Graphite substrate and manufacture method thereof, LED module and manufacture method thereof

A technology of a graphite substrate and a manufacturing method, applied in the field of LED lamps, can solve the problems of cracking of graphite sheets, restricting the use of substrates, unable to be made into flexible circuit boards, etc., and achieving the effects of simple manufacturing process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

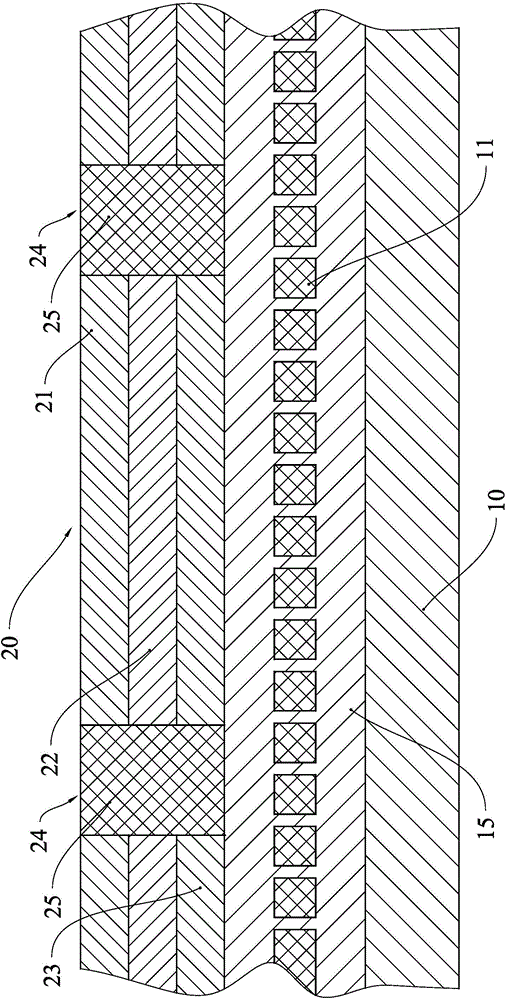

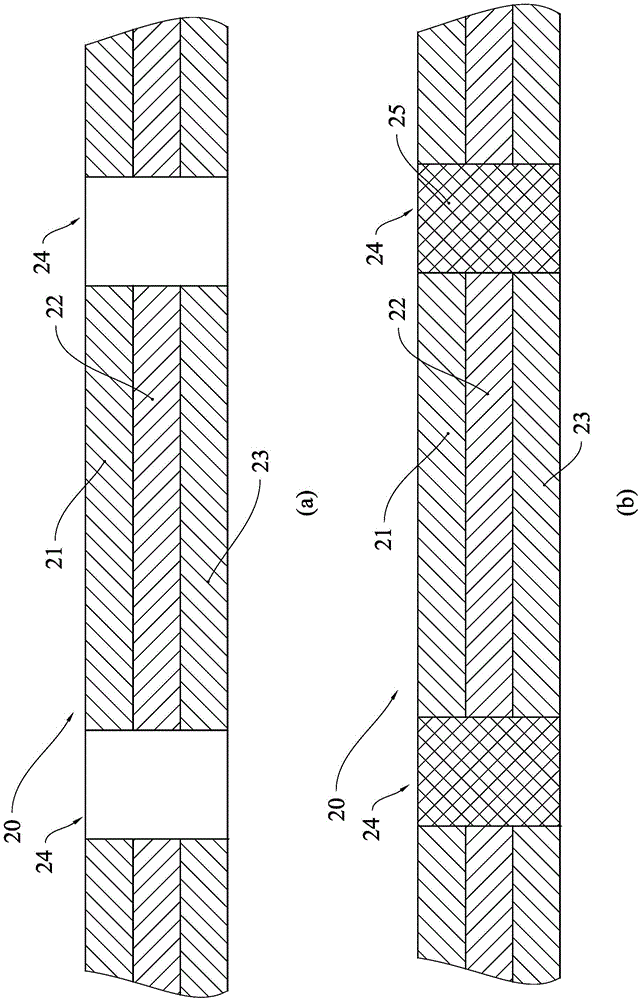

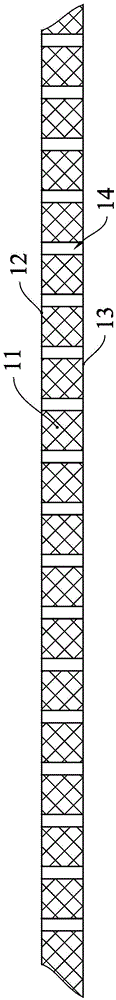

[0033] see figure 1 , the graphite substrate of this embodiment includes a metal layer 20, a graphite sheet 11, an adhesive 13 and a heat dissipation layer 10, wherein the heat dissipation layer 10 is located at the lowermost end of the graphite substrate, the graphite sheet 11 is located above the heat dissipation layer 10, and the metal layer 20 is located at the bottom of the graphite substrate. Above the graphite sheet 11 , the graphite sheet 11 and the heat dissipation layer 10 are connected by an adhesive 15 , and the metal layer 20 and the graphite sheet 11 are also connected by an adhesive 15 . The heat dissipation layer 10 in this embodiment is a substrate made of a material with good heat dissipation capability, such as a copper clad laminate, an aluminum plate, or a ceramic plate. Adhesive glue 15 preferably uses polypropylene (PP material).

[0034] The graphite sheet 11 that present embodiment uses is flexible graphite sheet, preferably, selects the flexible grap...

no. 2 example

[0044] see Figure 4 , the graphite substrate of the present embodiment includes a heat dissipation layer, a heat conduction pad 38 positioned above the heat dissipation layer, a graphite sheet 35 positioned above the heat conduction pad 38, a metal layer 42 positioned above the graphite sheet 35, and a pass between the metal layer 42 and the graphite sheet 35 Adhesive glue 40 connects. Different from the first embodiment, the lower part of the graphite sheet 35 is not connected to the heat dissipation layer by adhesive glue, but is connected by a thermal pad 38 . The heat conduction pad in this embodiment is an elastic pad made of heat conduction rubber or the like.

[0045] The heat dissipation layer of this embodiment is a metal or ceramic radiator 30, the lower end of the radiator 30 has a plurality of protrusions 31 extending downward, and a heat dissipation groove 32 is formed between two adjacent protrusions 31, and the protrusions 31 and heat dissipation The surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com