A kind of cobalt, titanium oxide heterojunction material and preparation method thereof

A titanium oxide and heterojunction technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of non-functional, non-toxic and harmless dyes , does not meet the problems of industrial and ecological sustainable development, and achieves the effect of easy weighing, simple equipment requirements, and good visible light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

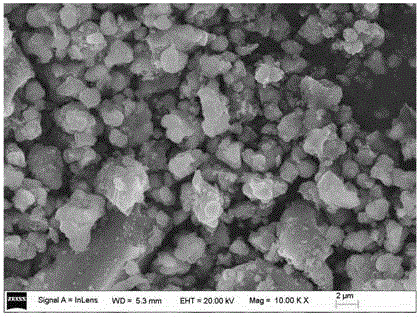

[0029] Weigh 2.328g of cobalt nitrate hexahydrate and 2.880g of titanium sulfate, dissolve them in 100mL of deionized water, transfer the completely dissolved solution of cobalt nitrate and titanium sulfate to a 500mL round bottom flask, heat in an oil bath at 100°C, stir, condense and reflux , A solution was obtained in 30 min.

[0030] Then weigh 15.360g of ammonium carbonate and dissolve it in 50mL of deionized water to obtain solution B. The molar ratio of ammonium carbonate to the sum of cobalt ions and titanium ions is 4.9:1.

[0031] All solution A was dropped into the ammonium carbonate solution drop by drop, reacted for 5 hours, centrifugally filtered, washed, and dried at 60°C.

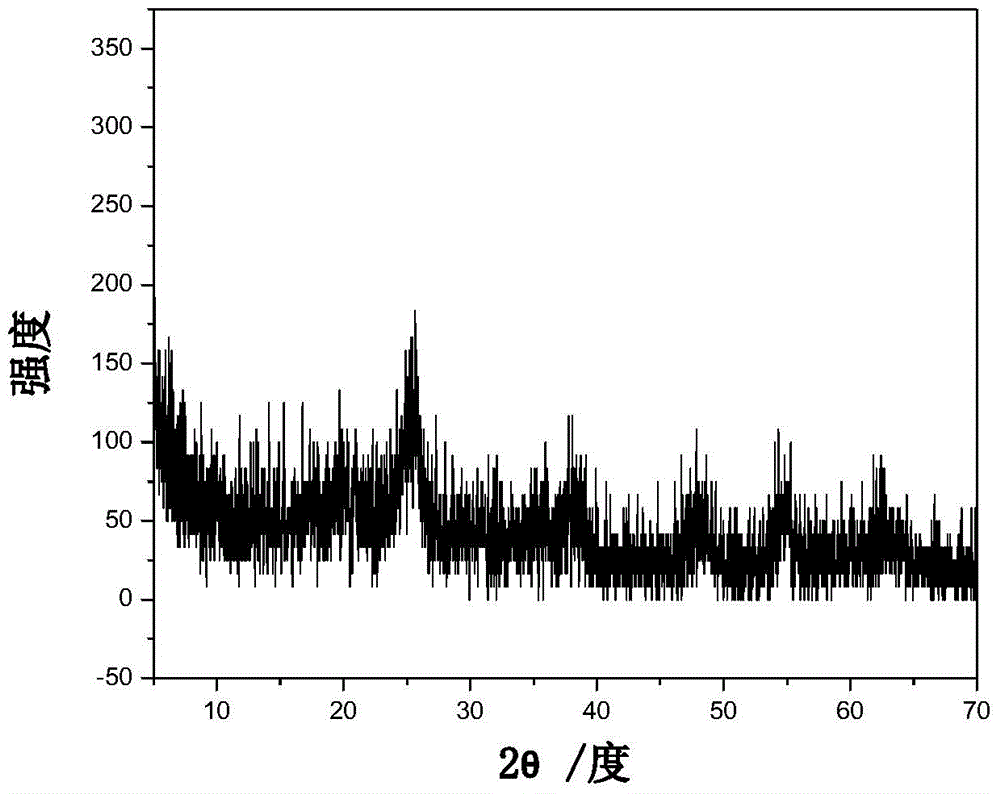

[0032] Baking at 400°C for 4 hours in a muffle furnace to obtain a heterojunction of cobalt and titanium oxides. Wherein Co / Ti=2mol:3mol, and the mass percentage of cobalt is 45%.

[0033] Weigh 0.020g of the above-mentioned cobalt and titanium oxide heterojunction and add it to 100mL of 1...

Embodiment 2

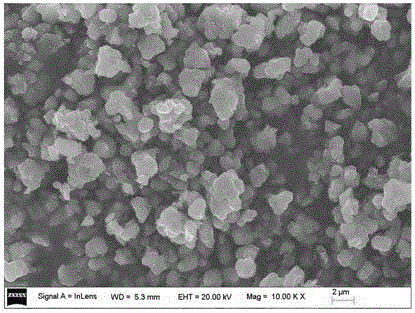

[0035] Weigh 2.328g cobalt nitrate hexahydrate, 7.680g titanium sulfate, dissolve in 100mL deionized water, then weigh 28.260g ammonium carbonate and dissolve in 50mL deionized water. Transfer the completely dissolved solution of cobalt nitrate and titanium sulfate to a 500mL round-bottomed flask, heat in an oil bath at 110°C, stir, condense and reflux, and after 25 minutes, add the solution of ammonium carbonate dropwise, the mixture of ammonium carbonate and cobalt ions and titanium ions and the molar ratio of 4.5:1. After reacting for 5 h, the solution was centrifuged, washed, and dried at 60°C. Calcined in a muffle furnace at 500° C. for 5 hours to obtain a cobalt-titanium oxide heterojunction with a cobalt content of 23% by mass.

Embodiment 3

[0037] Weigh 2.328g cobalt nitrate hexahydrate, 5.760g titanium sulfate, dissolve in 100mL deionized water, then weigh 26.120g ammonium carbonate and dissolve in 50mL deionized water. Transfer the completely dissolved solution of cobalt nitrate and titanium sulfate to a 500mL round-bottomed flask, heat in an oil bath at 100°C, stir, condense and reflux, and after 15 minutes, add the solution of ammonium carbonate dropwise, the mixture of ammonium carbonate and cobalt ions and titanium ions and the molar ratio of 5.2:1. After reacting for 7 hours, the solution was centrifuged, washed, and dried at 60°C. Calcined in a muffle furnace at 450° C. for 2 hours to obtain cobalt and titanium oxides with Co / Ti=1 mol:3 mol and a mass percentage of cobalt of 29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com