Coal gas combined purification tower

A technology for purifying towers and gas, applied in combustible gas purification, combustible gas purification/transformation, removal of gas pollutants, etc. Troubleshooting problems such as cumbersome operation, to achieve the effect of reducing the number of equipment and floor area, improving the service life and improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

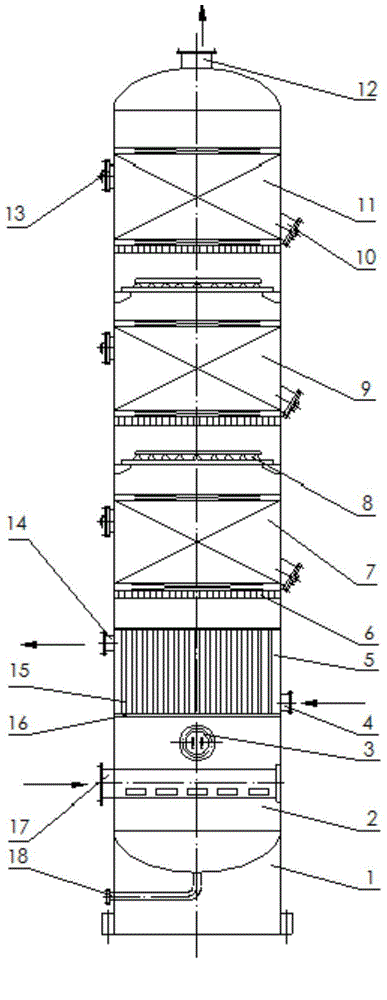

[0015] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0016] Such as figure 1 As shown, the vertical tower includes a gas cooling section (5), a tar removal section (7), a desulfurization section (9) and a naphthalene removal section (11) sequentially from bottom to top, and the sections are connected in series. Gas inlet pipe (17) and blowdown outlet (18) are installed in tower body (2) bottom, and the bottom of gas inlet pipe is evenly distributed some exhaust outlets, and manhole (3) is set above gas inlet pipe (17), and manhole (3 ) is provided with a gas cooling section (5).

[0017] The gas cooling section (5) includes fixed tube sheets (16), heat exchange tubes (15), cooling water inlets (4) and cooling water outlets (14), the tube side medium is gas, and the shell side medium is cooling water. A tar removal section (7) is arranged above the gas cooling section (5).

[0018] The detarring sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com