Absorption cavity type laser breakdown detection device

A detection device and laser breakdown technology, which is applied in the field of spectral measurement, can solve the problem that the detection sensitivity is difficult to meet higher detection requirements, and achieve the effect of small spectral line broadening effect, preventing interference and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

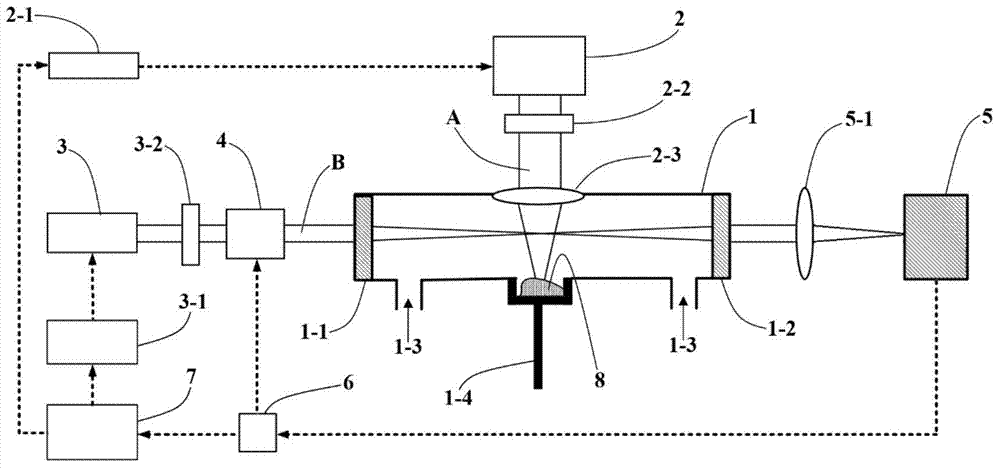

[0029] figure 1 is the basic structure diagram of this embodiment. The excitation light source 2 uses a pulsed Nd:YAG laser that emits a pulsed laser at 1064nm, while the detection light source 3 uses a continuously tunable Ti:Sapphire ring continuous laser with a tunable range of 700-900nm and an output power between 1000-1700W . The efficiency of the first-order diffraction of the AOM 4 is about 85%, and the zero-order diffraction spot is blocked by a small hole diaphragm ( figure 1 Not shown in), the operating frequency is 80MHz. The reflectivity of the two high reflection mirrors of the absorption cavity 1 is 99.995%, the radius of curvature is 1m, the cavity length of the absorption cavity 1 is 1.25m, and the free spectral range of the corresponding ring-down cavity is 120MHz. Absorbing cavity 1 has a ring-down time of 80 μs when there is no sample and is in a vacuum state, the fineness of the cavity is 50000, and the full width at half maximum of the mode in the cavit...

Embodiment 2

[0038] On the basis of embodiment 1, an annular piezoelectric ceramic ( figure 1not shown in ), the output mirror can change the cavity length of the ring-down cavity driven by the piezoelectric ceramic, that is, the cavity length is modulated by the piezoelectric ceramic; the cavity length change under the piezoelectric ceramic modulation is slightly greater than λ / 2 of the detection light, The cavity mode is made to oscillate around the laser frequency.

[0039] When used as a detection light source in the mode of step-scanning, each step is about 0.2s, and the piezoelectric ceramic is set to vibrate at a frequency of 300Hz, so that the detection light is more easily coupled into the absorption cavity, and the detection accuracy is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com