Vibrating type hanging screen

A vibrating, vibrating source technology, applied in the direction of filter screens, mobile filter element filters, grilles, etc., can solve the problems of reduced screening efficiency, repeated use of pumps, increased energy consumption, etc., to achieve high space utilization, The effect of reducing the workload of maintenance and prolonging the motion stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

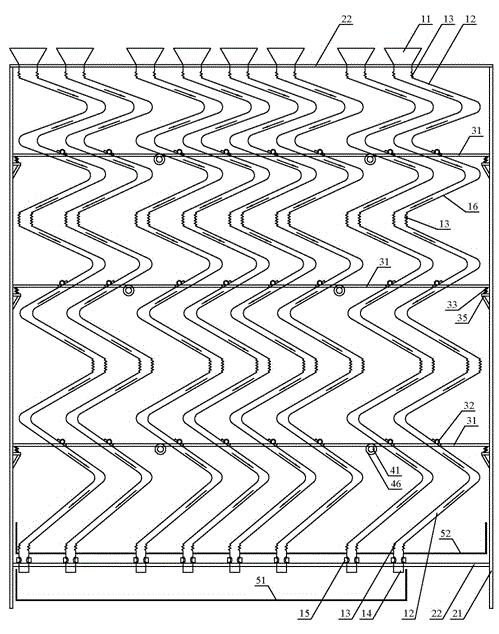

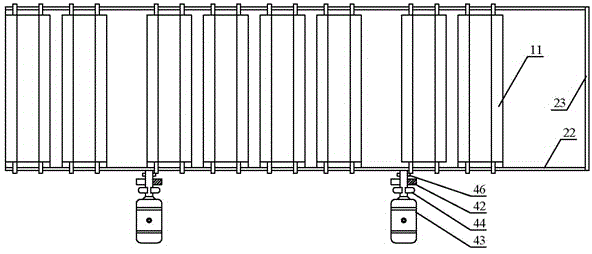

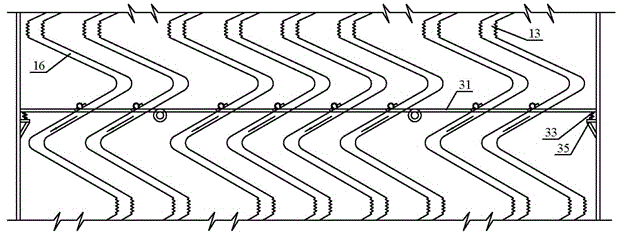

[0055] The vibrating hanging folding screen described in this embodiment is used for dehydrating ore pulp, including a frame, several screening units with the same string structure, a vibration transmission mechanism, a vibration excitation mechanism, a bottom chute 51, a support bottom groove 52 between strings, and a Splash curtain 53, such as figure 1 , 2 As shown, the arrow in the figure indicates the flow direction of the slurry on the screen.

[0056] The frame is formed by lapping columns 21, longitudinal beams 22 and crossbeams 23;

[0057] The screening unit includes a feeding cavity 11, a vibrating screen cavity 12, a buffer cavity 13 and a receiving cavity 14. Each cavity of the screening unit is a hollow structure surrounded by its surrounding sides; the screening unit is vertically The vibrating sieve chamber 12 is arranged in sections, and the inclined surface of the vibrating sieve chamber 12 is provided with a screen 16, and each section of the vibrating sie...

Embodiment 2

[0091] The vibrating hanging and folding screen described in this embodiment is used for wet screening, including a frame, several screening units with the same string structure, a vibration transmission mechanism, a vibration excitation mechanism, a chute at the bottom of the machine, a support bottom groove between strings, and a splash screen. , and water pipes, such as Figure 11 As shown, the arrow indicates the flow direction of the slurry on the screen.

[0092] Compared with Embodiment 1, the structural description of the vibrating folding screen in this embodiment only considers the differences in factors and the addition of water adding pipelines, and the similarities will not be repeated; the difference in considerations is that according to the wet screen The sub-process can dilute the slurry in the vibrating screen cavity to formulate the inclination angle of the corresponding downward inclined screen surface of the vibrating screen cavity.

[0093] According to ...

Embodiment 3

[0100] The vibrating hanging folding screen described in this embodiment is immersed in water for wet screening, including a frame, several screening units with the same string structure, vibration transmission mechanism, vibration excitation mechanism, machine bottom chute 51, support bottom groove 52 between strings, Anti-splash curtain 53, and water adding pipeline, such as Figure 13 As shown, the arrow in the figure indicates the flow direction of the slurry on the screen.

[0101] Compared with Embodiment 1 and Embodiment 2, the structural description of the third type of vibrating folding sieve differs in that: the support bottom groove between the strings and the vibrating screen cavity are arranged vertically one-to-one, and the splash-proof The curtain and the bottom slot between the strings are arranged one-to-one, thereby increasing and increasing the bottom slot between the strings to store the ore pulp. The splash curtain becomes segmented with the increase of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com