A personalized β‑ti‑15mo alloy‑al 2 o 3 Ceramic tibial plateau artificial bone scaffold

A tibial plateau, -ti-15mo technology, applied in the field of medical devices, can solve problems such as research gaps in the application of bone defects around joints, and achieve the effects of low surface friction coefficient, high wear resistance, and long-term wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

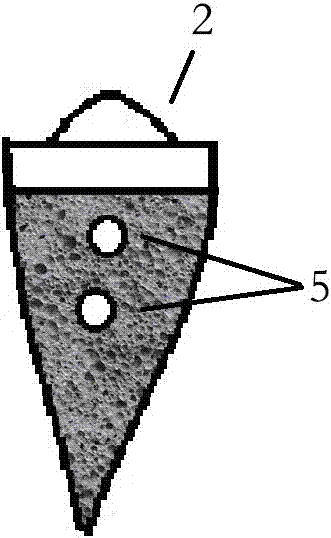

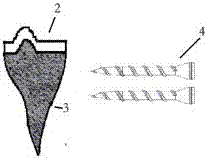

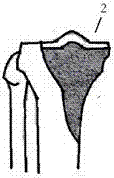

[0014] Embodiment 1: Carry out thin-slice CT scanning to tibial plateau fracture area, obtain the thin-slice CT image that contains fracture defect part, apply MIMCS software to design CAD three-dimensional model, input final design parameter into 3D printer, 15wt%Mo, 1wt%TiO 2 and 84wt% Ti powder and Al 2 o 3 The powders are respectively added to the powder tank of the selective laser sintering system, using selective laser sintering technology, heated to 1200°C under the protection of inert gas, and the heating rate is 5°C / min~10°C / min, and the integrated porous β- Ti-15Mo Alloy Trabecular Bone 3 and Al 2 o 3 The main part of the ceramic articular surface 2 is annealed after being kept warm for 2 hours and gradually cooled with the furnace at a cooling rate of 5°C / min to 10°C / min. The printed 3 porous β-Ti-15Mo alloy trabecular bone and Al 2 o 3 The ceramic articular surface 2 is implanted in the tibial plateau fracture area, and fixed in the fracture area with two scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com