Ethylene-trifluorochloroethylene copolymer with novel structure, and preparation method and application thereof

A technology of chlorotrifluoroethylene and a new structure, which is applied in the field of fluorine-containing polymer materials and can solve the problems of changing the temperature resistance of resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

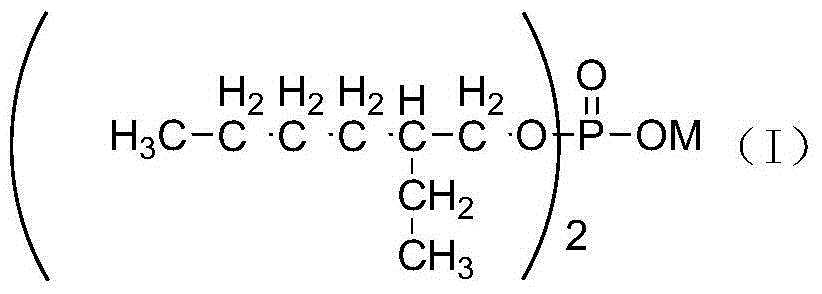

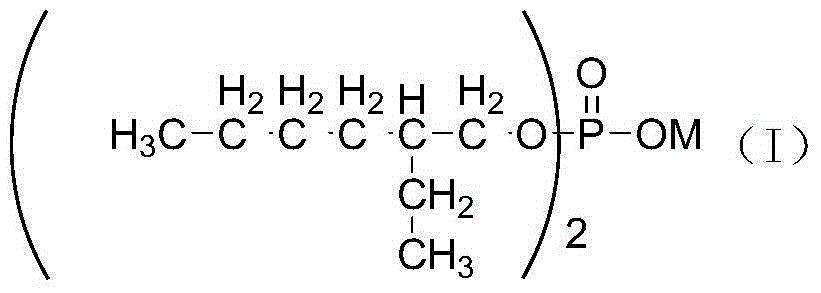

[0044] Embodiment 1: suspension polymerization method, two-(2-ethylhexyl) ammonium phosphate is surfactant

[0045] Clean the 10L stainless steel high-pressure reactor equipped with mechanical stirring, temperature control device, circulating heating and circulating cooling water, add 6L high-purity deionized water, vacuumize and replace with nitrogen three times, measure the oxygen content below 10ppm, and continue to vacuumize Until the pressure inside the reactor is -0.1MPa. Add 5.5g di-(2-ethylhexyl) ammonium phosphate, 10ml chloroform in the reactor, add 2330g chlorotrifluoroethylene, 375g hexafluoropropylene and 320g cyclohexyl vinyl ether in the reactor by metering device, stir And raise the temperature to 65°C. After the temperature of the system is constant, add ethylene into the reactor with a compressor until the pressure is 3.5MPa, and add 200ml of aqueous solution containing 2.5g of potassium persulfate into the reactor with a metering pump to initiate the polymer...

Embodiment 2

[0048] Embodiment 2: Suspension polymerization method, two-(2-ethylhexyl) phosphate potassium salt is surfactant

[0049] Clean the 10L stainless steel high-pressure reactor equipped with mechanical stirring, temperature control device, circulating heating and circulating cooling water, add 6L high-purity deionized water, vacuumize and replace with nitrogen three times, measure the oxygen content below 10ppm, and continue to vacuumize Until the pressure in the reactor is -0.1MPa, add 6.5g of di-(2-ethylhexyl) phosphate potassium salt, 15ml of methylcyclopentane into the reactor, and add 2330g of trifluorochlorine to the reactor through a metering device Ethylene, 305g hexafluoropropylene and 220g cyclohexyl vinyl ether, stir and heat up to 60°C. After the system temperature is constant, add ethylene into the reactor with a compressor until the pressure is 2.8MPa, and then add it into the reactor with a metering pump. 200ml contains 2.35g ammonium persulfate aqueous solution to...

Embodiment 3

[0052] Embodiment 3: Suspension polymerization method, two-(2-ethylhexyl) phosphoric acid ester sodium salt is surfactant

[0053]Clean the 10L stainless steel high-pressure reactor equipped with mechanical stirring, temperature control device, circulating heating and circulating cooling water, add 5.5L high-purity deionized water, vacuumize and replace with nitrogen for three times, measure the oxygen content below 10ppm, and continue pumping Vacuum until the pressure in the reactor is -0.1MPa, add 3.2g of bis-(2-ethylhexyl)phosphate sodium salt, 5ml of chloroform, and 5ml of methylcyclopentane into the reactor, and add 2330g of chlorotrifluoroethylene, 450g of hexafluoropropylene and 400g of cyclohexyl vinyl ether, add 700ml of aqueous solution containing 7.5g of potassium persulfate to the reactor with a metering pump, stir and raise the temperature to 35°C. Add ethylene into the reactor until the pressure is 1.65MPa, add 100ml of aqueous solution containing 1.5g of sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com