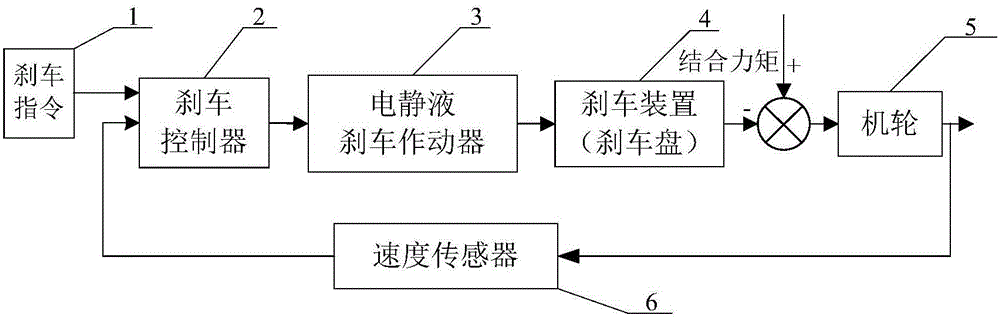

Aircraft electro hydrostatic brake actuator

A technology of electrostatic fluid and actuator, which is applied in the direction of aircraft brake arrangements, brakes, brake regulators, etc., can solve the problems of inability to maintain the brake pressure of the take-off line for a long time, large volume and weight, and low system efficiency, and achieve The effect of high frequency response, small volume and weight, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

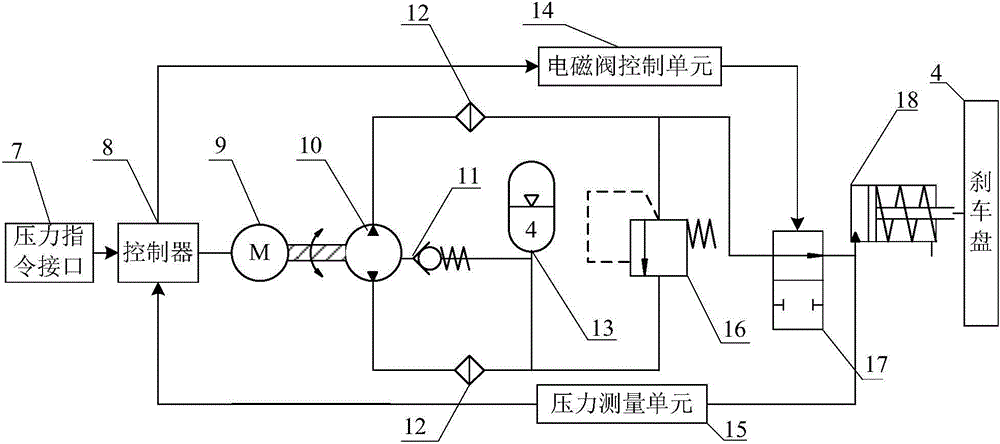

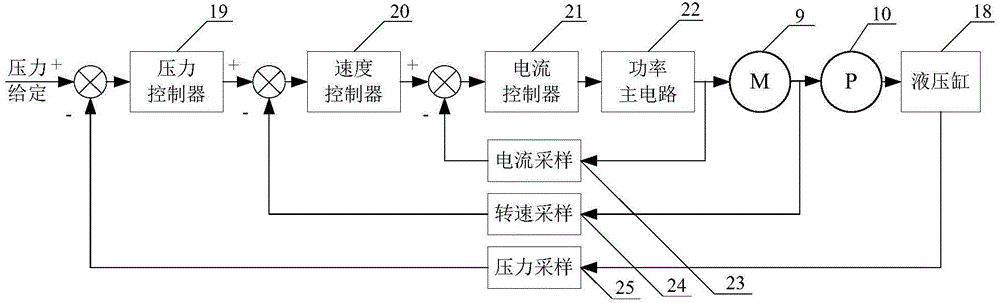

[0023] The technical solution adopted by the present invention to solve the technical problem is: the system includes a pressure command interface, a controller, a brushless DC motor, a fixed displacement bidirectional plunger pump, a check valve, an oil filter, a pressurized oil tank, and a solenoid valve control unit , Pressure measuring unit, safety valve, 2-position 2-way solenoid valve, hydraulic cylinder, brake device (brake disc). The brushless DC motor is coaxially connected with the fixed-displacement bidirectional plunger pump to drive the fixed-displacement bidirectional plunger pump to run efficiently. The pressurized oil tank provides a certain initial pressure to the inlet of the fixed-displacement two-way plunger pump, prevents the occurrence of cavitation in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com