A method suitable for Daqu Qingxiang Baijiu to control acidity and improve efficiency in hot season

A technology for Daqu and liquor, applied in the field of acid control and efficiency improvement of Daqu Qingxiang liquor in hot season, can solve the problems of affecting the yield of wine, easy to rancidity, etc., and achieve the effects of clear seed quantity, prevention of rancidity in hot season, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

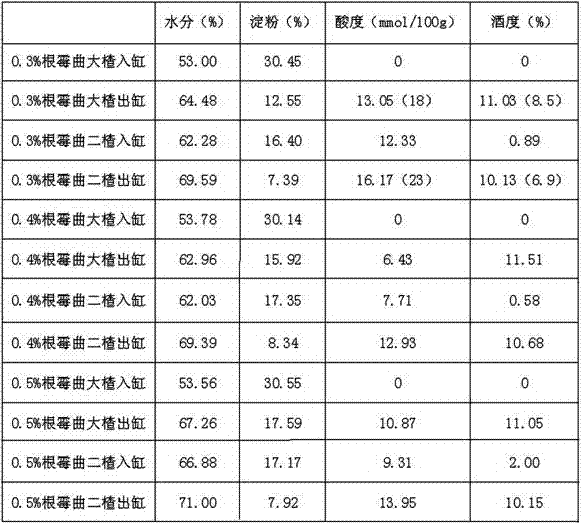

Embodiment 1

[0012] Example 1: A method suitable for hot season acid control and efficiency improvement of Daqu Qingxiang Baijiu, using the brewing process of Fenjiu Daqu Qingxiang Baijiu, using sorghum as raw material, reducing the amount of Fenjiu Daqu, and fermenting with Rhizopus koji, cerevisiae and ester-producing yeast winemaking.

[0013] The amount of said koji material is: the amount of Fenjiu Daqu is 2.5% of the raw material, i.e. the dry weight of sorghum, the amount of rhizopus koji is 5‰ of the weight of the dry material of sorghum, and the amount of Saccharomyces cerevisiae is 1‰ of the weight of the dry material of sorghum, The amount of ester-producing yeast used is 1‰ of the weight of the raw material, that is, the weight of sorghum dry matter; fermented in earth vats for 13 days; and the initial fermentation temperature is controlled at 30°C.

[0014] The specific steps are as follows: sorghum removal of impurities, crushing, mixing grits, steaming grits, cold dispersing...

Embodiment 2

[0015] Example 2: A method suitable for hot season acid control and efficiency improvement of Daqu Qingxiang Baijiu, using the brewing process of Fenjiu Daqu Qingxiang Baijiu, using sorghum as raw material, reducing the amount of Fenjiu Daqu, and fermenting with Rhizopus koji, cerevisiae and ester-producing yeast winemaking.

[0016] The amount of the koji material is: the amount of Fenjiu Daqu is 5% of the raw material, that is, the sorghum dry matter, the rhizopus koji amount is 4‰ of the raw material, that is, the sorghum dry matter, and the amount of Saccharomyces cerevisiae is 0.8‰ of the raw material, that is, the sorghum dry matter. The dosage is 0.8‰ of the raw material, that is, the sorghum dry material; the ground tank is fermented for 14 days; the initial fermentation temperature is controlled at 27°C.

[0017] The specific steps are as follows: sorghum removal of impurities, crushing, mixing grits, steaming grits, cold dispersing the next koji, and ground tank ferm...

Embodiment 3

[0018] Example 3: A method suitable for hot season acid control and efficiency improvement of Daqu Qingxiang Baijiu, using the brewing process of Fenjiu Daqu Qingxiang Baijiu, using sorghum as raw material, reducing the amount of Fenjiu Daqu, and fermenting with Rhizopus koji, cerevisiae and ester-producing yeast winemaking.

[0019] The amount of the koji material is: the amount of Fenjiu Daqu is 7.5% of the raw material, i.e. the sorghum dry matter, the rhizopus koji amount is 3‰ of the raw material, that is, the sorghum dry matter, the amount of Saccharomyces cerevisiae is 0.5% of the raw material, that is, the sorghum dry matter, and the ester-producing yeast The dosage is 0.5‰ of the raw material, that is, the sorghum dry material; the earth tank is fermented for 15 days; the initial fermentation temperature is controlled at 25°C.

[0020] The specific steps are as follows: sorghum removal of impurities, crushing, mixing grits, steaming grits, cold dispersing the next koj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com