Transverse IGBT (Insulated Gate Bipolar Translator) and manufacturing method therefor

A manufacturing method and horizontal technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as IGBT characteristics deterioration, and achieve the effect of optimal electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

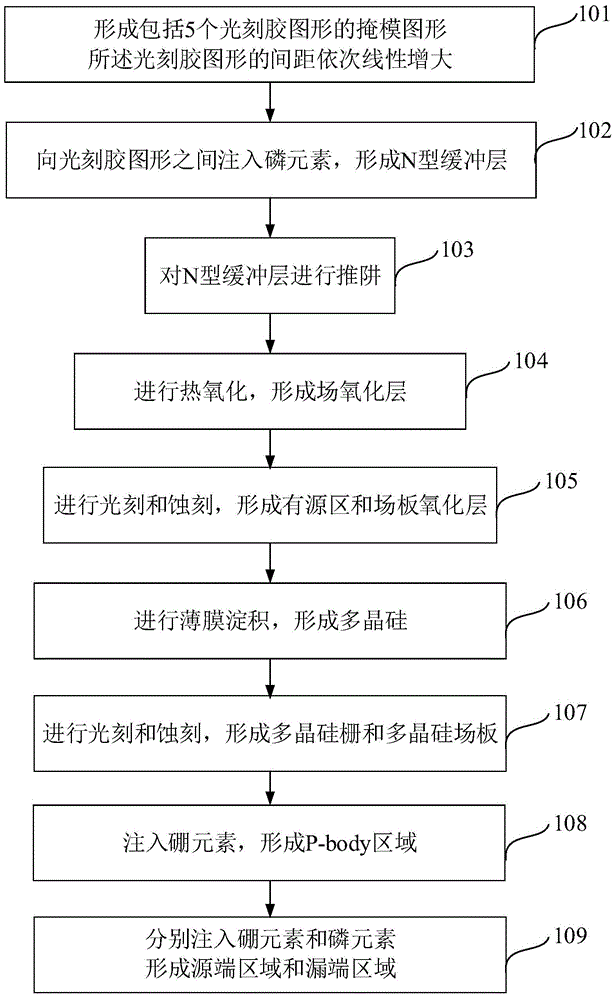

[0038] A method of making a horizontal IGBT, such as figure 1 shown, including the following steps:

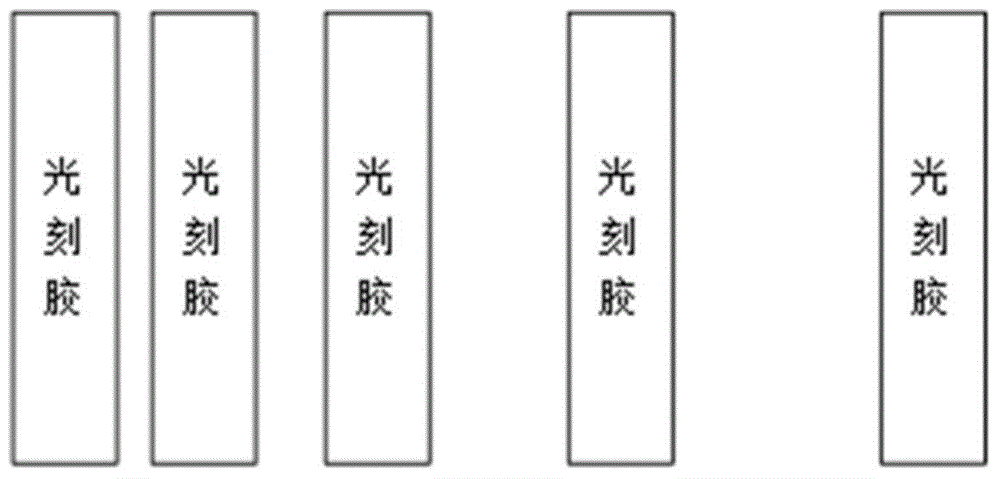

[0039] Step 101, forming a mask pattern, the mask pattern includes 5 photoresist patterns, such as figure 2 As shown, the pitch of the photoresist pattern increases linearly successively;

[0040] Step 102, injecting phosphorus elements between the photoresist patterns to form an N-type buffer layer;

[0041] Step 103, performing well pushing on the N-type buffer layer;

[0042] Step 104, performing thermal oxidation on a substrate to form a field oxide layer;

[0043] Step 105, performing photolithography and etching on the field oxide layer to form an active region and a field plate oxide layer;

[0044] Step 106, performing thin film deposition on the active region and the field plate oxide layer to form polysilicon;

[0045] Step 107, performing photolithography and etching on the polysilicon to form a polysilicon gate and a polysilicon field plate;

[0046] Step 10...

Embodiment 2

[0054] This embodiment provides a method for fabricating a lateral IGBT. The difference from the method of Embodiment 1 is that: in step 101, the length of the mask pattern is 100 microns, and the spacing of the photoresist pattern increases step by step; in step 102, Arsenic is injected between the photoresist patterns to form an N-type buffer layer; in step 109, boron and arsenic are injected respectively to form a source region and a drain region.

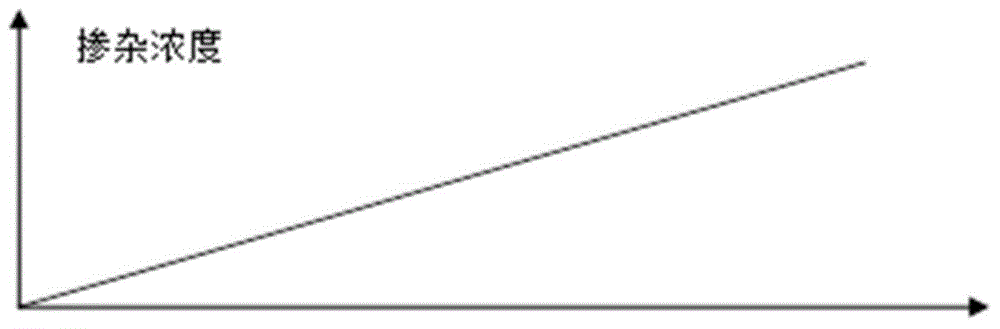

[0055] This embodiment also provides a 1200V lateral IGBT, which is manufactured by the above-mentioned manufacturing method, such as Figure 4 As shown, the doping concentration of the N-type buffer layer in the lateral IGBT is a stepwise distribution. Compared with the existing 1200V lateral IGBT, the lateral IGBT of this embodiment has better static characteristics, dynamic characteristics and switching characteristics.

[0056] It should be noted that the number and spacing of the photoresist patterns are determined by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com