Method and apparatus for purifying organic material using ionic liquid

An ionic liquid and organic material technology, which is applied in the field of organic material purification and purification device using ionic liquid, can solve the problems of high price of OLED organic materials, and achieve the effects of simple structure, realization of manufacturing process and improvement of purification yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

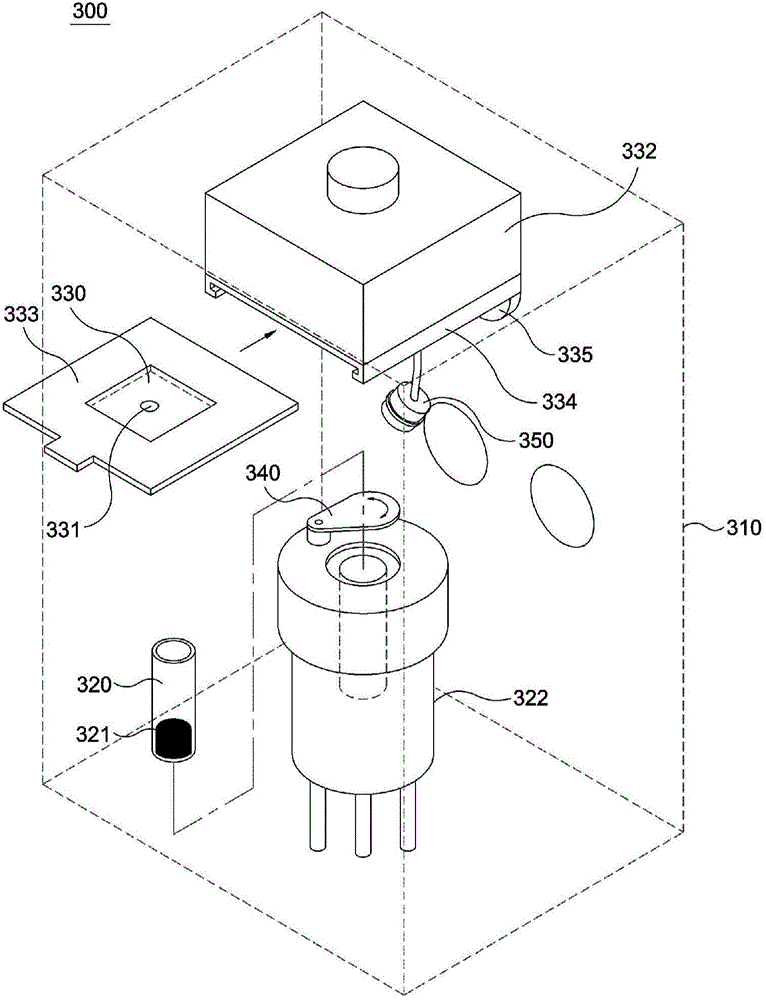

[0077] image 3 It is a perspective view showing the structural relationship of a simple purification device for organic materials using ionic liquids according to the first embodiment of the present invention. Such as image 3 As shown, the simple organic material purification device 300 according to this embodiment generally includes: a sublimation means for sublimating the organic material raw material; a recrystallization means for recrystallizing the sublimation gas of the sublimated organic material in an ionic liquid; Analytical means for photographing and analyzing purified materials recrystallized in the liquid; and control means for controlling the operation of sublimation means, recrystallization means, and analysis means as a whole.

[0078] According to the ionic liquid of the present embodiment, 1-butyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide (1-Butyl-3-methylimidazorium bis(trifluoromethylsulfonyl)imide) (BMIM TFSI), or 1-octyl-3-methylimidazoli...

no. 2 Embodiment

[0103] Figure 5 It is a conceptual diagram of the structural relationship of the organic material purification apparatus using ionic liquid according to the second embodiment of the present invention. Such as Figure 5 As shown, the organic material purification device 500 of this embodiment includes: a sublimation means in a vacuum atmosphere that heats and sublimates OLED organic material raw materials containing impurities; mixes the sublimation gas of the sublimated organic material into the ionic liquid, and recrystallizes in the ionic liquid The recrystallization means of the vacuum atmosphere; and the control means for controlling the operation of the sublimation means and the recrystallization means.

[0104] Here, the sublimation means includes: a crucible 510 containing an organic material raw material 511; a heating cavity 520 with a certain internal volume provided with the crucible 510; a vacuum pump 550 for pumping the inside of the heating cavity 520 into a va...

no. 3 Embodiment

[0124] Figure 7 It is a conceptual diagram of the structural relationship of the organic material purification apparatus using ionic liquid according to the third embodiment of the present invention. Such as Figure 7 As shown, according to the organic material purification device 500A of this embodiment, in order to enable smooth recovery of the purified material 543A, it is the same as that of the organic material of the second embodiment except that the form of the storage tank 540A and the configuration of the third heater 542A are partially changed. The material purification device 500 has the same configuration. Therefore, in the present embodiment, the same reference numerals are used for the same components, and their descriptions are omitted.

[0125] The lower part of the storage tank 540A of this embodiment is formed in the form of a funnel, and the lower part has a recovery bucket 544 for the purification material 543A alone. At this time, the recovery bucket 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sublimation point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com