A non-destructive marking device for spark breakdown point of cable insulation

A cable insulation and marking device technology, applied in the direction of marking conductors/cables, etc., can solve the problems of slow marking speed, affecting cable quality, unusable, etc., to achieve easy identification, meet the requirements of marking operations, and overcome the effect of slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

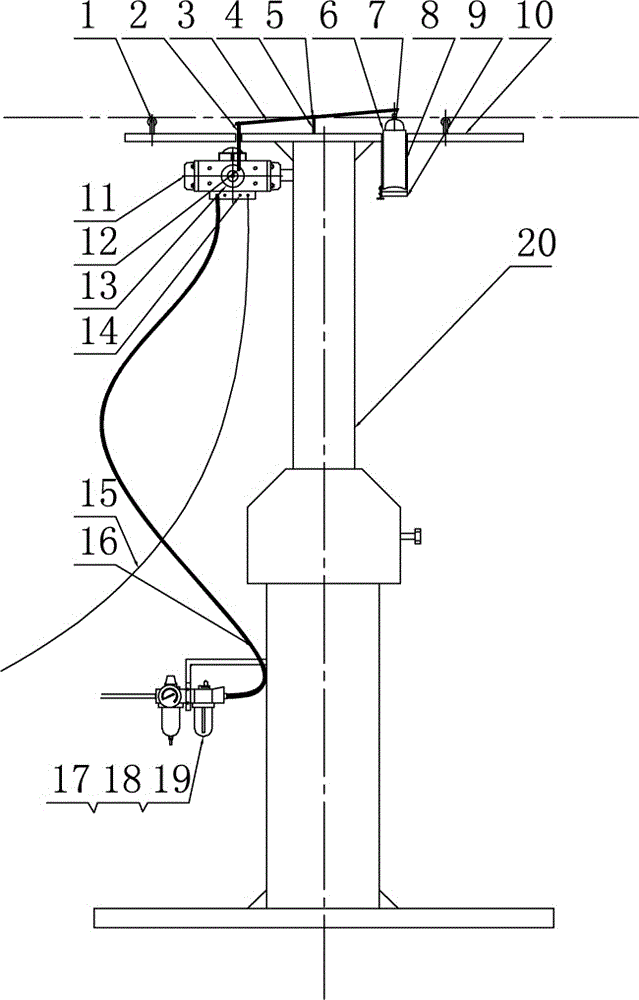

[0016] figure 1 The main structure of the nondestructive marking device for cable insulation spark breakdown point of the present invention is shown. The nondestructive marking device for cable insulation spark breakdown point of the present invention includes a workbench, and the workbench consists of a workbench 10 and a support column 20 The support column is a height-adjustable support column, and a color marking device that can form a color coating on the outer surface of the cable insulation layer is provided on the workbench, and the spark breakdown alarm electrical signal is converted into a driving color marking device. On / off the actuator of the power output, and the transmission mechanism that transmits the output power of the actuator to the control switch of the color marking device. Cable idlers 1 are arranged on the working table on both sides of the color marking device.

[0017] Described color marking device is self-spray paint 6, is provided with the self-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com