LED lamp

A technology for LED lamps and metal lamp caps, which is applied in the direction of lampshades, cooling/heating devices of lighting devices, lighting and heating equipment, etc. Incandescent light distribution effect and other problems, to solve the problem of LED heat dissipation, meet the requirements of aesthetics, simple processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

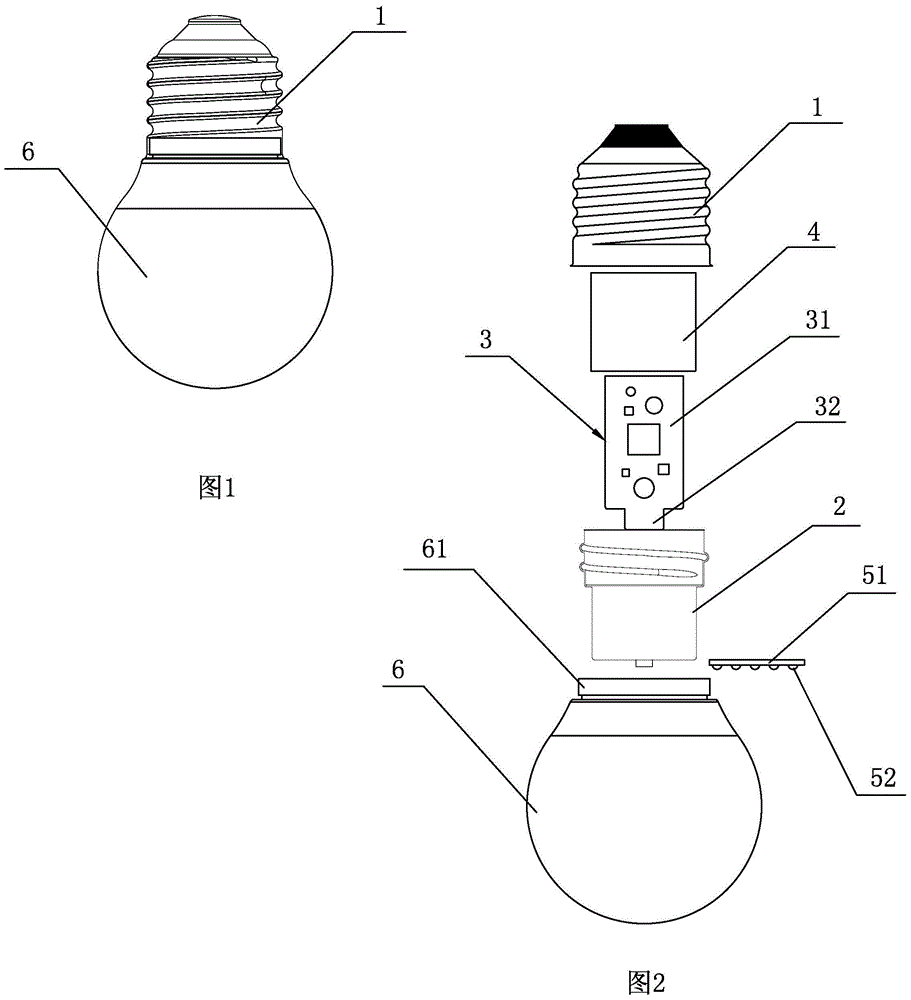

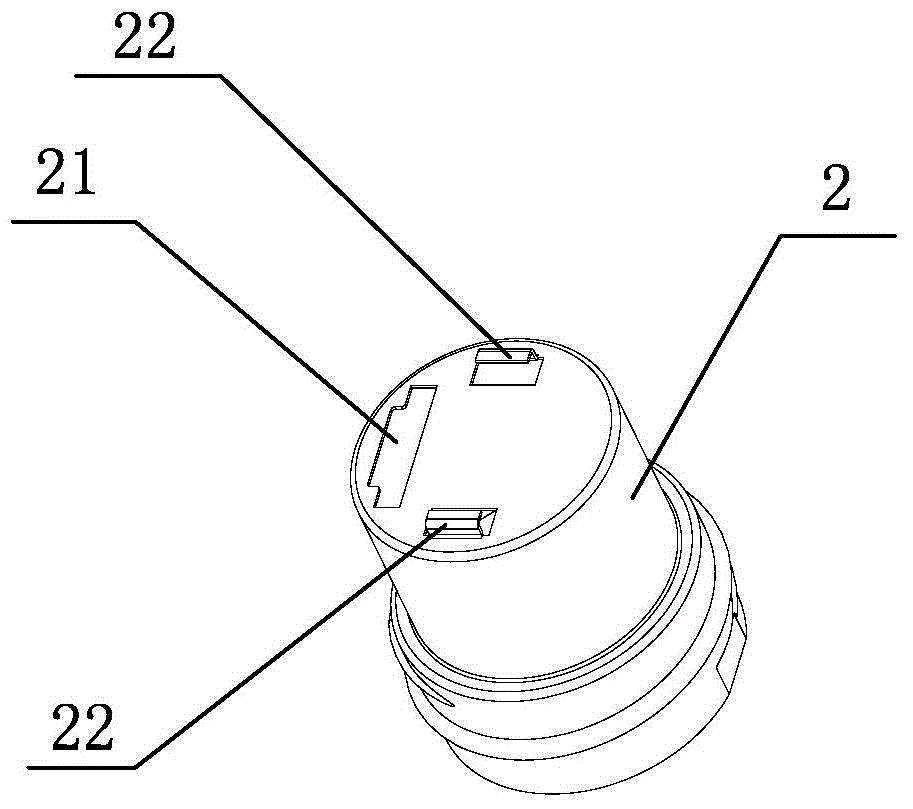

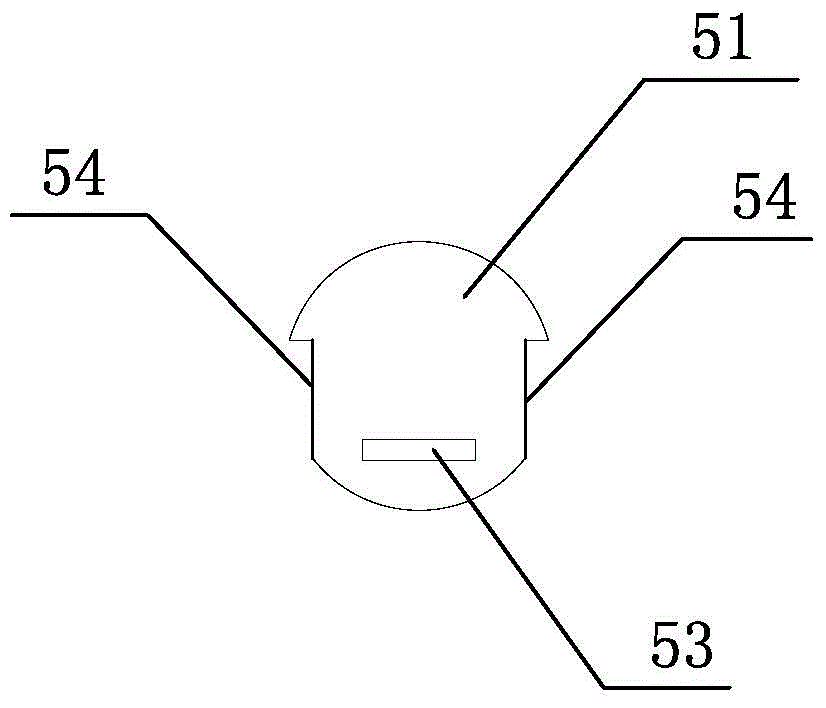

[0023] An LED lamp proposed by the present invention, as shown in the figure, includes a metal lamp cap 1, an aluminum heat sink 2, a driving power board 3, a hollow insulating protective cover 4 with an open bottom for protecting the driving power board 3, and a light source Components and PC bulb 6, the light source component is composed of a light source board 51 and several LED lamp beads 52 installed on the light source board 51; the aluminum heat sink 2 is hollow and the top is open, and the insulating protective cover 4 is set outside the drive power board 3 After the insulating protective cover 4 is set outside the driving power supply board 3, it is arranged in the aluminum forming radiator 2 through the top opening of the aluminum forming radiator 2, so that the insulating protective cover 4 is separated from the driving power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com