A method for determining the effective components of desulfurized quicklime

A technology of active ingredients and quicklime, which is applied in the direction of removing certain components such as weighing, measuring devices, and analyzing materials, which can solve the problems of large error in test results, large human errors, and large errors, and achieve accurate and reliable results. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

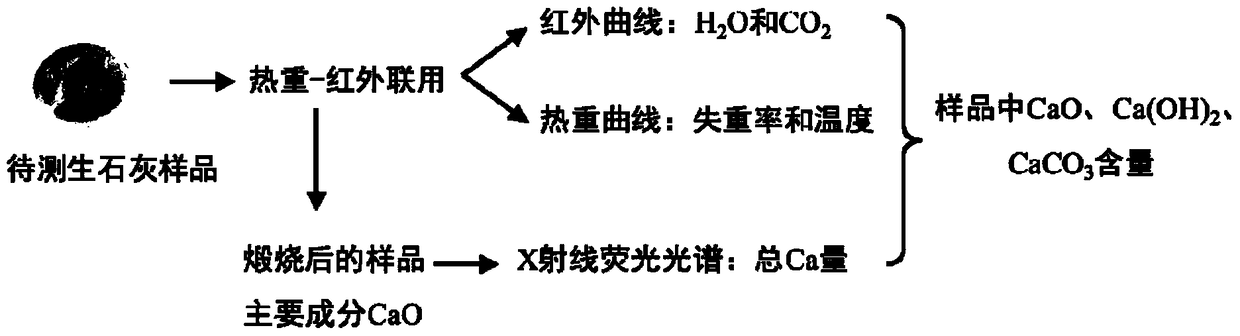

[0042] In this embodiment, the method for determining the effective components of desulfurized quicklime is determined by the following method, which specifically includes the following steps (the method flow is as follows: figure 1 shown):

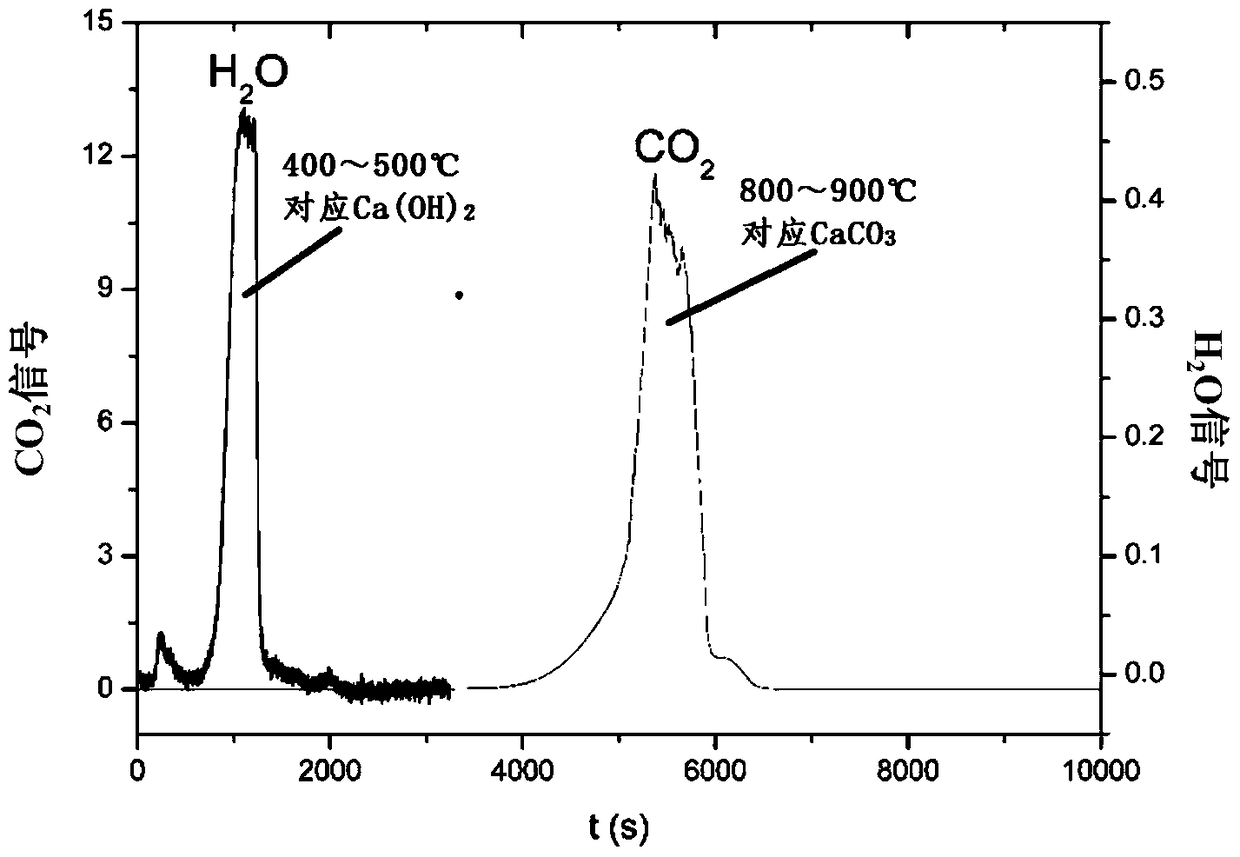

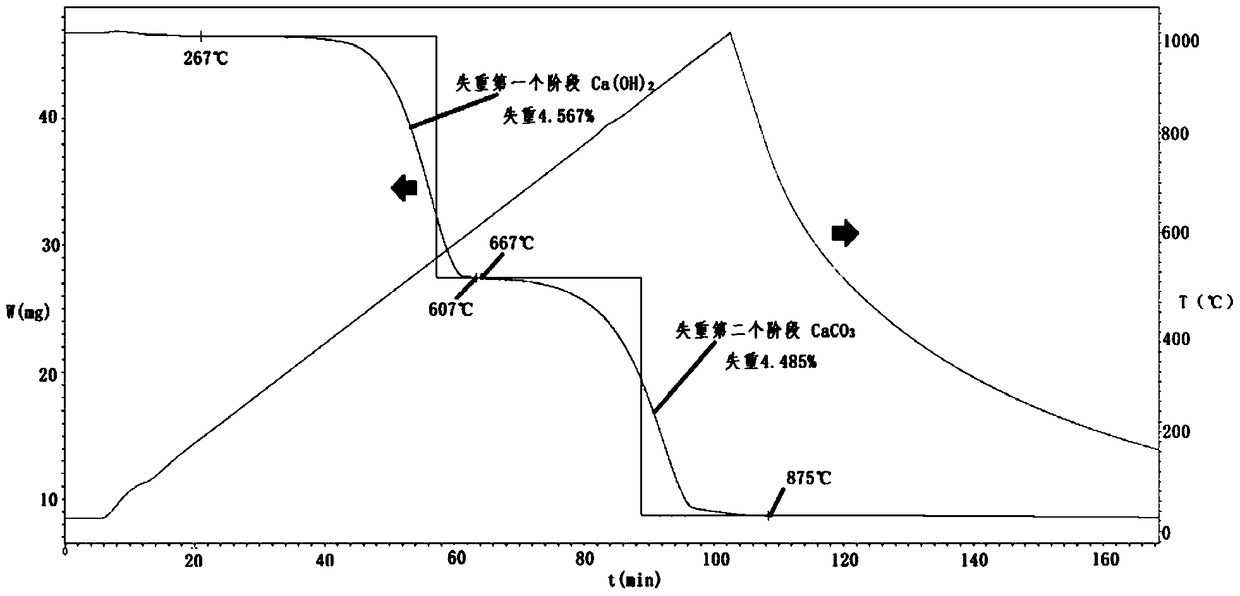

[0043] (1) Put 100 mg of the dried desulfurized quicklime sample into a thermogravimetric analyzer for thermogravimetric measurement. During the thermogravimetric measurement, the heating rate is 10°C / min, and the temperature is raised from room temperature to 1100°C. Analyze the decomposition products. Such as figure 2 As shown, only H was detected in the infrared curve of the desulfurized quicklime decomposition sample 2 O and CO 2 , corresponding to image 3 The thermogravimetric temperature in the thermogravimetric curve shown is between 267-607°C and 667-875°C. The analysis shows that the product decomposed in the first weightloss stage is H 2 O, the weight loss percentage is 4.567% (x H2O ), according to the decomposition tem...

Embodiment 2

[0056] The difference between this example and Example 1 is that the amount of desulfurized quicklime sample is 50 mg and put into a thermogravimetric analyzer for thermogravimetric measurement. During the thermogravimetric measurement, the heating rate is 5°C / min, from room temperature to 900°C The same method as in Example 1 was used to measure the effective components and content of the desulfurized quicklime sample, and only H was detected in the infrared curve of the desulfurized quicklime sample. 2 O and CO 2 , the temperature ranges corresponding to the first and second weight loss stages in the thermogravimetric curve are 302-634°C and 673-882°C respectively, the weight loss percentage in the first weight loss stage is 4.893%, and the weight loss percentage in the second weight loss stage is 4.673%; Contain elements such as Ca, Mg, Si, O in the X-ray fluorescence spectrometer measurement undecomposed sample, their mass percentages are respectively 70.41%, 1.86%, 1.02%,...

Embodiment 3

[0058] The difference between this example and Example 1 is that the amount of desulfurized quicklime sample is 50 mg and put into a thermogravimetric analyzer for thermogravimetric measurement. During the thermogravimetric measurement, the heating rate is 10°C / min, from room temperature to 980°C The content of active ingredient in the desulfurized quicklime sample is obtained after the same method of embodiment 1 is measured, and only H is detected in the infrared curve of the desulfurized quicklime decomposed sample. 2 O and CO 2 , the temperature ranges corresponding to the first and second weight loss stages in the thermogravimetric curve are 268-613°C and 672-882°C respectively, the weight loss percentage in the first weight loss stage is 4.582%, and the weight loss percentage in the second weight loss stage is 4.621% ; The X-ray fluorescence spectrometer determined that the undecomposed sample contained Ca, Mg, Si, O and other elements, and their mass percentages were 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com