A Method for Simulation and Analysis of Polarization of Photolithography Projection Objective Lens

A technology of simulation analysis and lithography projection, which is used in microlithography exposure equipment, photolithography process exposure devices, etc., to achieve the effects of reduced cost, low cost and convenient simulation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

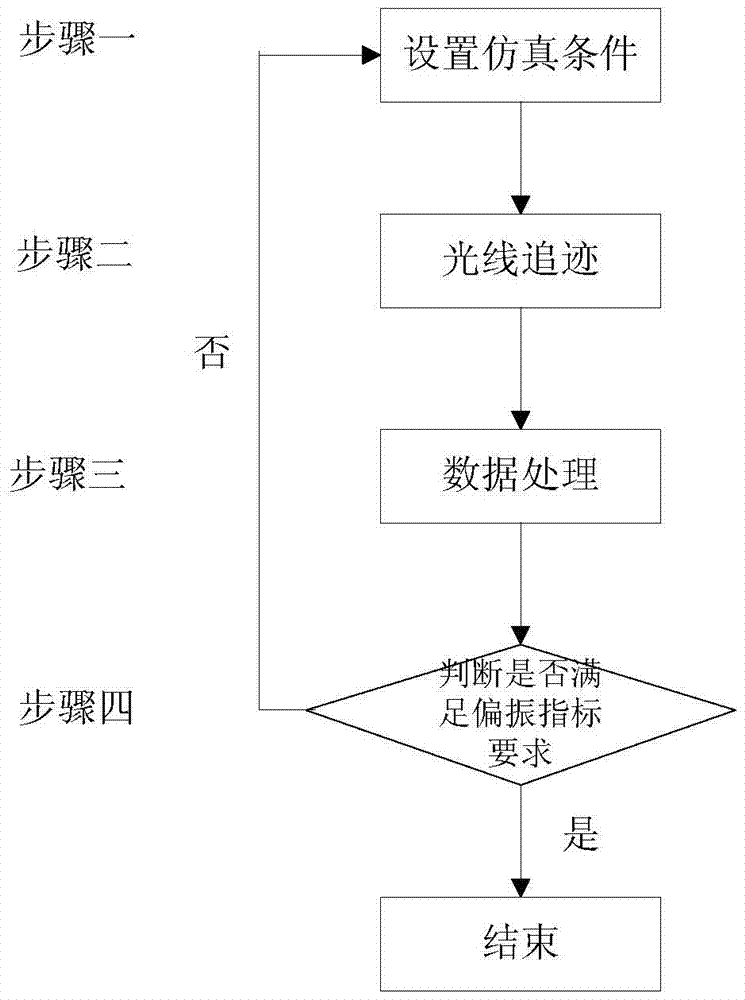

[0058] Step 1: Set the simulation conditions, where the input polarization mode selects linearly polarized light, the input beam polarization degree is 99.7%, the polarization state description method is set to Stokes vector, the loading film system (MgF2 single-layer film), and the material birefringence characteristics Load, select the field of view (0, 0) field of view;

[0059] Step 2: Ray tracing, where the number of traced rays is set to 1 million, and the polarization mode is turned on;

[0060] Step 3: Data processing. Obtain corresponding data through the compiled macro language file, including polarization type, polarization direction, intensity in X and Y directions, and degree of polarization. The specific data are as follows:

[0061] Sides Ix Iy degree of polarization Polarization direction Polarization type Object surface 0.99850 0.00150 0.99700 -90 0 1 0.94707 0.00143 0.99698 -90 0 2 0.89829 0.00137 0.99695 -90 0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polarization | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com