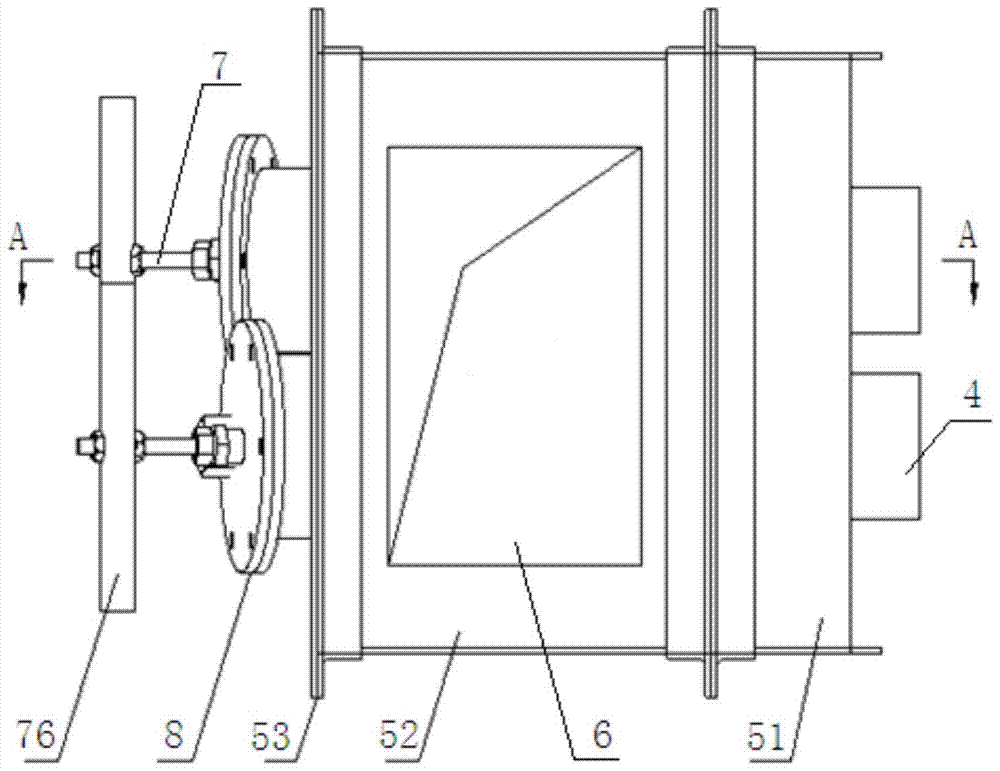

[0054] figure 1 Schematically shows the process flow of the chain boiler optimization combustion method described in the present invention in one embodiment, figure 2 The partial structure of the gas injection box adopted in this embodiment is shown, image 3 The structure of the bellows and the adjusting rod of the gas injection box adopted in this embodiment is illustrated, Figure 4 for image 3 left view of Figure 5 for image 3 A-A sectional view of, Figure 6 The structure of flue gas recycling in this embodiment is illustrated.

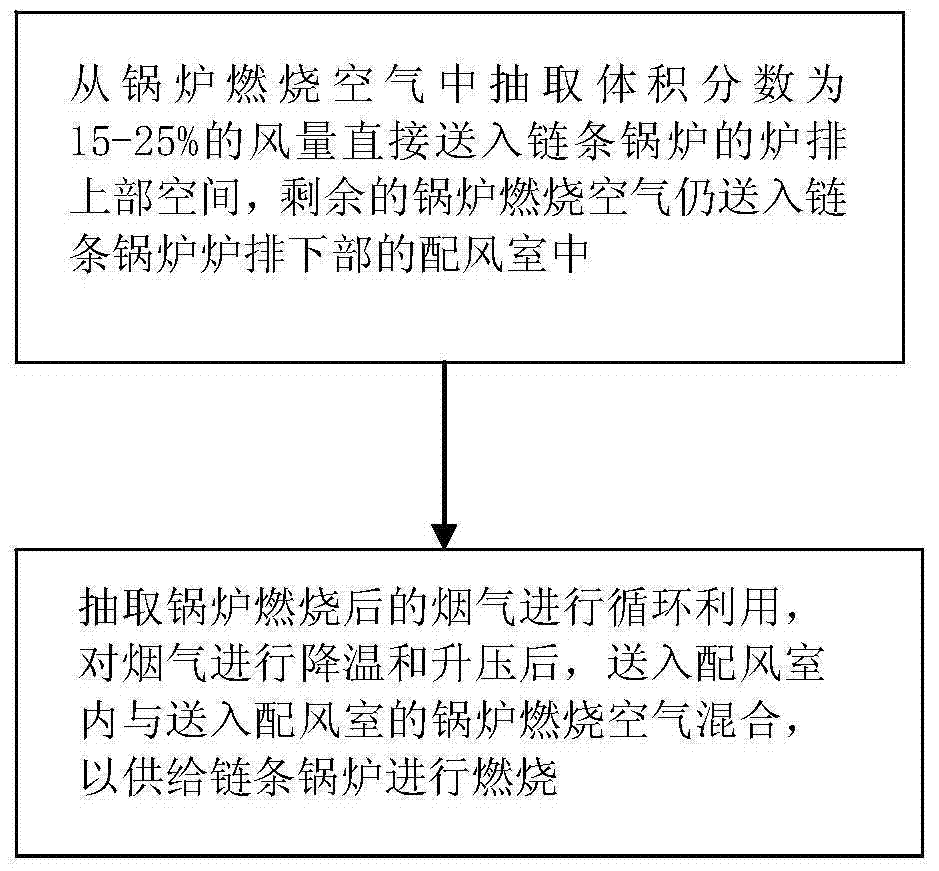

[0055] Such as figure 1 As shown, the chain boiler optimization combustion method of the present embodiment comprises the following steps (the process p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com