Directional drainage two-cloth one-film anti-seepage drainage structure

A technology of anti-seepage drainage and membrane surface, which is applied in the direction of infrastructure engineering, road, soil protection, etc., can solve the problem of increasing the flow distance and time of water on the membrane, unfavorable roadbed maintenance, and prolonging the residence time of water in the roadbed, etc. problem, to achieve obvious drainage effect, speed up the flow rate, and reduce the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

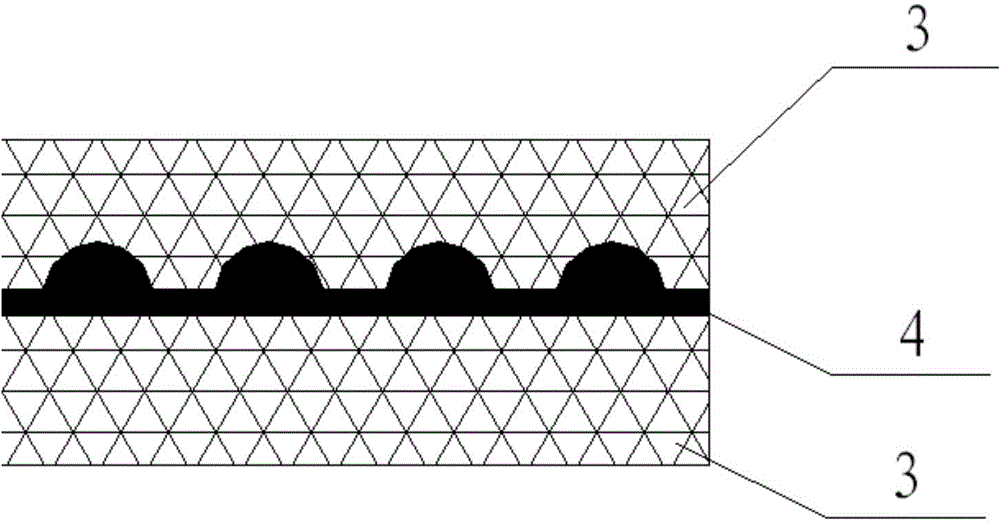

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings. like figure 2 As shown, the roadbed directional drainage two-cloth-one-film anti-seepage structure of the present invention includes two layers of filament non-woven fabric 3 sandwiching a layer of ribbed plastic film 4, and the ribbed plastic film 4 has parallel raised ribs. The plastic film 4 has a thickness of 0.3 mm to 2.0 mm, and is arranged on one side or both sides of the plastic film 4 . The ribs are made of plastic film 3 and are molded together with the plastic film 3 at one time. The cross-sectional shape of the rib is trapezoidal or semicircular. The distance between the ribs is 20-100mm, and the height is 0.5-2.0mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com