An Improved Ultrathin Loop Heat Pipe

A loop heat pipe, an improved technology, used in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large temperature and pressure fluctuations, high liquid cooling cost, small contact area, etc. The fluctuation of the machine is small, the operation is stable and reliable, and the effect of reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

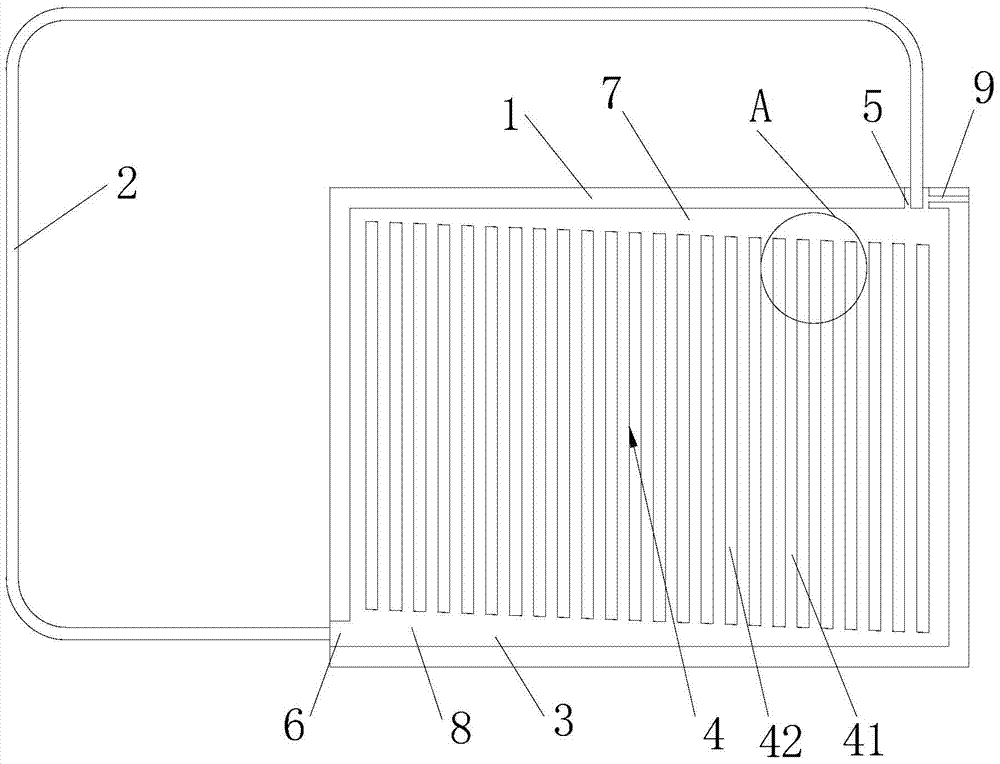

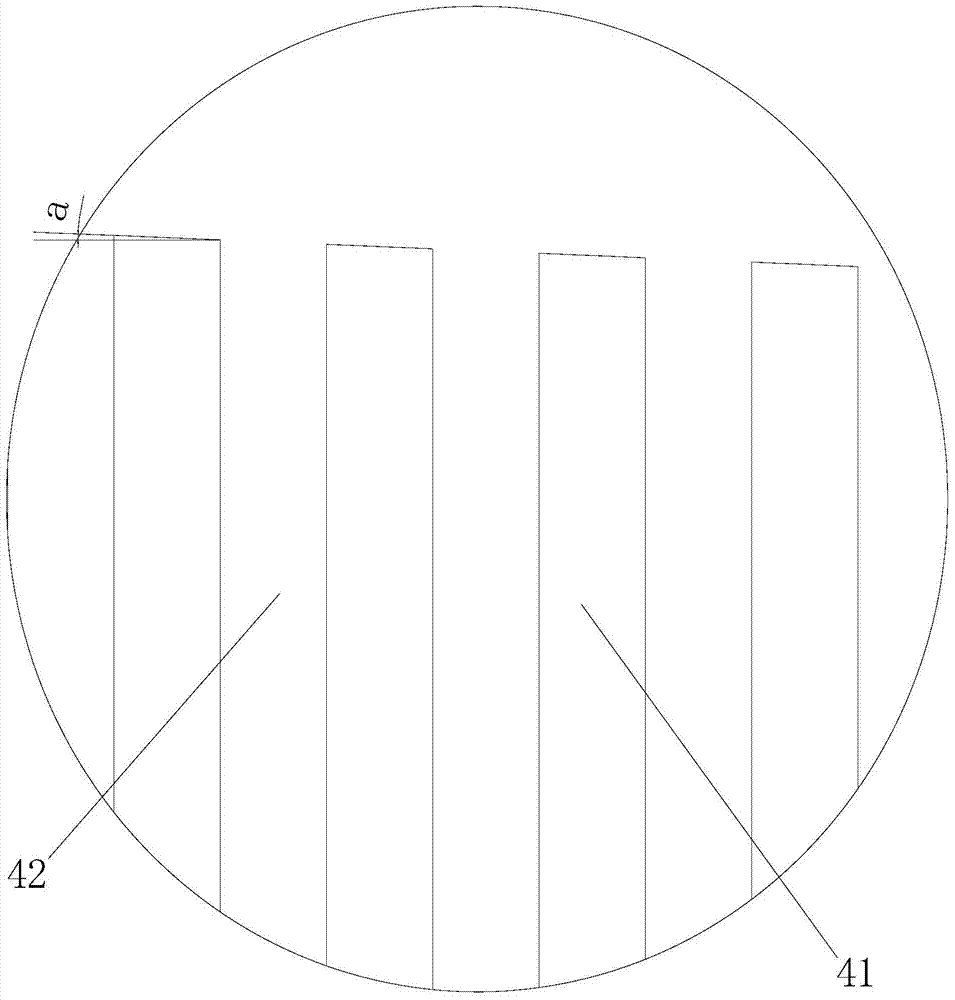

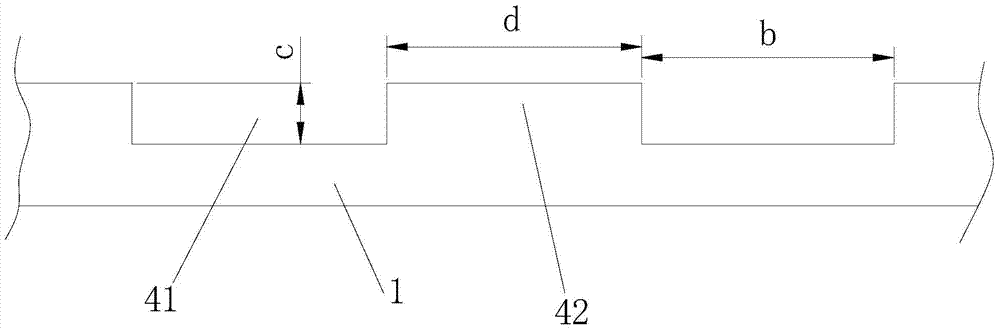

[0028] Such as Figure 1 to Figure 3 The improved ultra-thin loop heat pipe shown includes a metal base plate 1, a metal cover plate and an elbow 2, the metal base plate 1 is provided with a groove 3, and the edge of the metal base plate 1 is sealed with the edge of the metal cover plate connected, the metal cover plate covers the groove 3, the groove 3 is provided with a channel 4 with capillary action, and the two ends of the metal substrate 1 are respectively provided with a first communication port 5 and a second communication port 6 , the first communication port 5 and the second communication port 6 communicate with the groove 3, and the two ends of the elbow 2 are respectively connected to the first communication port 5 and the second communication port 6; the channels 4 are parallel Quadrilateral, above the channel 4 there is a vapor pool 7 with a gradually cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com