Spiral welded pipe twisted guided wave detection method and spiral welded pipe twisted guided wave detection device adopting spiral energy converter

A technology of spiral welded pipe and detection method, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., which can solve the problem of echo signal-to-noise ratio decline and achieve the effect of improving signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

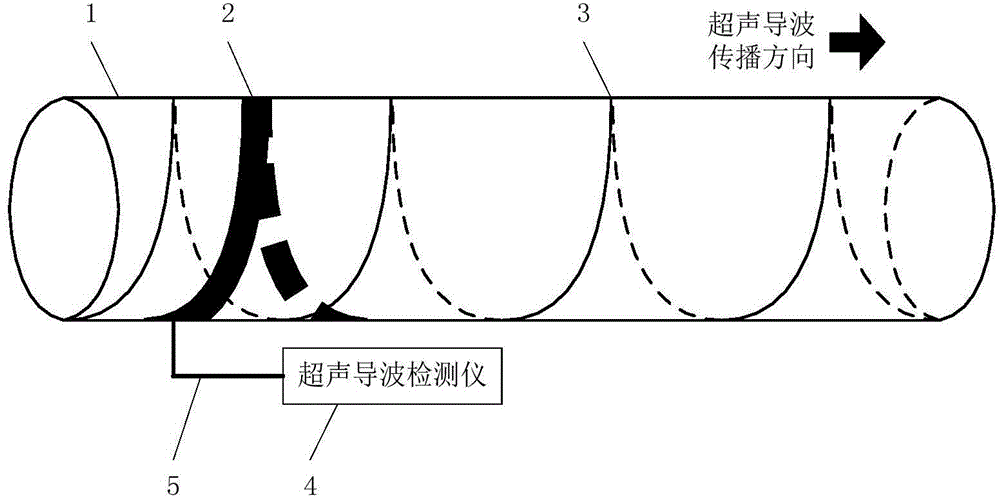

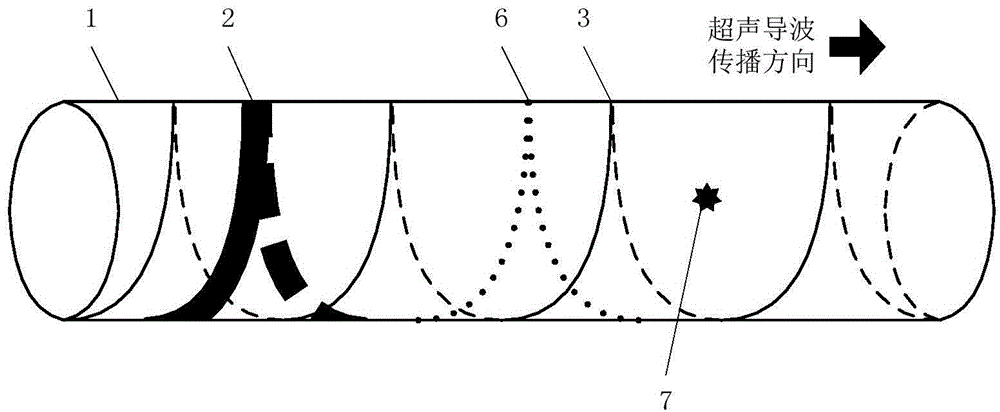

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

[0035] Method of the present invention comprises the following steps:

[0036] 1) According to the structural geometric parameters such as the outer diameter and wall thickness of the spiral welded pipe 1 and the material mechanical property parameters such as Young's modulus, Poisson's ratio, and density, the T(0,1) of the spiral welded pipe 1 is calculated by semi-analytical finite element method Dispersion properties of modal guided waves.

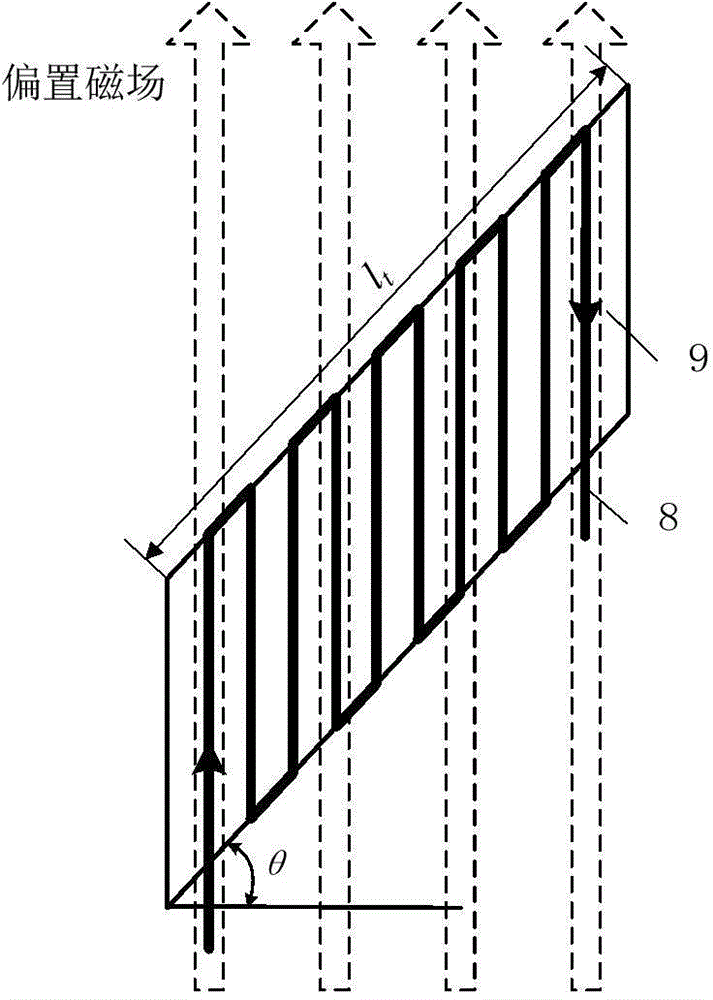

[0037] 2) According to the T(0,1) modal guided wave velocity and the helix angle of the spiral welded pipe 1, the frequency of the torsion-bending guided wave when the wave front is parallel to the spiral weld 2 is calculated. The specific formula is:

[0038] f = n c p T 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com