High temperature infiltration nitrogen treatment method of stainless steel sieve plate

A stainless steel sieve, stainless steel technology, applied in the direction of coating, metal material coating process, solid diffusion coating, etc., can solve the problems of corrosion and wear of sieve plate, and achieve the effect of prolonging service life, simple process and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Surface Pretreatment

[0032] The surface of the stainless steel sieve plate is treated with a general electroless Ni plating pretreatment method, which is divided into two steps of cleaning and activation: first use alcohol or gasoline to completely remove the oil on the surface of the workpiece, and then pickle the surface to remove the oxide film on the surface of the workpiece, acid Washing temperature: 15-30°C, pickling time: 3-5min;

[0033] Step 2: Electroless Nickel Flash Plating

[0034] Immediately after pickling to remove the oxide film on the surface of the stainless steel sieve plate, immerse it in the flash nickel solution. When performing nickel flash plating, the stainless steel sieve plate should be pre-soaked in the plating tank for 10-15 minutes before being energized. After electrification, the plated parts stay in the plating tank for 3 minutes, and after nickel flash plating, they must be quickly put into the nitriding furnace after clean...

Embodiment 2

[0039] In addition to the second step of electrification, the plated parts stay in the plating tank for 5 minutes, and in the third step of high temperature dissolved nitrogen treatment, the dissolved nitrogen temperature is set to 1050 ° C, the pressure in the furnace is set to 2 bar, and the nitriding time is kept for 4 hours. Except for the parameter changes in the above two steps, all other processes and parameters are the same as in the first embodiment.

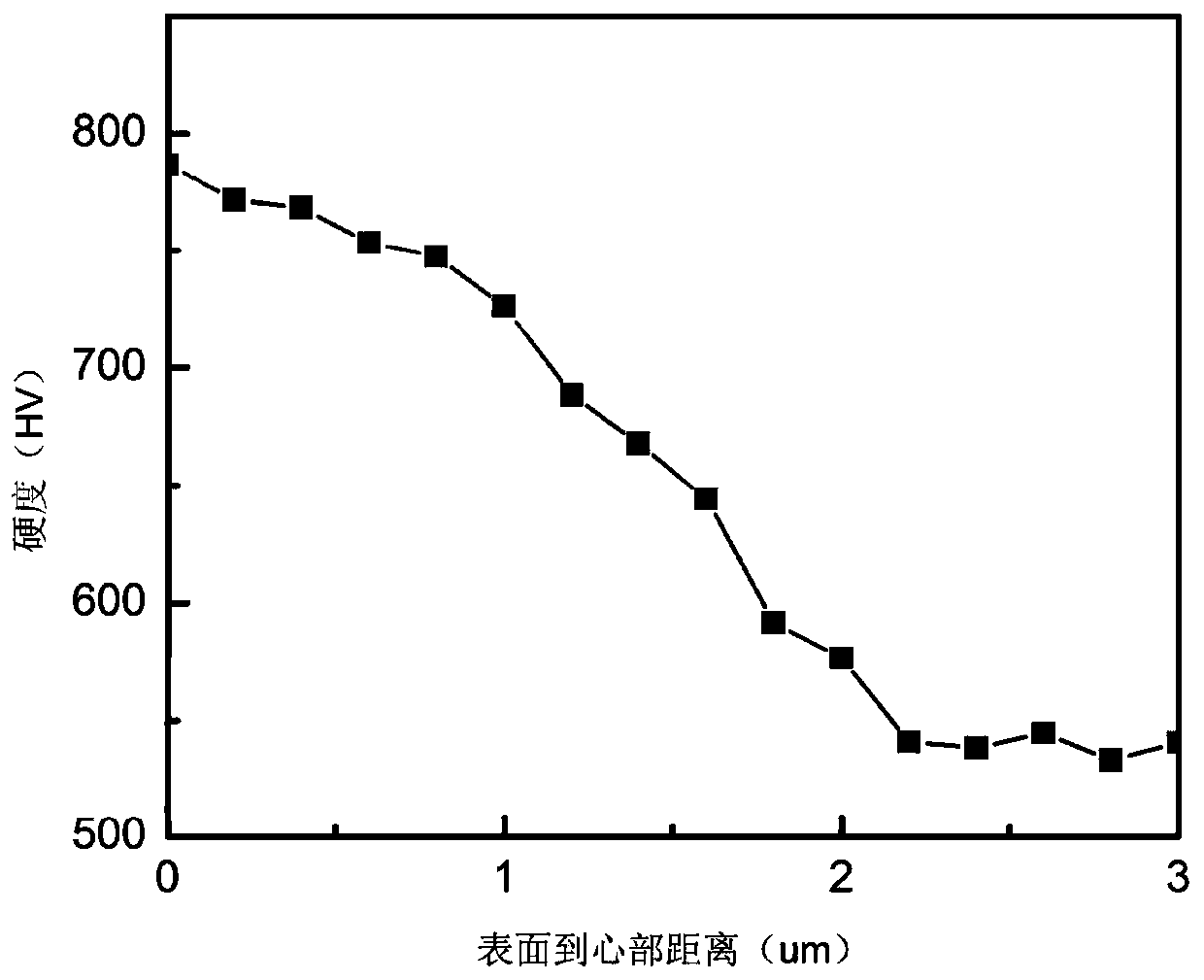

[0040] It has been tested: the martensite depth of the solid-dissolved nitrogen obtained in Example 2 reaches 1 mm, and the hardness can be increased by 1.3 times.

Embodiment 3

[0042] In addition to the second step of electrification, the plated parts stay in the plating tank for 4 minutes, and in the third step of high temperature dissolved nitrogen treatment, the dissolved nitrogen temperature is set to 1010 ° C, the pressure in the furnace is set to 1.5 bar, and the nitriding time is kept for 3 hours. Except for the parameter changes in the above two steps, all other processes and parameters are the same as in the first embodiment.

[0043] It has been tested: the martensite depth of solid-dissolved nitrogen finally obtained in Example 3 reaches 1.5 mm, and the hardness can be increased by 1.5 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com