High-luster halogen-free flame-retardation antibiosis PP material and manufacture method thereof

A high-gloss, flame retardant technology, applied in the field of flame retardant materials, can solve the problems of large addition amount and reduce the mechanical properties of PP, and achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

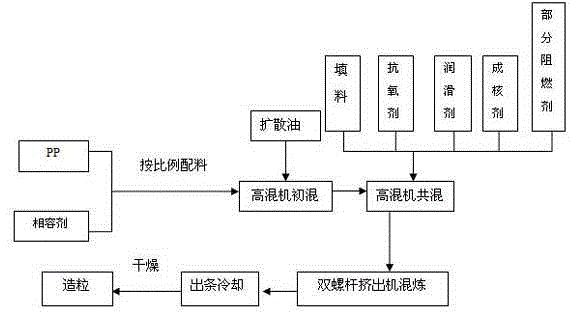

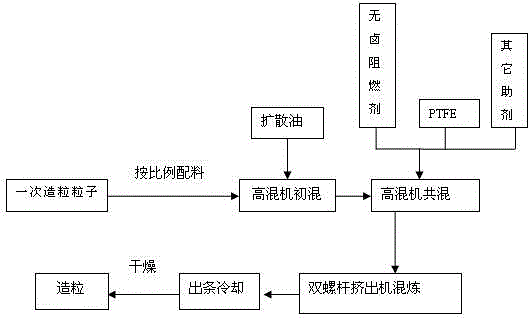

[0039] The preparation method of the high-gloss halogen-free flame-retardant antibacterial PP material of the present invention comprises the following two steps:

[0040] (1) One-step granulation: such as figure 1 As shown, add PP and compatibilizer into the high-speed mixer in proportion, add diffusion oil for preliminary mixing, and then add mineral fillers, antioxidants, lubricants, nucleating agents and part of flame retardants in proportion to The high-speed mixer is used for mixing, and after mixing evenly, it is transported to the twin-screw extruder for mixing. The part of the flame retardant refers to 30%-40% of the total mass of the flame retardant. The aspect ratio of the twin-screw extruder is 40:1, and the temperature of each temperature zone of the extruder is one stage: 180-195°C; two stage: 195-205°C; three stage: 195-205°C; four stage: 205-215°C; 5th stage: 205-220°C; 6th stage: 210-220°C; 7th stage: 205-210°C; head 190-205°C. The extruded material is cool...

Embodiment 1-5

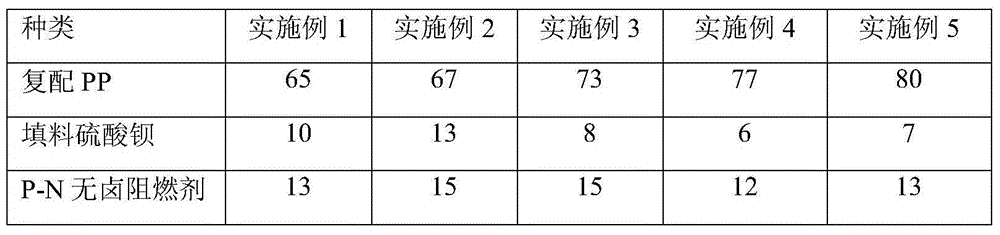

[0045] The high-gloss halogen-free flame-retardant antibacterial PP material of the present invention was prepared according to the component formula shown in Table 1, and the performance test of the prepared material was performed, and the results are shown in Table 2.

[0046] Table 1 prepares the component formula of the high-gloss halogen-free flame-retardant antibacterial PP material of the present invention

[0047]

[0048]

[0049] Table 2 The performance test results of the high-gloss halogen-free flame-retardant antibacterial PP material prepared by the present invention

[0050]

[0051] Relevant test methods and standards:

[0052] 1. GB / T1033: Melt flow rate, "Test method for tensile properties of plastics".

[0053] 2. GB / T1040-1992: National Standard for Tensile Strength Test, "Test Method for Tensile Properties of Plastics".

[0054] 3. GB / T9341-2000: National Standard for Bending Strength Test, "Test Method for Bending Properties of Plastics".

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com