Facultative device applied to sewage treatment

A technology for sewage treatment and sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the impact on the survival of fish and other aquatic animals, ecological environment impact, production cost Advanced problems to achieve the effect of ensuring pressure, improving efficiency and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below through specific examples.

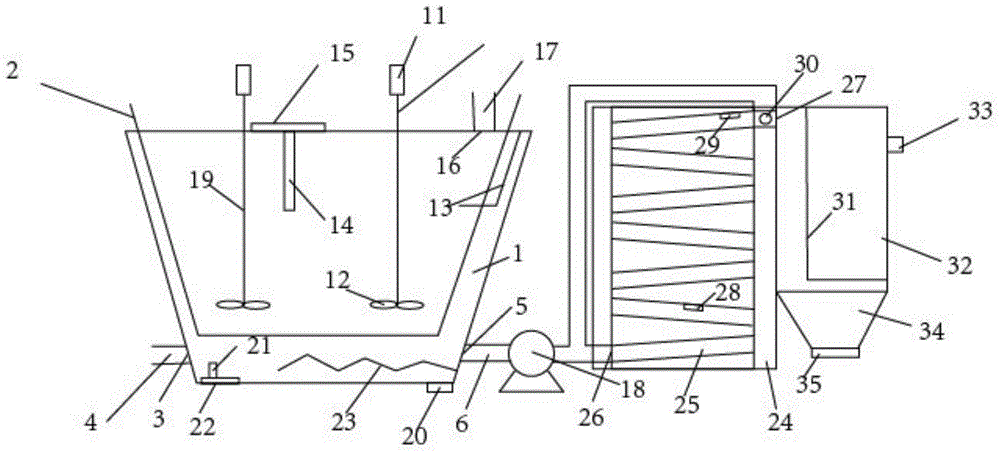

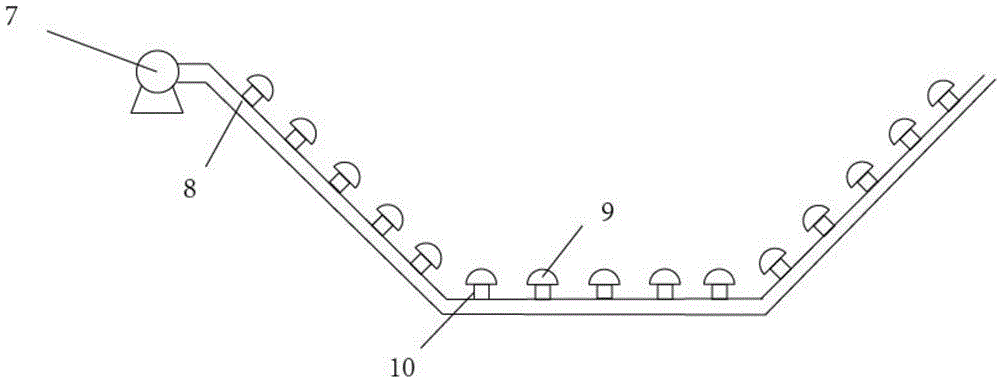

[0017] Such as figure 1 and figure 2 As shown, among them, 1 is the main body of the regulating tank, 2 is the aeration device, 3 is the sewage water inlet, 4 is the sewage water inlet pipeline, 5 is the sewage water outlet, 6 is the sewage drainage pipeline, 7 is the aeration intake pump, 8 is the aeration inlet pipeline, 9 is the aeration head, 10 is the aeration connecting pipe, 11 is the stirring motor, 12 is the stirring head, 13 is the sludge recovery tank, 14 is the sludge collection scraper, 15 is the scraper Sliding guide rail, 16 is the air outlet, 17 is the exhaust pipe, 18 is the sewage pump, 19 is the stirring lifting rod, 20 is the bottom sludge export tank, 21 is the export scraper, 22 is the export scraper slide rail, 23 is Bottom sludge is exported to the bottom plate, 24 is the acid regulating reflux tower, 25 is the regulating reflux pipe, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com