Electric active heave compensation winch system

A technology of heave compensation and winch, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of poor control accuracy and simple structure, and achieve the effect of simple structure and control, high control accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

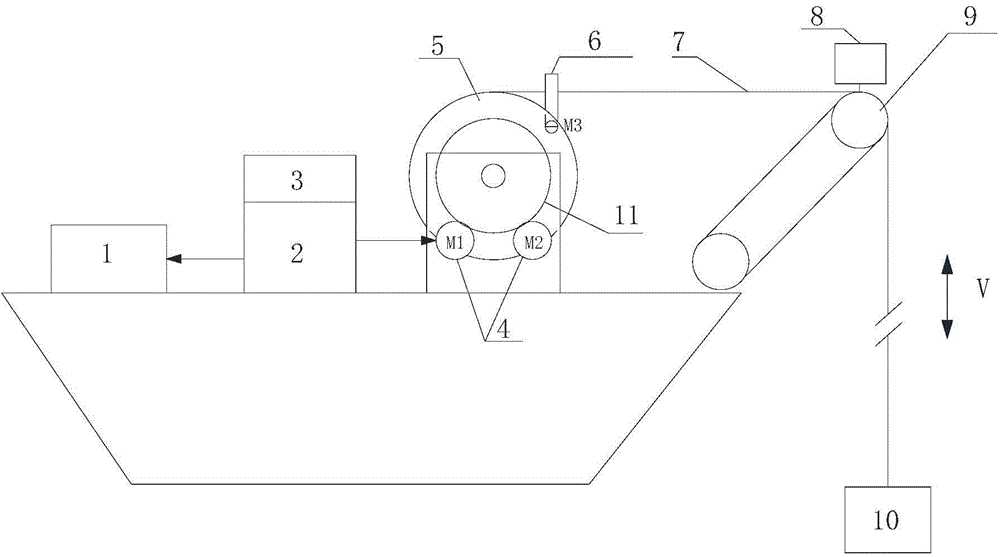

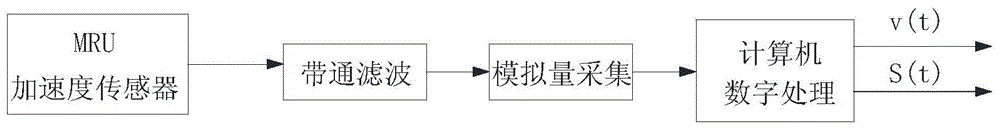

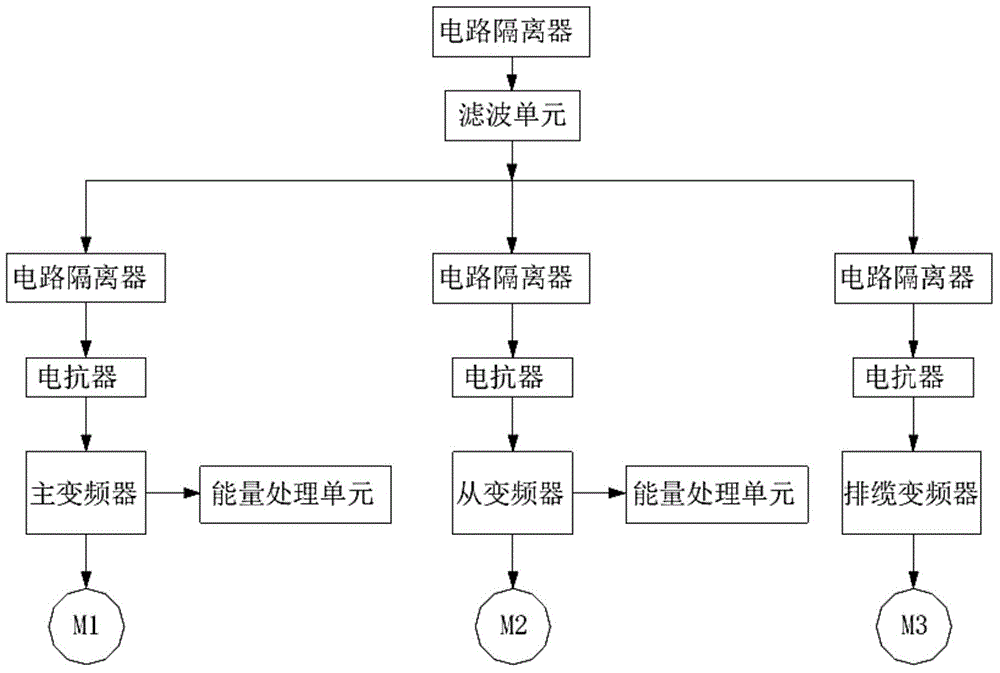

[0035] Such as figure 1 As shown, this embodiment includes: a cable discharge mechanism 6 arranged on the cable, a heave measuring unit 8 for measuring the heave velocity and heave displacement of the hoisting point 9 of the hoisting point 9 mechanism, and a winch connected to the winch driving motor Drive unit 2, winch controller 3, and energy processing unit 1 for recycling regenerative energy, wherein: the heave measurement unit 8 is connected to the winch controller 3 and outputs heave speed and displacement data, and the energy processing unit 1 and the winch The main circuit of the drive unit 2 is connected to regenerate regenerative energy. The control circuit of the winch drive unit 2 is connected to the winch controller 3 and transmits the motor encoder speed, number of turns and angle. The winch controller 3 calculates the angle and number of turns of the motor encoder according to And speed data, reduction ratio of reduction gear, heave speed and displacement data, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com