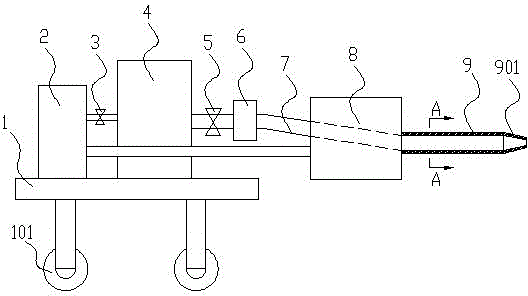

Safe, efficient and environment-friendly rock blasting device and blasting method

A rock blasting and high-efficiency technology, applied in the field of rock blasting, can solve the problems of reducing explosive force, labor and material costs, safety accidents, etc., and achieve the effects of reducing efficiency, eliminating pollution, and facilitating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A safe, efficient and environment-friendly rock blasting method, which comprises the following steps:

[0046] 1) Determine the position and angle of the blast hole. According to the specific conditions of the mountain, determine the position of the blast hole at the foot of the mountain, and drill the hole with a slope of 5 degrees from bottom to top;

[0047] 2) Drilling and blasting holes, using a drilling device to drill holes, and the depth of the drilling holes is determined according to the mountain;

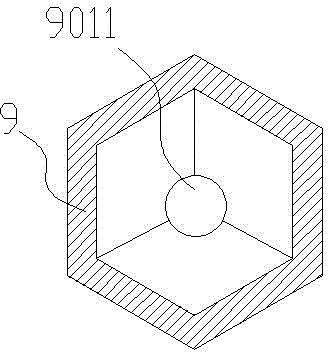

[0048] 3) To expand the hole, first put 200 grams of explosives and a detonator in the deepest part of the blasting hole to detonate according to the depth of the blasting hole. , and then scraped out the blasted rock slag, so many explosions, the deepest part of the blast hole will be exploded bigger and bigger, forming a bird's nest shape;

[0049] 4) For blasting, weigh an appropriate amount of explosives according to the size of the mountain and the blast hole...

Embodiment 2

[0051] A safe, efficient and environment-friendly rock blasting method, which comprises the following steps:

[0052] 1) Determine the position and angle of the blast hole. According to the specific conditions of the mountain, determine the position of the blast hole at the foot of the mountain, and drill the hole with a slope of 10 degrees from bottom to top;

[0053] 2) Drilling and blasting holes, using a drilling device to drill holes, and the depth of the drilling holes is determined according to the mountain;

[0054] 3) To expand the hole, first put 250 grams of explosives and a detonator in the deepest part of the blasting hole to detonate according to the depth of the blasting hole. , and then scraped out the blasted rock slag, so many explosions, the deepest part of the blast hole will be exploded bigger and bigger, forming a bird's nest shape;

[0055] 4) For blasting, weigh an appropriate amount of explosives according to the size of the mountain and the blast hol...

Embodiment 3

[0057] A safe, efficient and environment-friendly rock blasting method, which comprises the following steps:

[0058] 1) Determine the position and angle of the blast hole. According to the specific conditions of the mountain, determine the position of the blast hole at the foot of the mountain, and drill the hole with a slope of 15 degrees from bottom to top;

[0059] 2) Drilling and blasting holes, using a drilling device to drill holes, and the depth of the drilling holes is determined according to the mountain;

[0060] 3) For hole reaming, first put 300 grams of explosives and a detonator in the deepest part of the blasting hole according to the depth of the blasting hole to detonate, remove the debris after detonation, and then put about 570 grams of explosives and a detonator into the deepest part of the blasting hole to detonate , and then scraped out the blasted rock slag, so many explosions, the deepest part of the blast hole will be exploded bigger and bigger, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com