Optical fiber cantilever beam microphone for photoacoustic spectrum detection and manufacturing method

A photoacoustic spectroscopy, cantilever beam technology, applied in color/spectral characteristic measurement, instruments, measuring devices, etc., can solve the problems of not strictly linear displacement response, unfavorable accurate detection of photoacoustic signals, etc., to avoid inaccurate measurement, Increased practicality, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

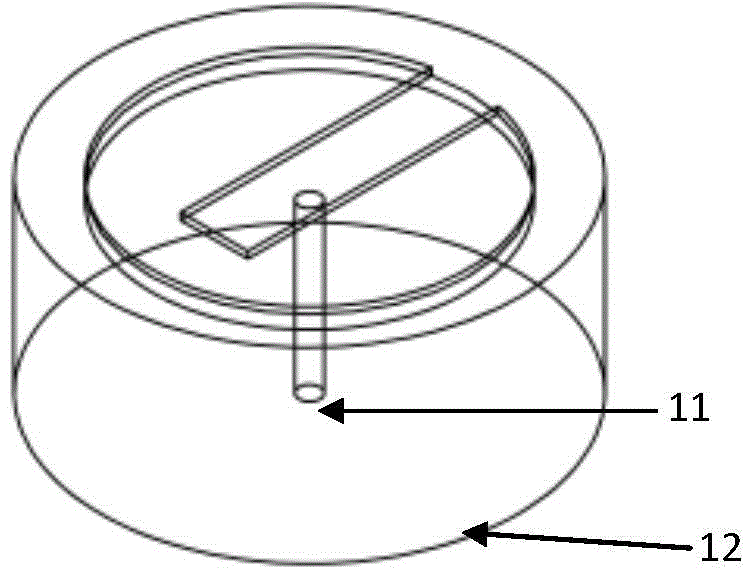

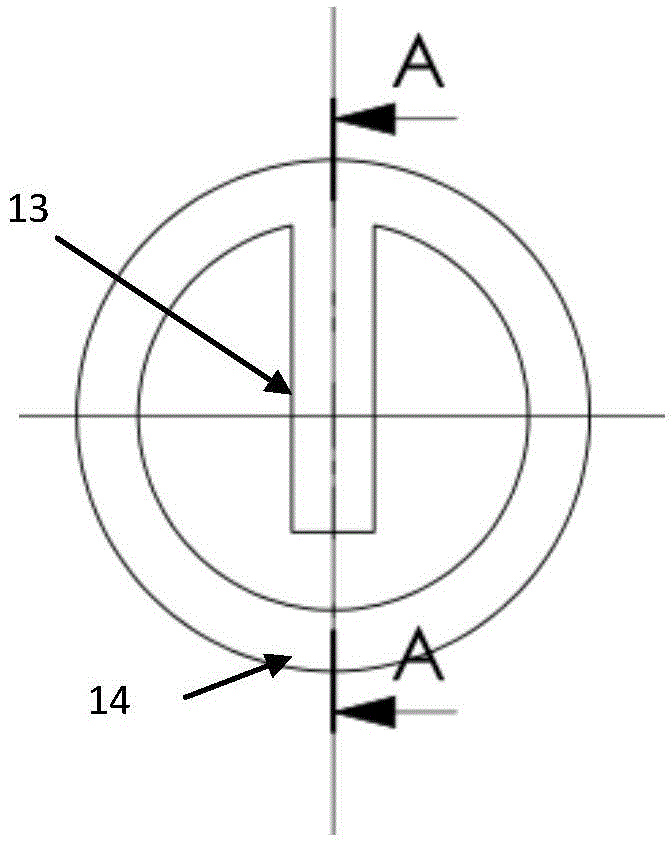

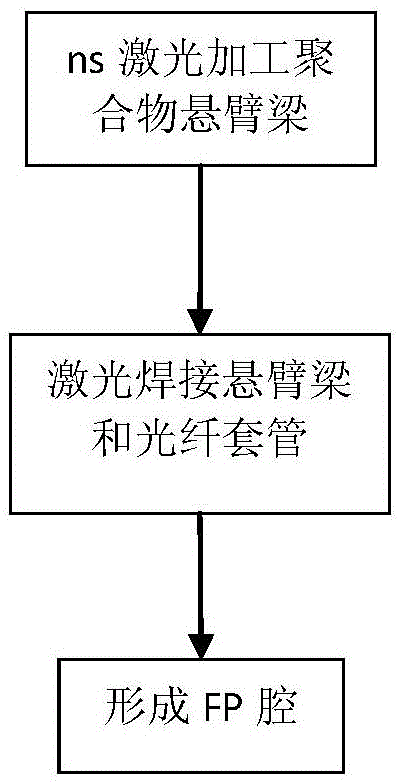

[0033] Such as image 3 As shown, the manufacturing method of the optical fiber cantilever beam microphone for photoacoustic spectrum detection of the present invention is as follows: first, the polymer annular film 14 is fixed on the laser processing table, and the nanosecond pulse laser is processed according to the set program to obtain the polymerized Object cantilever beam 13. The laser repetition frequency used in processing is generally 40kHz, and the average power is less than 1mW. The shape of the polymer cantilever beam can be controlled by software, and it is generally rectangular, so as to facilitate the connection with the fiber optic ceramic sleeve while maintaining high sensitivity. The processed cantilever beam 13 is welded together with the optical fiber ceramic sleeve 12 by laser cladding, and then the single-mode optical fiber 11 is inserted into the optical fiber ceramic sleeve 12 and the surface of the polymer cantilever beam to form an FP interference cavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com