Magnetic-Floatation Separation Process of Micro-fine-grained Magnetic-Red Mixed Ore

A technology for mixing ore and fine particles, applied in flotation, magnetic separation, solid separation, etc., can solve the problems of increasing the dosage of flotation reagents and beneficiation costs, large consumption of flotation reagents, and increasing the processing capacity of flotation operations. , to reduce the number of flotation machines, improve the sorting effect, and reduce the effect of crushing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

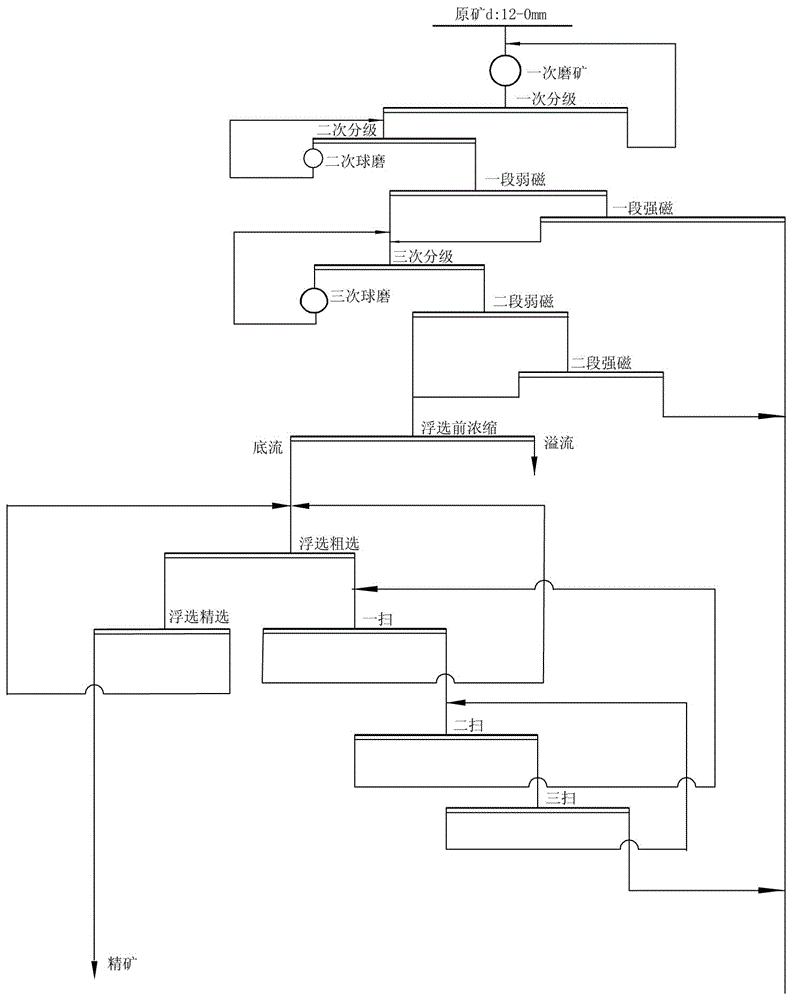

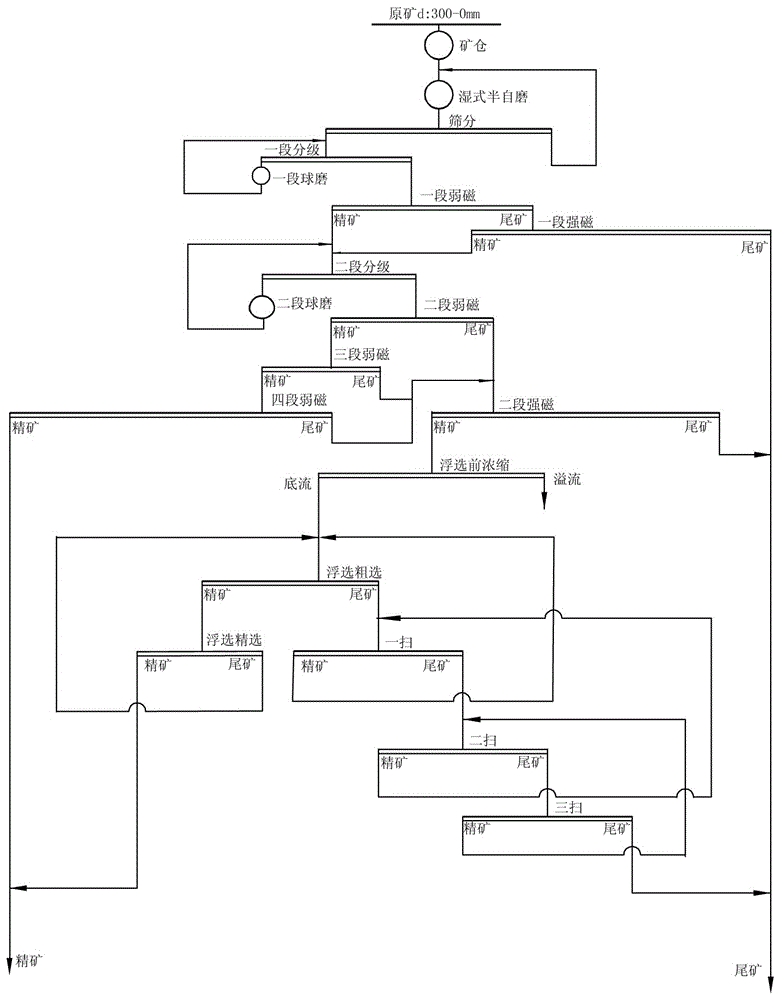

[0025] like figure 2 As shown, the magnetic-flotation separation process of a kind of fine-grained magnetic-red mixed ore of the present invention adopts wet semi-self-grinding, stage grinding, stage-weak magnetic-strong magnetic, strong magnetic concentrate The reverse flotation process, the anion reverse flotation operation adopts a closed-circuit system of one-stage flotation roughing, one-stage flotation concentration, and three-stage flotation sweep ratio, which is characterized in that it includes the following steps:

[0026] a) Raw ore with a grade of 31% to 33%, a magnetic iron content of 40 to 60%, and a particle size of less than 300mm is fed into the wet semi-autogenous grinding-screening operation through the ore storage bin, and the -3mm product under the screen is fed into a closed circuit The grinding and grading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com