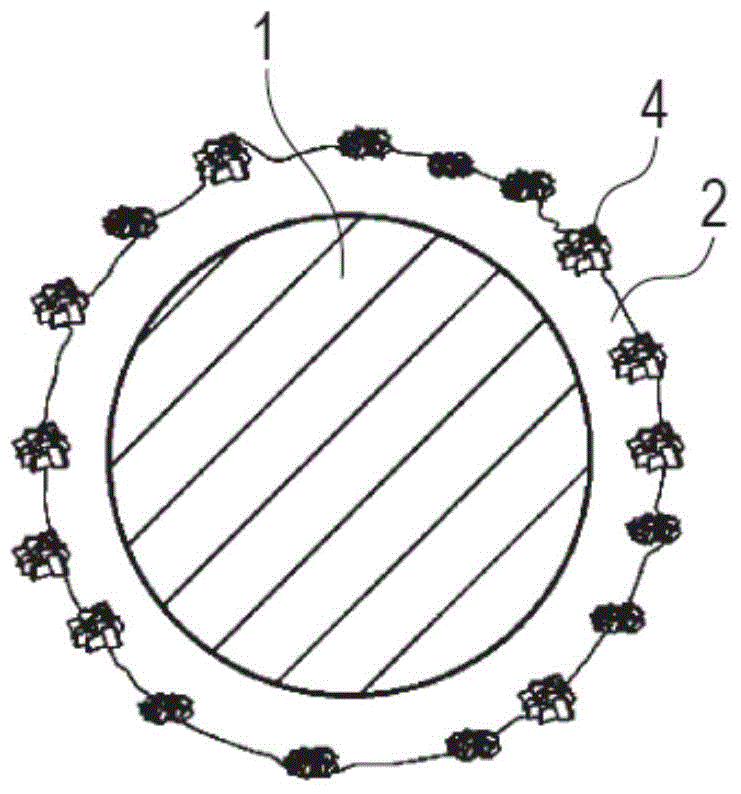

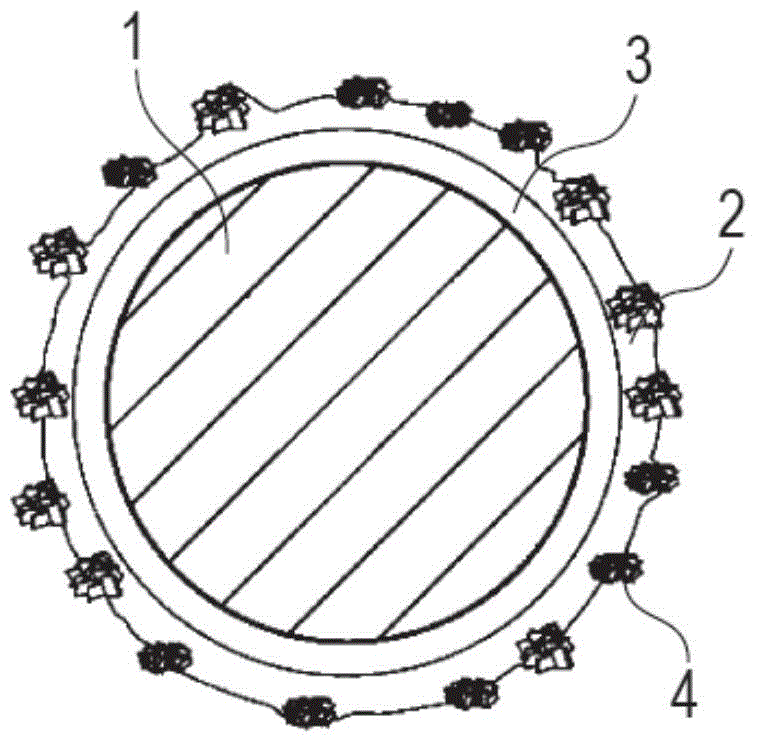

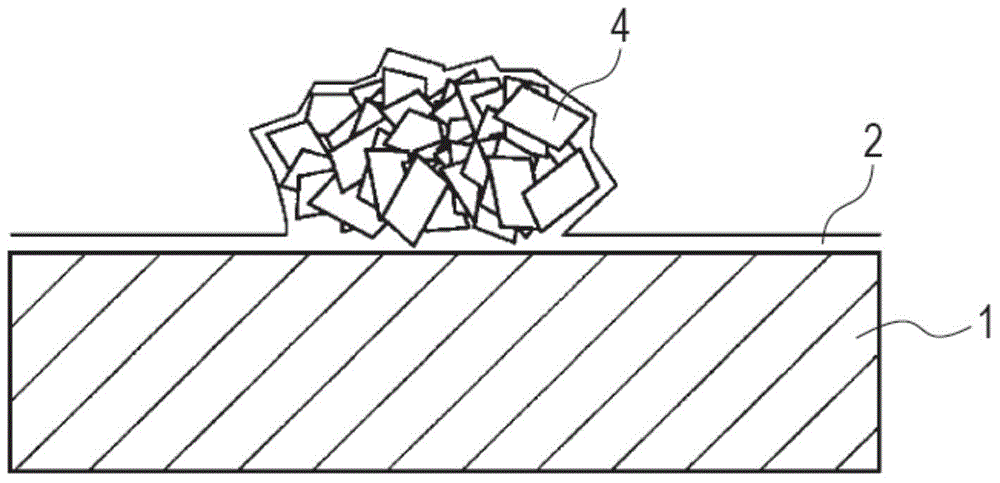

Electrophotographic member, process cartridge and electrophotography device

一种电子照相、构件的技术,应用在应用电荷图形的电记录工艺的设备、电气元件、电晕放电装置等方向,能够解决充电构件微小电阻不均、充电不均、污染等问题,达到抑制充电不均、改进从动旋转性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0213] (conductive substrate)

[0214] A thermosetting adhesive containing 10% by mass of carbon black was applied onto a substrate made of stainless steel having a diameter of 6 mm and a length of 252.5 mm and dried. The resulting substrate was used as a conductive substrate.

[0215] (conductive elastic layer)

[0216] By using an extruder equipped with a crosshead, the conductive substrate as the central axis was coaxially and cylindrically covered with the unvulcanized rubber composition R-1 produced in Production Example 42 to obtain mm outer diameter prefabricated body (preform).

[0217] The preform was heated and vulcanized at 160° C. for 1 hour in a hot air oven to form a conductive elastic layer on the outer periphery of the conductive substrate. An end portion of the conductive elastic layer was removed to obtain a roller having a conductive elastic layer having a length of 224.2 mm.

[0218] Then, the outer peripheral surface of the conductive elastic layer was...

Embodiment 2 to 47

[0231] The type of each unvulcanized rubber composition and the type of each surface layer coating liquid were changed as shown in Table 11. Further, each coating liquid for a surface layer was dried after coating under the conditions shown in Table 10.

[0232] Table 10

[0233]

[0234] Charging rollers T-2 to T-47 were produced in the same manner as in Example 1 except for the foregoing. Table 12 and Table 13 show the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com