Piezoelectric linear motor fused with shear piezoelectric actuator composite drive mode

A linear motor, driving mode technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. , difficult and precise positioning and other problems, to overcome the effects of sub-micron and nano-precision positioning, simple structure and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

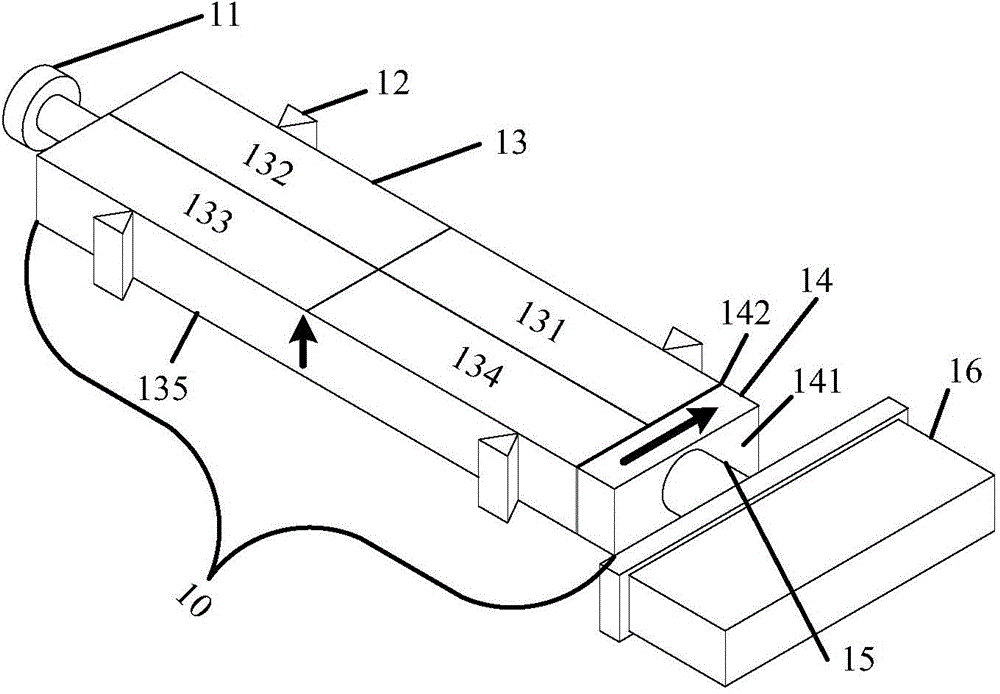

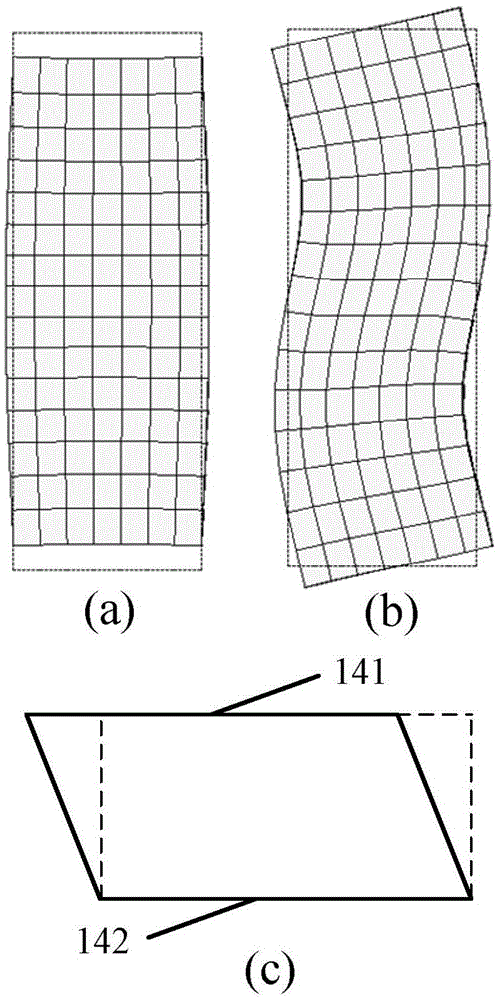

[0050] In the first embodiment, the piezoelectric motor transducer works in the first-order elongation (L1) and second-order bending (B2) modes. The structural size of the piezoelectric transducer 13 needs to be designed according to the condition that the resonant frequencies of the L1 and B2 modes are equal, and it is required that the L1 and B2 modes can be excited at the same time to design and divide the electrodes. During design, by adjusting the aspect ratio of the piezoelectric transducer 13, the frequencies of the L1 mode and the B2 mode are consistent. At the same time, if figure 1 As shown, the piezoelectric transducer 13 as a whole is polarized along the thickness direction (as figure 1 shown in ↑), and its upper surface electrode is divided into the first electrode area 131, the second electrode area 132, the third electrode area 133 and the fourth electrode area 134 four parts of the same rectangular area, the lower surface electrode is an integrated structure ...

Embodiment 2

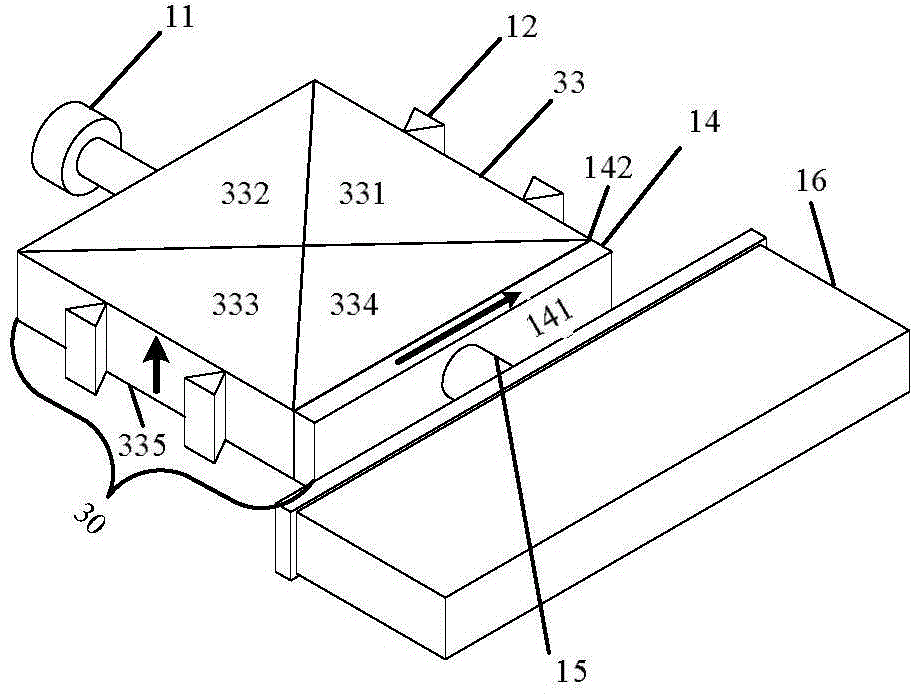

[0056] In the second embodiment, the piezoelectric motor works in the isomorphic first-order in-plane bending (B1B1) mode, and the piezoelectric transducer 33 needs to be designed as a square to ensure that the two isomorphic B1 modes are excited at the same operating frequency. At the same time, if image 3 As shown, the whole piezoelectric transducer 33 is polarized along the thickness direction (as image 3 shown in ↑), and the electrodes on the upper surface of the piezoelectric transducer 33 are divided into the first electrode area 331, the second electrode area 332, the third electrode area 333 and the fourth electrode area 334 along the diagonal line on the upper surface of the piezoelectric transducer 33. The four parts have the same area, and the bottom surface electrode is an integrated fifth electrode area 335 . The electrode areas 331, 332, 333 and 334 on the upper surface of the piezoelectric transducer 33 can be connected to the piezoelectric motor drive circui...

Embodiment 3

[0062] In the third embodiment, the piezoelectric motor transducer 53 works in the first-order in-plane diagonal bending (FDB) vibration mode of the same shape, and the piezoelectric transducer 53 needs to be designed as a square to ensure that the two same-shaped FDB modes operate at the same frequency. is excited. At the same time, if Figure 5 As shown, the piezoelectric transducer 53 as a whole is polarized along the thickness direction (as Figure 5 shown in ↑), and the upper surface electrode is divided into four parts of the same square area as the first electrode area 531, the second electrode area 532, the third electrode area 533 and the fourth electrode area 534, and the lower surface electrode has an integral structure The fifth electrode region 535 . The electrode areas 531, 532, 533 and 534 on the upper surface of the piezoelectric transducer 53 can be connected to the piezoelectric motor drive circuit to provide an AC input voltage of a specific frequency, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com