Medical fabric with gaps between warps and wefts

A technology of fabrics and wefts, which is applied in the field of medical fabrics with gaps between warp and weft, which can solve the problems of uncomfortable wearing, easy to get dirty, and uncomfortable wearing, and achieve the effects of preventing blood penetration, improving smoothness, and not being easily stained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

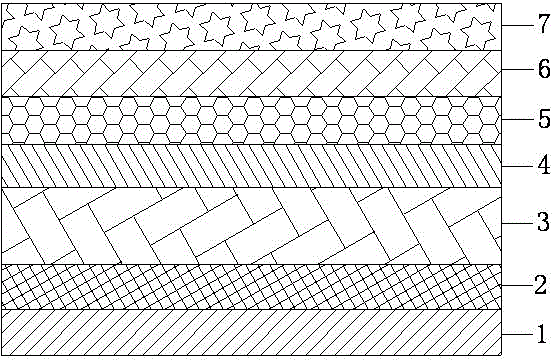

[0019] see figure 1 , the present invention relates to a medical fabric with gaps between the warp and weft threads, which includes a fabric body 1, the front of the fabric body 1 is covered with a polyurethane film 2, and the polyurethane film 2 has the characteristics of waterproof, breathable, transparent and visible, and antibacterial. The front side of the polyurethane film 2 is covered with a flax fiber layer 3. The flax fiber layer 3 has the characteristics of moisture absorption and heat dissipation, health care and antibacterial, antifouling and antistatic, anti-ultraviolet radiation, and gaps between high warp and weft threads. The flax fiber layer 3 The surface of the bamboo charcoal fiber layer 4 is covered with a layer of bamboo charcoal fiber layer 4. The bamboo charcoal fiber layer 4 has the characteristics of moisture absorption and drying, deodorization and antibacterial. , comfortable, breathable, quick-drying, etc., the surface of the moisture-absorbing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com