Motor control method, device and motor system

A motor control and controller technology, applied in the field of control, can solve problems such as winding temperature rise and motor speed characteristics poorness, achieve the effect of increasing motor speed, solving winding temperature rise, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

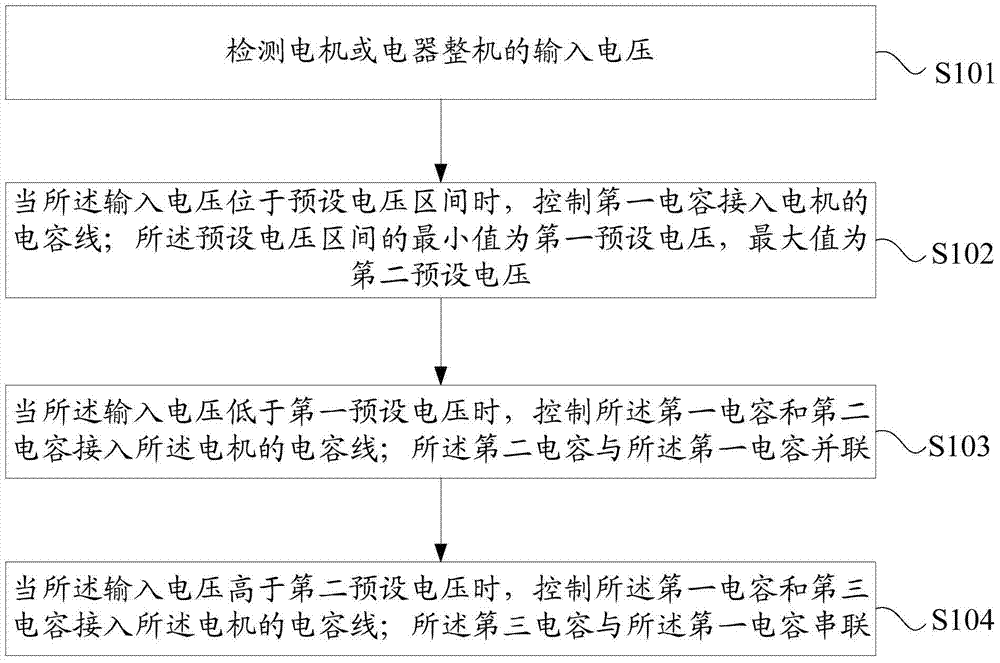

[0055] see figure 1 , figure 1 It is a flow chart of a motor control method provided by an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0056] Step S101, detecting the input voltage of the motor or the complete electrical appliance;

[0057] Specifically, the input voltage of the motor in the electrical appliance is equal to the input voltage of the electrical appliance, and any one of them can be detected.

[0058] Step S102, when the input voltage is in a preset voltage range, control the first capacitor to be connected to the capacitor line of the motor; the minimum value of the preset voltage range is the first preset voltage, and the maximum value is the second preset voltage ;

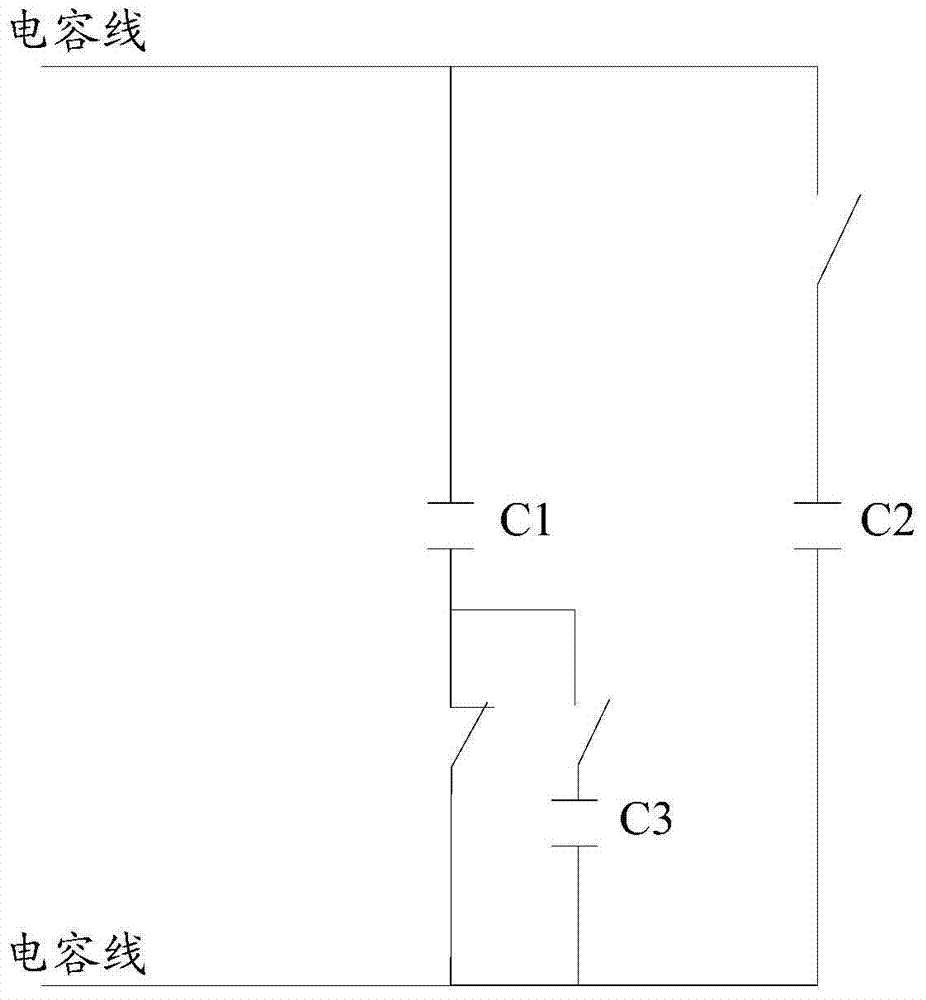

[0059] Specifically, see figure 2 , figure 2 It is a structural diagram of a motor capacitance control circuit provided by an embodiment of the present invention. Such as figure 2 As shown, the first capacitor C1 can be connected to the capaci...

Embodiment 2

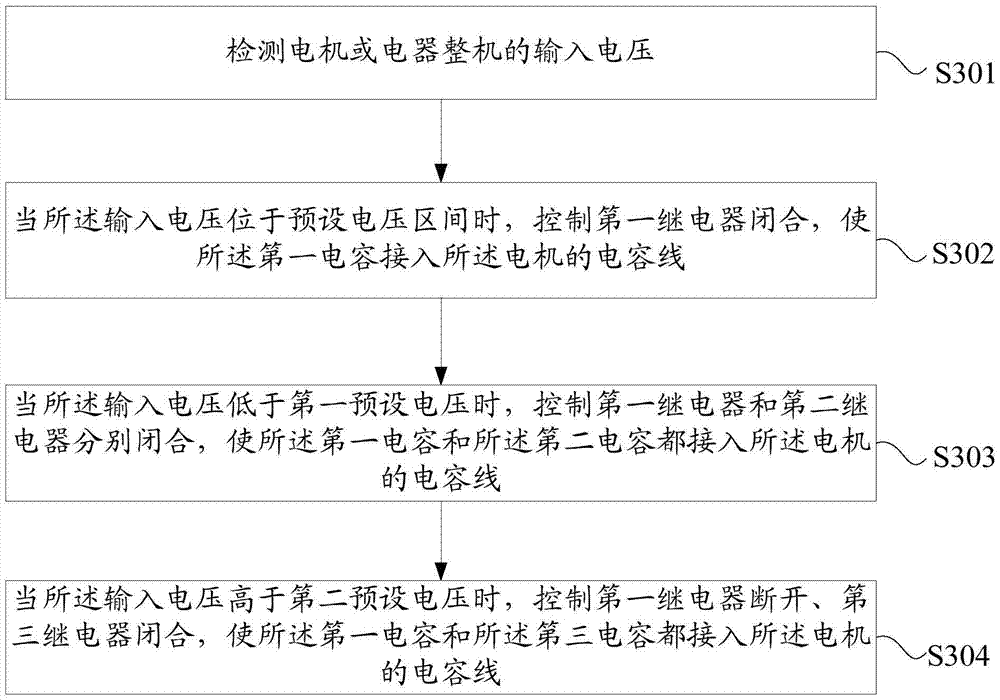

[0067] see image 3 , image 3 It is a flow chart of another motor control method provided by the embodiment of the present invention. Such as image 3 As shown, the method includes:

[0068] Step S301, detecting the input voltage of the motor or the complete electrical appliance;

[0069] Step S302, when the input voltage is within a preset voltage range, control the first relay to close, so that the first capacitor is connected to the capacitor line of the motor, and the first relay is connected in series with the first capacitor;

[0070] Step S303, when the input voltage is lower than the first preset voltage, control the first relay and the second relay to close respectively, so that both the first capacitor and the second capacitor are connected to the capacitor line of the motor; The first relay is connected in series with the first capacitor, and the second relay is connected in series with the second capacitor;

[0071] Step S304, when the input voltage is higher...

Embodiment 3

[0074] see Figure 4 , Figure 4 It is a flow chart of another motor control method provided by the embodiment of the present invention. Such as Figure 4 As shown, the method includes:

[0075] Step S401, detecting the input voltage of the motor or the complete electrical appliance;

[0076] Step S402, when the input voltage is in the preset voltage range, control the normally closed contact of the fourth relay to maintain a closed state, so that the first capacitor is connected to the capacitor line of the motor, and the normally closed contact of the fourth relay is The closed contact is connected in series with the first capacitor;

[0077] Step S403, when the input voltage is lower than the first preset voltage, control the normally closed contact of the fourth relay to maintain a closed state, connect the first capacitor to the capacitor line of the motor, and control the fifth relay The relay is closed, so that the second capacitor is connected to the capacitor lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com