Anti-scaling evaporation cooling equipment for coal gas dry dedusting of converter

A dry dust removal and evaporative cooling technology, applied in the manufacture of converters, etc., can solve the problems of substandard dust emission, easy ash clogging, pollution of the environment, etc., to reduce equipment failure rate, ensure normal production, and solve the effect of site restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

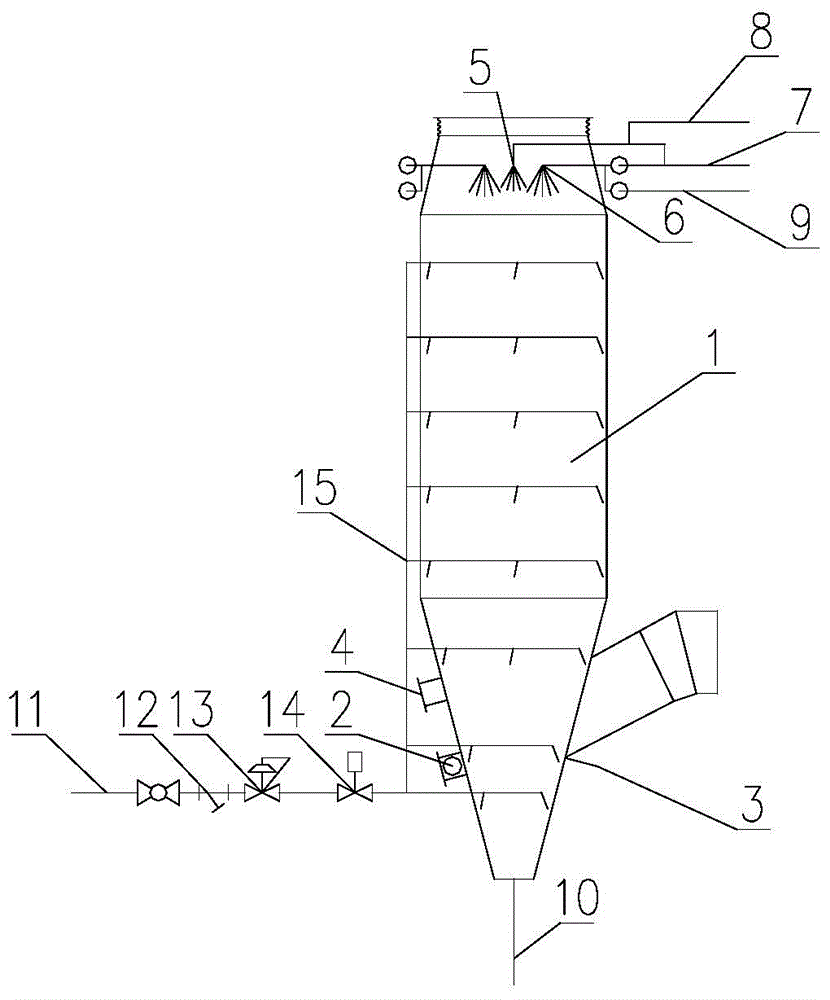

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0020] like figure 1 As shown, the converter gas dry dust removal and anti-scaling evaporative cooling equipment of the present invention includes an anti-scaling evaporative cooler 1, a rapping device 2, a dual-medium conditioning spray gun 5, a dual-medium cooling spray gun 6 and a blowing and cleaning device 15 ;

[0021] The anti-scaling evaporative cooler 1 entrance is equipped with a high-temperature resistant non-metallic compensator for compensating for thermal expansion and contraction of the equipment; the outlet of the lower cone bucket is connected to the ash discharge main pipe 10, and the coarse ash collected by the lower cone bucket falls into the coarse ash under the action of gravity warehouse; the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com