Speed sensor-free high-voltage synchronous motor vector control method

A speed sensorless, synchronous motor technology, applied in vector control systems, motor generator control, AC motor control, etc., can solve the problem of being easily affected by the environment, the measurement accuracy of the speed encoder, and the simplicity of the motor speed control system, etc. problem, to achieve the effect of simplifying the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

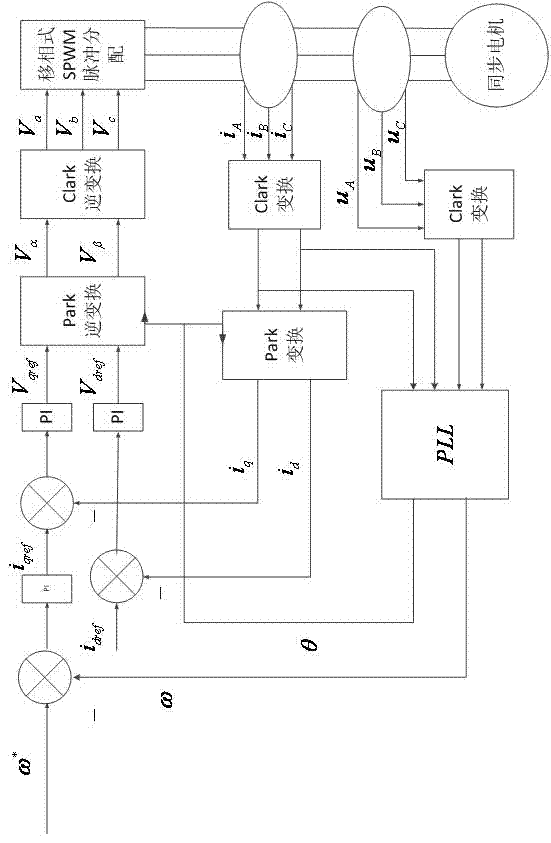

[0028] The invention is a vector control method of a high-voltage synchronous motor without a speed sensor. figure 1 As can be seen from the structure diagram of the high-voltage synchronous motor vector control system without speed sensor shown, the specific implementation steps of the present invention are as follows:

[0029] 1) Real-time sampling to obtain the stator voltage u of the synchronous motor A , u B , u C and stator current i A i B i C ;

[0030] 2) Obtain the rotor angular velocity ω and rotor position electrical angle θ of the synchronous motor through a phase-locked loop;

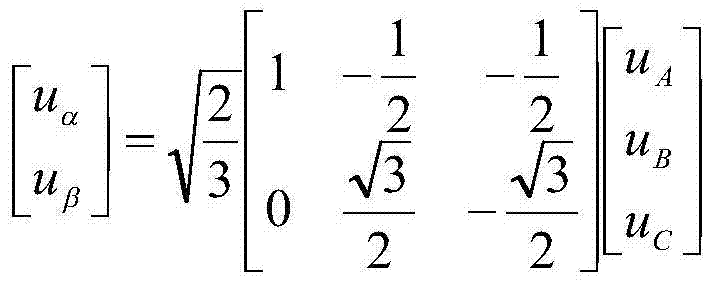

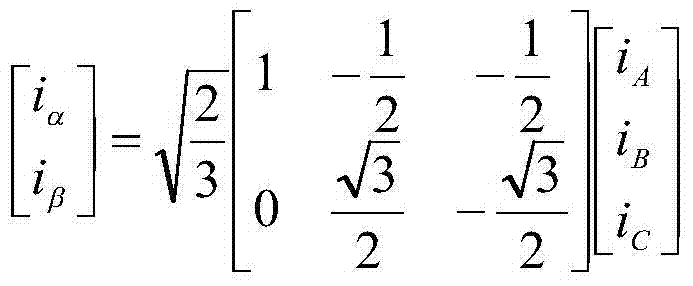

[0031] The stator voltage u obtained in step 1) is transformed by Clark transform A , u B , u C and stator current i A i B i C Transform to the two-phase stationary coordinate system to obtain the stator voltage u on the two-phase stationary coordinate system α , u β and stator current i α i β ,Right now

[0032] u ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com