Cylindrical structure gradual-change fin phase change heat accumulator

A gradient fin, phase change heat storage technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of high thermal stress, low thermal conductivity, and low utilization rate of square heat storage containers. problems, to achieve the effect of improving heat storage effect, consistent heat transfer temperature difference, and increasing melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments will be described in detail below in conjunction with the accompanying drawings.

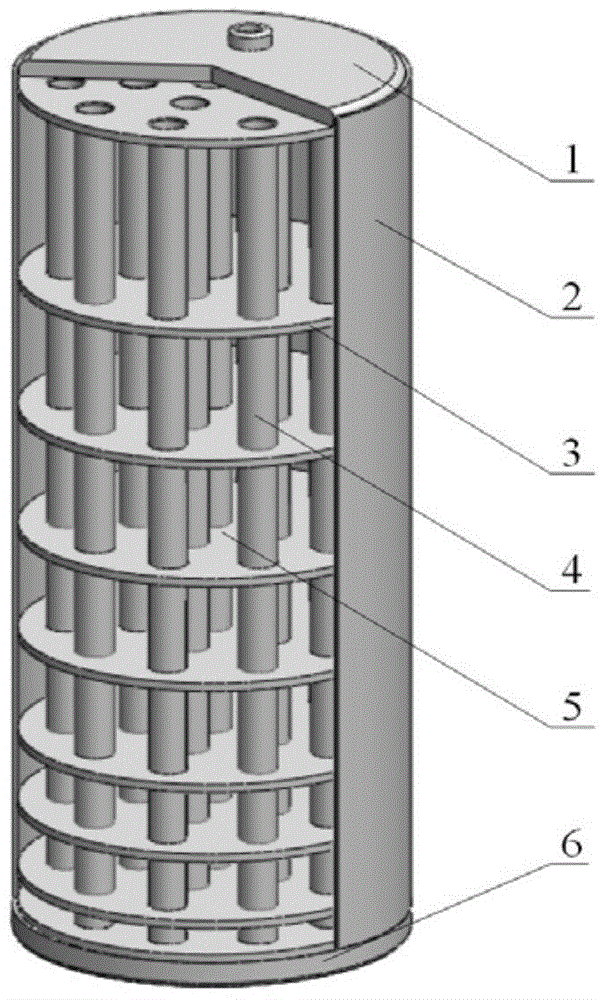

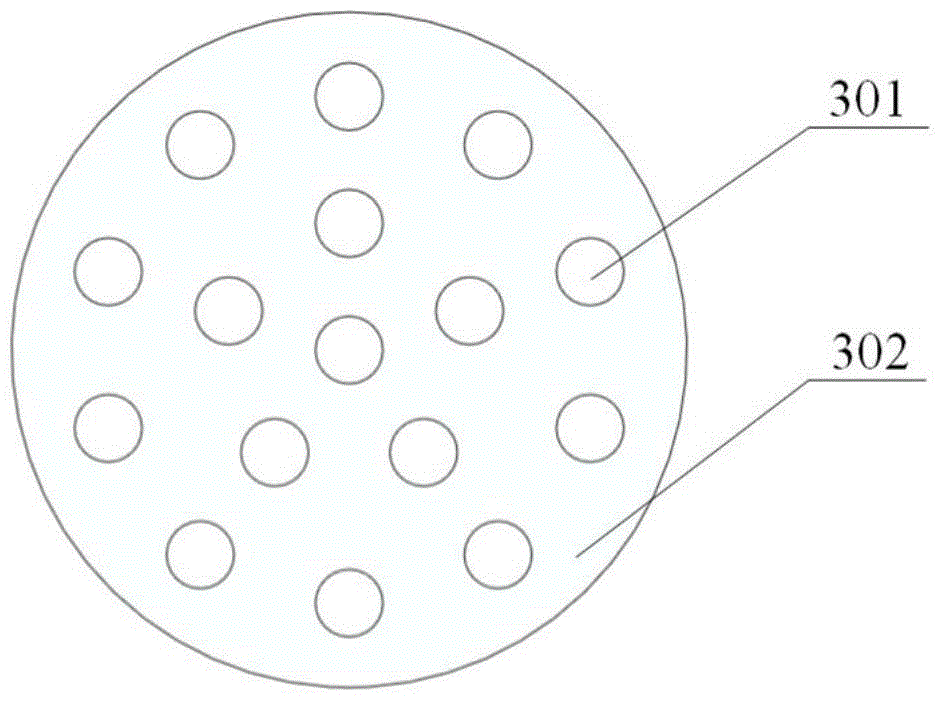

[0017] like figure 1 As shown, the present invention is composed of an upper end surface 1 , a heat storage shell 2 , an annular fin 3 , a heat exchange tube bundle 4 , a phase change material 5 and a bottom surface 6 . The overall structure of the heat accumulator is cylindrical and arranged vertically. The annular fins 3 are arranged horizontally, and the annular fins 3 of each stage are integrated, and the interfaces of the heat exchange tube bundles 4 are equidistantly arranged according to the specific requirements of heat storage. The heat exchange tube bundles 4 are vertically arranged parallel to each other and equally spaced. A heat exchange fluid flows in the heat exchange tube bundle 4 . The phase change material 5 is stored between the annular fins 3 , and the fin spacing of the annular fins 3 decreases continuously along the direction in which the heat tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com