Acid dye leveling agent

A technology of acid dyes and leveling agents, applied in dyeing, textile and papermaking, etc., can solve the problems of poor biodegradable surfactants, human harmfulness, environmental impact, etc., and achieve environmental protection and biocompatibility. Good performance and easy biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] For the acid dye dyeing leveling agent 1 formula, the composition is as follows in parts by weight:

[0030]

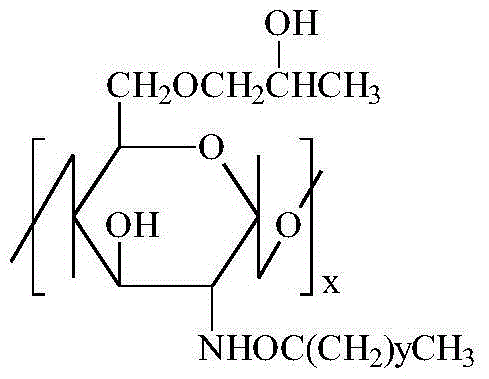

[0031] The N-fatty acylated-O-hydroxypropyl chitosan structure used is as follows:

[0032]

[0033] Wherein: x=200 (polymerization is the mixture of 100~300); y=8

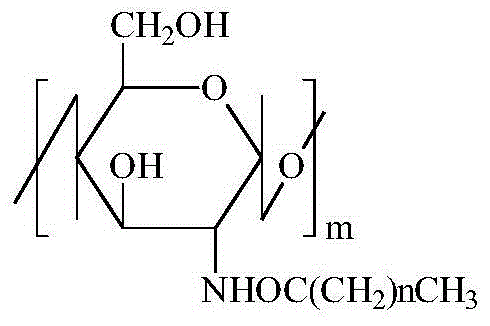

[0034] The N-fatty acylated chitosan oligosaccharide structure used is as follows:

[0035]

[0036] Wherein: m=5 (the mixture that degree of polymerization is 2~10); n=10

[0037] The cardanol polyoxyethylene ether structure used is as follows:

[0038]

[0039] Where: q is 15.

[0040] The N-fatty acylation-O-hydroxypropyl chitosan used in the present embodiment can be prepared by the following method: at first take chitosan as raw material, take isopropanol as solvent, tetramethylammonium hydroxide as catalyst, alkali O-hydroxypropyl chitosan was prepared by reacting with 1,2-propylene oxide under neutral conditions. Then use O-hydroxypropyl chitosan as a raw material, use a vol...

Embodiment 2

[0044] Acid dye dyeing leveling agent 2 formula is composed as follows in parts by weight:

[0045]

[0046] The N-fatty acylated-O-hydroxypropyl chitosan structure used is as follows:

[0047]

[0048] Wherein: x=200 (polymerization is the mixture of 100~300); y=6

[0049] The N-fatty acylated chitosan oligosaccharide structure used is as follows:

[0050]

[0051] Wherein: m=5 (the mixture that the degree of polymerization is 2~10); n=8

[0052] The cardanol polyoxyethylene ether structure used is as follows:

[0053]

[0054] Where: q is 20.

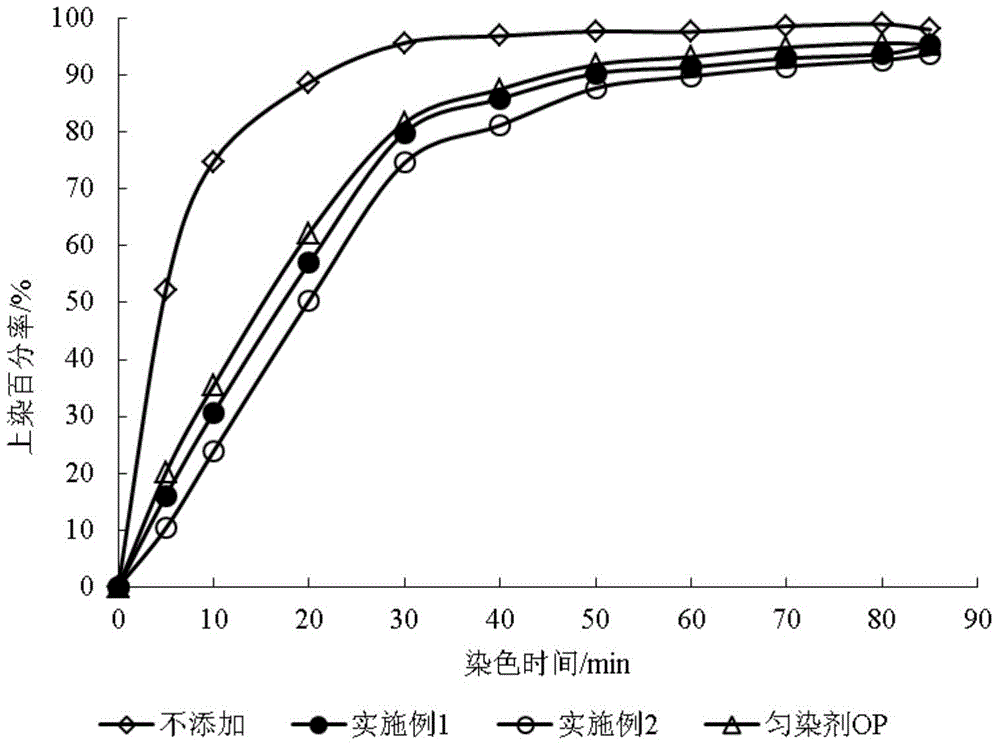

[0055]The acid dye leveling agent of the present invention is used in the acid dyeing process of real silk fabrics, and is compared with the leveling agent OP. The dyeing process conditions are: Weak acid Brilliant Blue G 2% (o.w.f.), the pH of the dye solution is 4.5, the leveling agent is 1g / L, the bath ratio is 50:1, the dyeing is done at 40°C, and the temperature is raised to 90°C at 2°C / min , keep warm for 60min....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com