Fixed-pressure and stabilized-pressure water replenishment device of heat exchange unit

A technology of heat exchange unit and water replenishment device, which is applied in hot water central heating system, household heating, heating methods, etc., can solve the problems of high price, energy waste, large area occupation, etc., and achieve strong adaptability, flexible and reasonable regulation , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

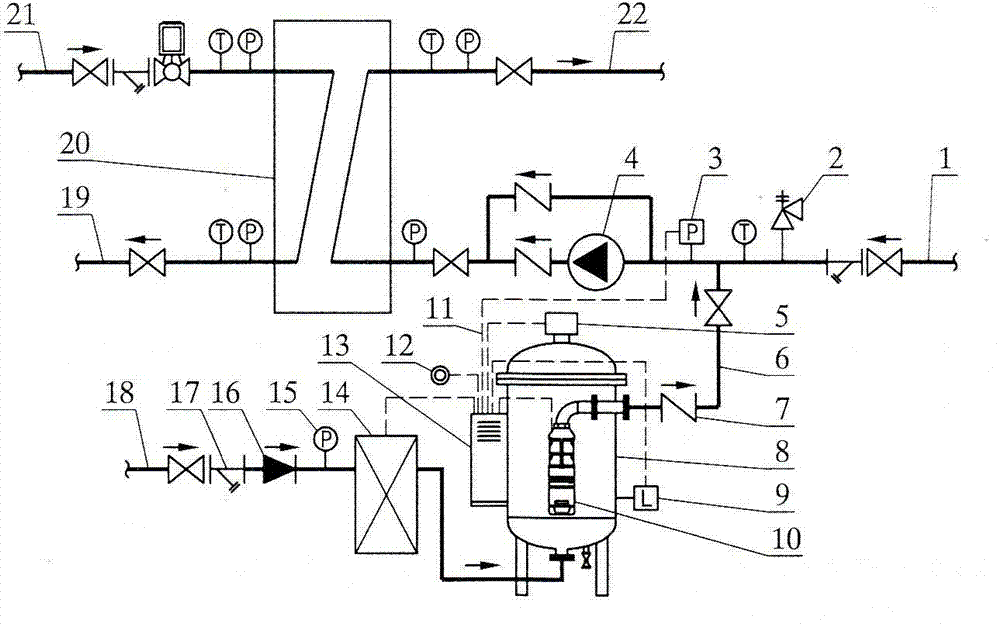

[0010] attached below figure 1 The water replenishment device with constant pressure and constant pressure of the heat exchange unit of the present invention will be described in detail below.

[0011] as attached figure 1 As shown, the heat exchange unit constant pressure and stable pressure water supply device of the present invention is mainly composed of a non-negative pressure booster tank 8, a submersible pump 10, a vacuum suppressor 5, a pressure sensor 3, a filter 17, a backflow preventer 16, and a water processor 14 and the control box 13 are formed, the submersible pump 10 is housed in the non-negative pressure booster tank 8, and the water outlet of the submersible pump 10 is provided with a connecting pipe connected with the water supply pressure pipe 6 outside the non-negative pressure booster tank 8, and the water supply pressure tube 6 is connected with the water supply pressure tube 6 again. The secondary return pipe 1 is connected, the secondary return pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com