Recombinant bacteria with improved alpha-phenylpyruvic acid transformation production efficiency

A technology of phenylpyruvate and recombinant bacteria, applied in the field of recombinant bacteria, can solve the problems of low product yield, increased difficulty of separation and purification, toxic and harmful products, etc., achieve high yield, solve cumbersome steps, and increase production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

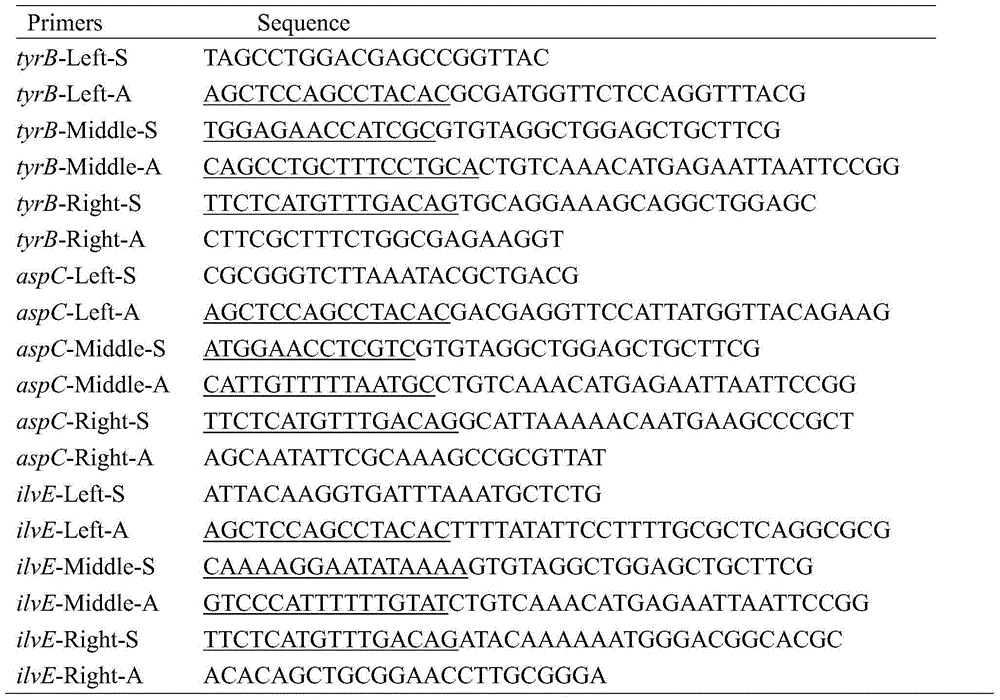

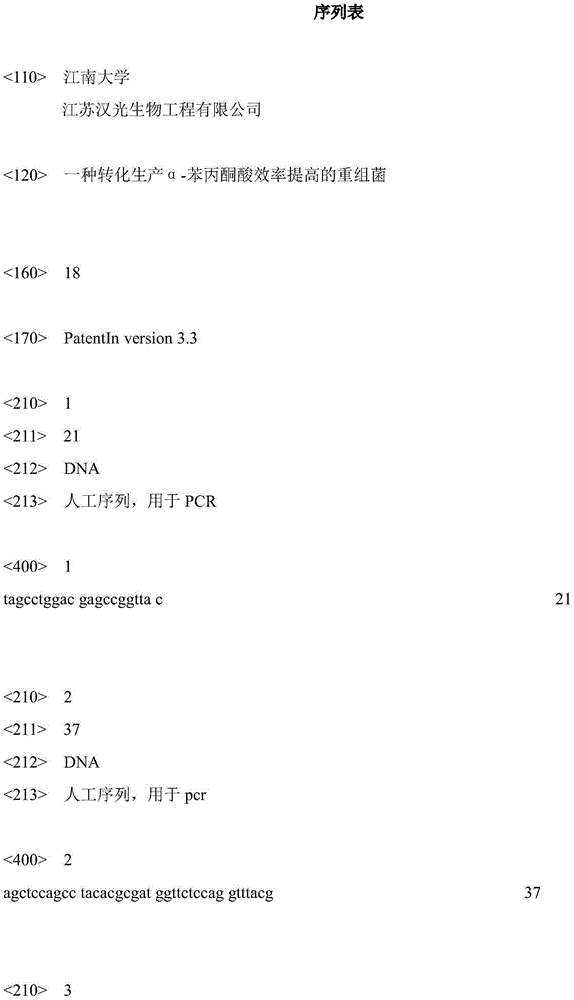

[0021] Example 1 Knockout of aspC, tyrB and ilvE genes

[0022] Previously, we expressed the L-amino acid deaminase gene through E. coli, and obtained a recombinant E. coli strain expressing L-amino acid deaminase. This recombinant E. coli can be used for whole-cell transformation of L-phenylalanine to produce PPA. See The title of the invention is "A method for efficient production of α-phenylpyruvate by whole cell transformation", and the patent application number is 201310392427.6. The recombinant Escherichia coli genomic DNA is used as a template, and aspC-Left-S and aspC-Left-A are used , tyrB-Left-S and tyrB-Left-A, ilvE-Left-S and ilvE-Left-A as primers, PCR amplified about 1000bp upstream of aspC, tyrB and ilvE genes, and aspC-Right-S and aspC-Right -A, tyrB-Right-S and tyrB-Right-A, ilvE-Right-S and ilvE-Right-A were used as primers, and about 1000 bp downstream of aspC, tyrB and ilvE genes were amplified by PCR.

[0023] Using pKD13 as template, using aspC-Middle-S ...

Embodiment 2

[0024] Example 2 Preparation of Whole Cell Catalyst and Whole Cell Transformation Process

[0025] The recombinant Escherichia coli in Example 1 after aspC, tyrB and ilvE knockouts were inoculated into seed medium (containing ampicillin 10 mg / L), and cultivated overnight at 37° C. and 200 rpm. Fermentation was carried out in a 3L NBS fermenter, 1% inoculum was added to 1.8L fermentation medium, the stirring speed, ventilation and temperature were 400rpm, 1.0vvm and 28°C, respectively, when OD 600 When 0.6 was reached, 0.4 mM IPTG was added to induce the expression of L-amino acid deaminase. After 5 hours of induction, centrifuge at 8,000 rpm for 10 minutes at low temperature, collect the bacterial cells, and wash the bacterial cells twice with 20 mM Tris-HCl (pH 8.0) buffer. The whole cell transformation system is: L-phenylalanine 4g / L, whole cell catalyst 1.2g / L, the reaction is carried out in 20mM Tris-HCl (pH 8.0), 37°C, 200rpm transformation for 24h.

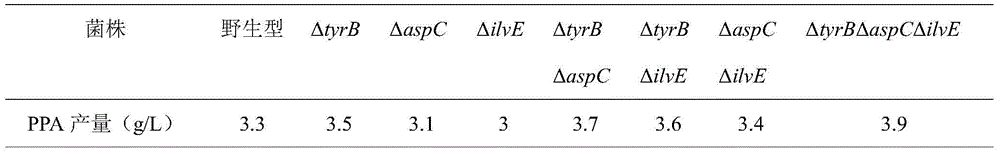

[0026] See Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com