Preparation method for carboxymethyl cellulose nitrate resin water-borne dispersoid

A technology of carboxymethyl cellulose and water-based dispersion, applied in the direction of coating, etc., can solve problems such as damage, excessive use of benzene solvents, environmental and human health pollution, etc., and achieve good film-forming performance, high industrial production capacity, Pollution and damage reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific embodiments. The described embodiments are only preferred embodiments of the present invention, and are not intended to limit the present invention. For those skilled in the art, the present invention may have various modifications and changes. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

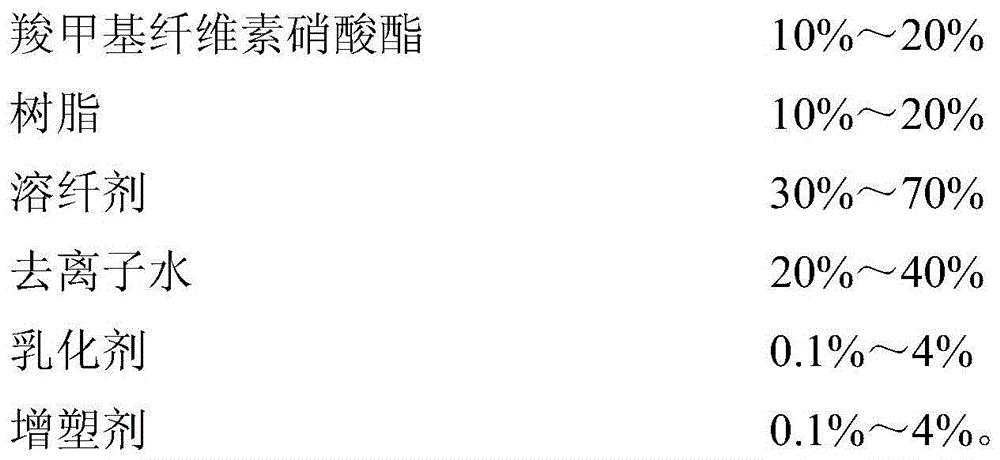

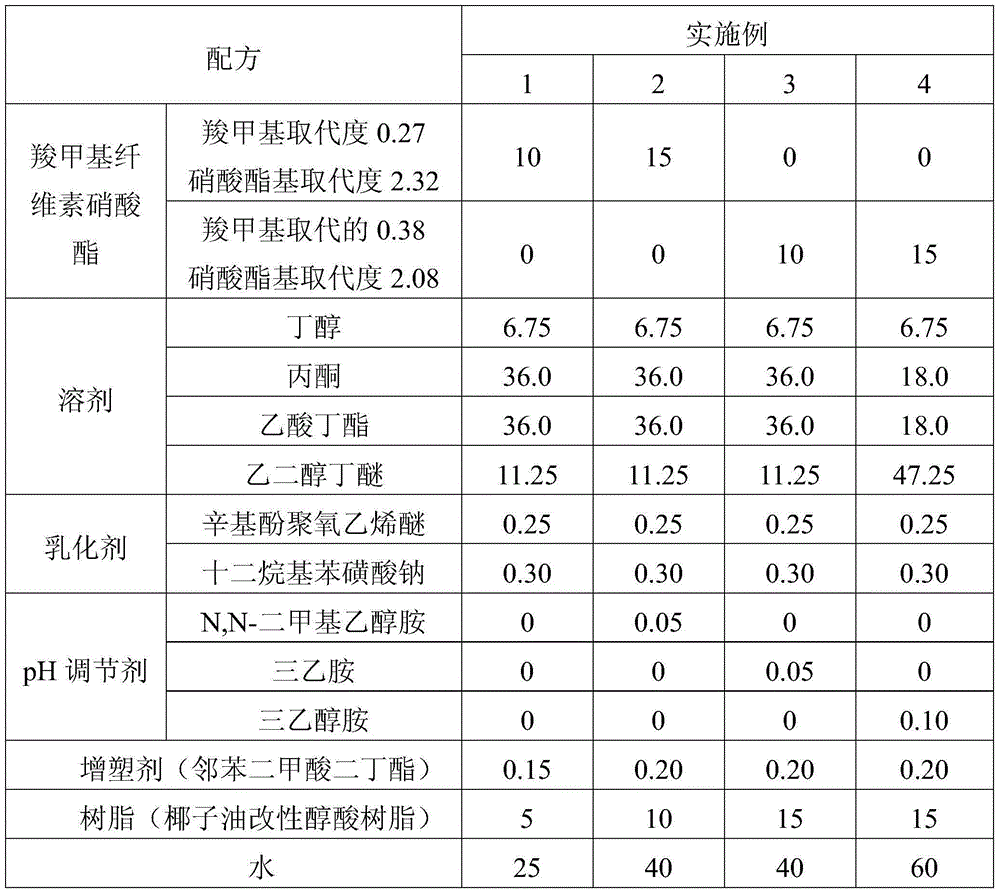

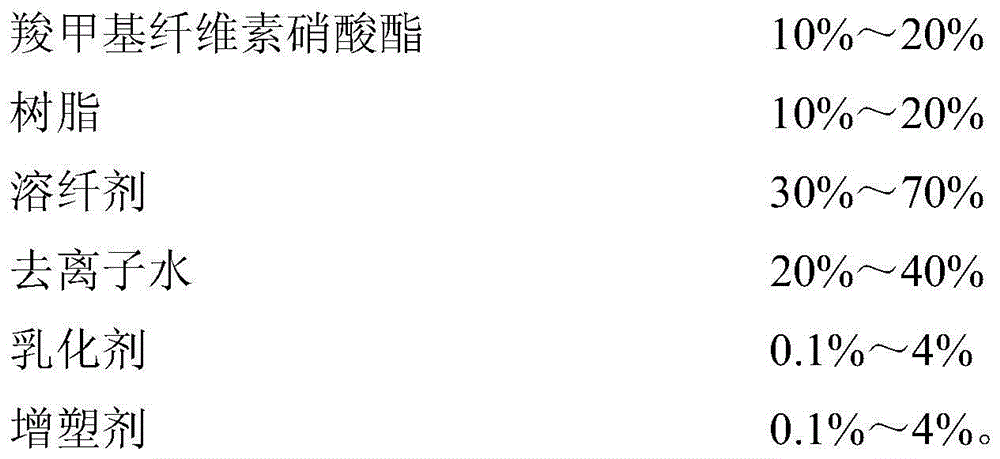

[0052] What table 1 lists is the preparation formula embodiment of carboxymethyl cellulose nitrate resin aqueous dispersion, and table 2 is the performance index of all carboxymethyl cellulose nitrate resin aqueous dispersions corresponding to table 1.

[0053] The preparation method of listed carboxymethyl cellulose nitrate resin aqueous dispersion in table 1 is:

[0054] (1) Add a certain proportion of cellosolve in the container, slowly add carboxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com