Automatic cleaning device

An automatic cleaning and pipeline technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of high labor costs and low cleaning efficiency, achieve high automation, easy operation, and reduce Effects of Labor Intensity and Labor Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

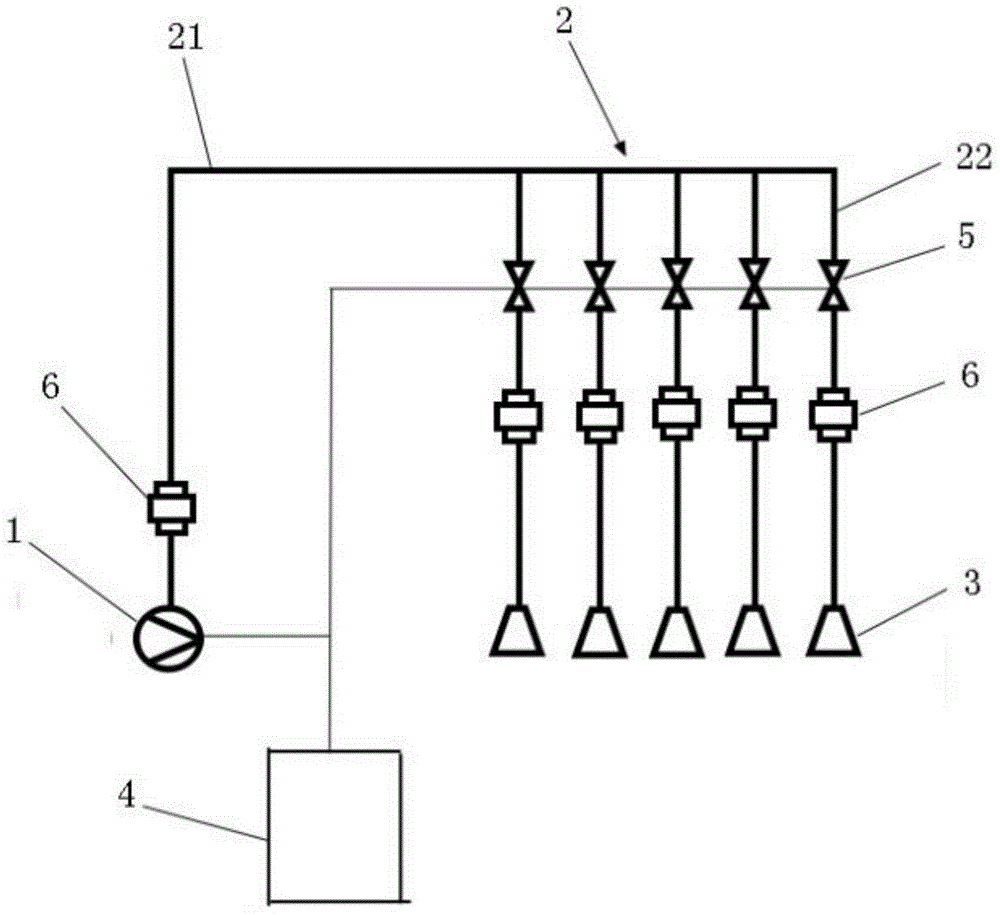

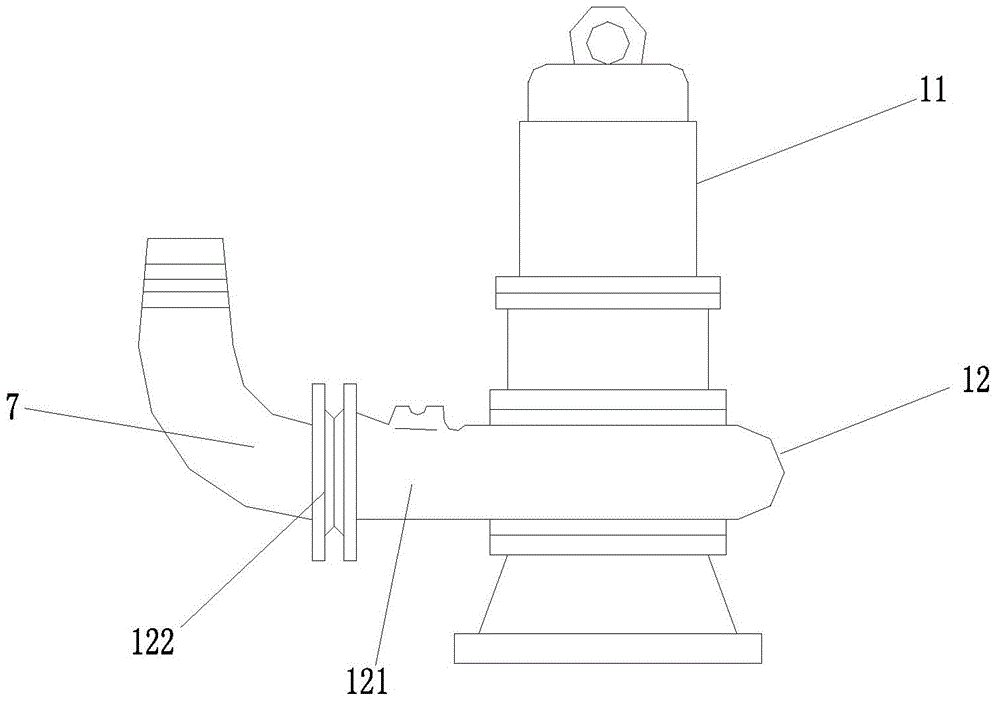

[0023] Such as figure 1 As shown, the automatic cleaning device of the present invention mainly includes a submersible pump 1, a pipeline 2, a nozzle 3 and an electric control cabinet 4. The pump 1 is electrically connected with the electric control cabinet 4 . Wherein, pipeline 2 comprises a main pipeline 21 and several outlet pipelines 22, and several outlet pipelines 22 are all connected with main pipeline 21, and the water outlet of submersible pump 1 is connected with main pipeline 21, and nozzle 3 is connected with outlet pipeline 22 one by one. Each outlet pipe 22 is provided with a valve 3, preferably, a solenoid valve, and the electric control cabinet 4 is electrically connected to the solenoid valve. A movable joint 6 is provided on the outlet pipe 22 between the valve 3 and the nozzle 3, preferably, a universal movable joint is used to facilitate adjustment of the position and angle of the nozzle 3. Preferably, the main pipeline 21 is also provided with a movable ...

Embodiment 2

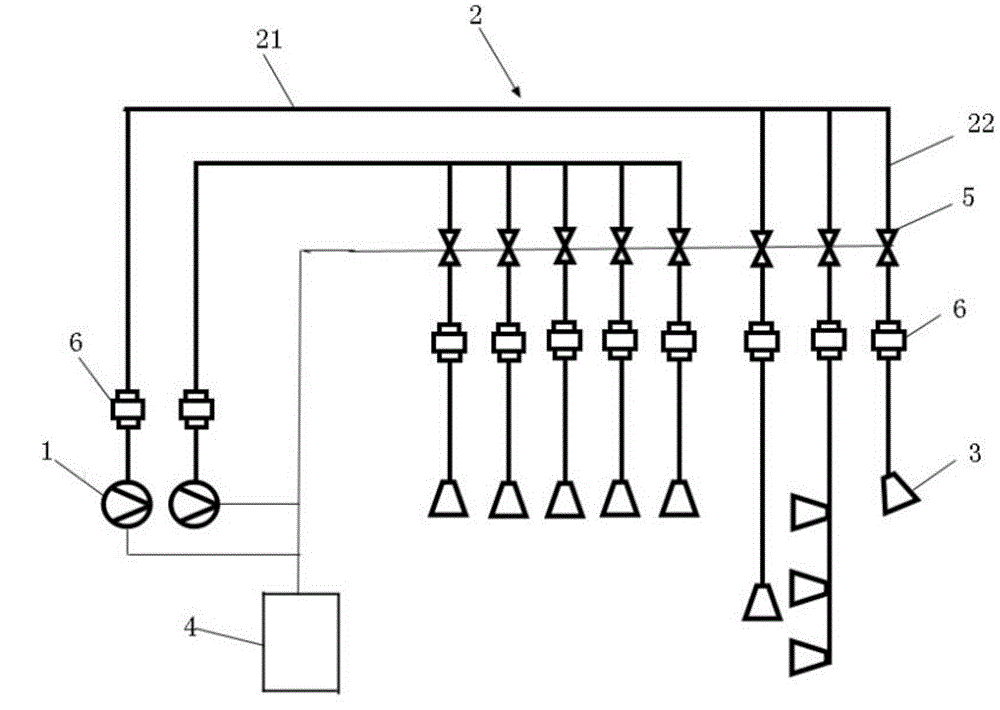

[0027] Considering the power and current of the submersible pump 1, there are two groups of pipelines 2, each group of pipelines includes a main pipeline 21 and several outlet pipelines 22, and several outlet pipelines 22 are connected with the main pipeline 21, and the outlet of the submersible pump 1 is connected to The main pipeline 21, the spray head 3 and the water outlet pipeline 22 are connected in one-to-one correspondence. Other structures are the same as in Embodiment 1.

[0028] According to needs, components such as the submersible pump 1 and the pipeline 2 can be arranged in multiple groups in the manner of the second embodiment.

[0029] The invention manufactures equipment according to the size of the water outlet tank of the secondary settling tank, and is installed on the frame of the scraping and suction dredge around the secondary settling tank, and is cleaned along with the operation of the machine. When working, first open the valve 5, set the working tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com