Noise barrier

A sound barrier and wall panel technology, applied in the field of traffic noise control equipment, can solve the problems of reducing the sound absorption process of closed holes and weakening the sound absorption function, and achieve the ideal effect of noise elimination, sound insulation or sound absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

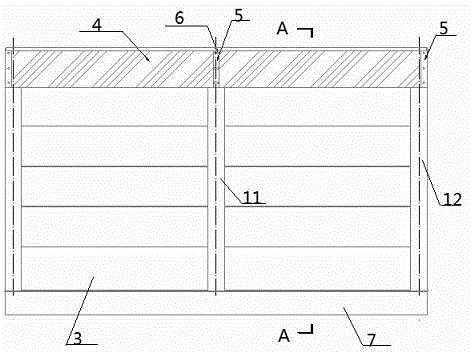

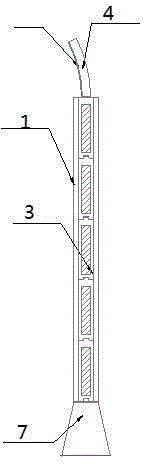

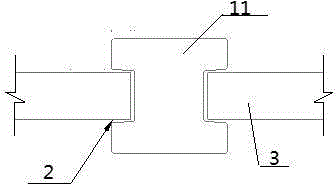

[0082] Such as figure 1 , a sound barrier, comprising a plurality of columns 1 and a plurality of wall panels 3 connected up and down between adjacent columns 1, the top wall panels 3 are provided with arc-shaped panels 4, and the wall panels 3 A sound-absorbing panel is arranged between the two sound-insulating panels.

[0083] The sound insulation board is cast from ultra-high performance powder concrete. The sound-absorbing board is made of vitrified microbead foamed concrete.

[0084] The thickness of the sound insulation board is 20mm.

[0085] The thickness of the sound-absorbing board is 80mm.

[0086] Such as figure 1 , the arc-shaped plate 4 is a sound reflection area, and the arc-shaped plate 4 is a plurality of pieces, T-shaped steel 5 is arranged between two adjacent arc-shaped plates, and a plurality of bolt holes are arranged on the T-shaped steel 5, and the arc-shaped plate 4 Horizontally side by side and fixedly connected by bolts 6, as shown in the figure...

Embodiment 2

[0127] Other conditions are the same as in Example 1, except that the sound-insulating board is made of ultra-high-performance powder concrete with the following formula, and the sound-absorbing board is cast with vitrified microbead foamed concrete with the following formula.

[0128] The sound insulation board is cast from ultra-high performance powder concrete, and the formula is as follows:

[0129] 1,200 parts of 52.5 grade Portland cement with an average particle size of 30-60 μm;

[0130] 150 parts of micro-silicon powder with an average particle size of 0.1~0.5 μm and a SiO2 content of ≥92%;

[0131] 150 parts of mineral powder with an average particle size of 10~50μm;

[0132] 100 parts of polished brick powder with an average particle size of 0.5-25 μm

[0133] 1450 parts of quartz sand with a particle size of 0.63~0.16mm;

[0134] 22 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0135] 80 parts of inorganic pigment po...

Embodiment 3

[0150] The other conditions are the same as in Example 1, except that the sound-absorbing board is made of ultra-high-performance powder concrete with the following formula, and the sound-absorbing board is cast with vitrified microbead foamed concrete with the following formula.

[0151] The sound insulation board is cast from ultra-high-performance powder concrete, and the ultra-high-performance powder concrete includes the following raw materials in parts by weight:

[0152] 1100 parts of 52.5 grade Portland cement with an average particle size of 30-60 μm;

[0153] 120 parts of micro-silicon powder with an average particle size of 0.1~0.5 μm and a SiO2 content of ≥92%;

[0154] 120 parts of mineral powder with an average particle size of 10~50μm;

[0155] 80 parts of polished brick powder with an average particle size of 0.5-25 μm

[0156] 1250 parts of quartz sand with a particle size of 0.63~0.16mm;

[0157] 20 parts of high-efficiency water reducing agent with water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com