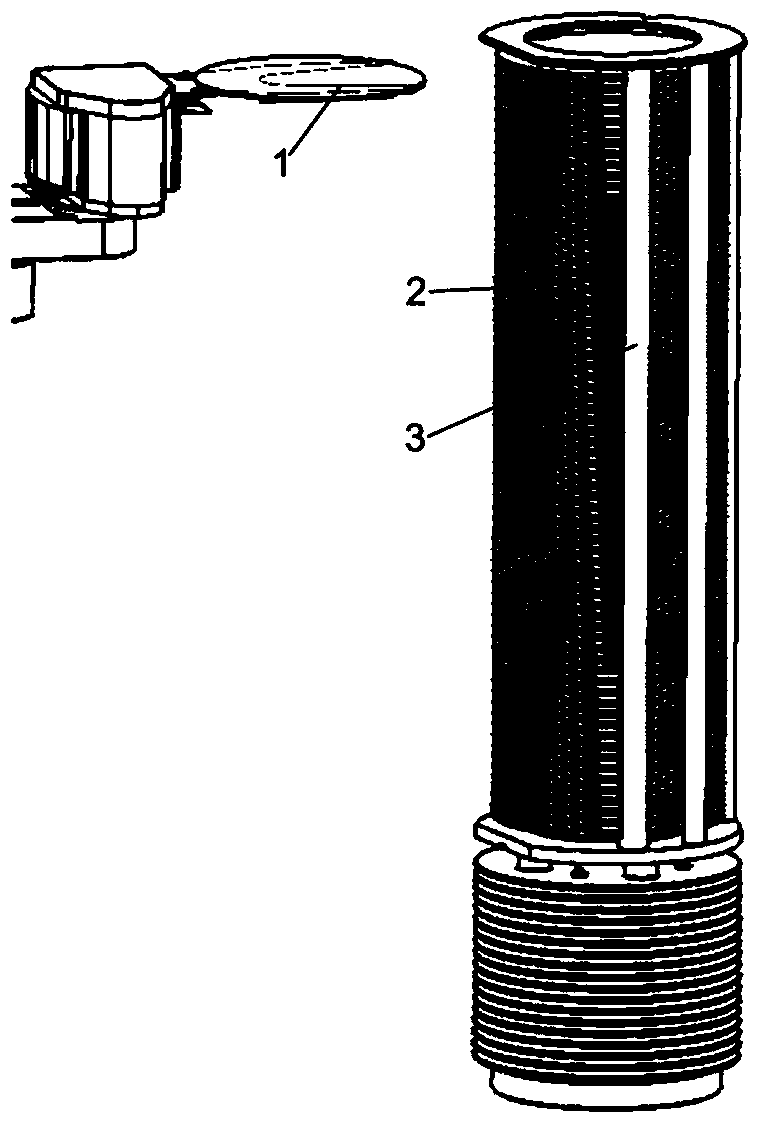

Method and device for image detection of silicon wafer distribution state in semiconductor equipment carrying area

A technology of equipment carrying and distribution status, applied in image enhancement, image analysis, image data processing, etc., can solve problems such as damage to silicon wafers or equipment, collisions, missed reports, etc., to avoid damage to silicon wafers and equipment, and improve detection. Precision, good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0162] In this embodiment, two photoelectric sensors / or ultrasonic sensor solutions on the machine are adopted; the implementation of step S3 in this kind of solution may specifically include the following steps (taking photoelectric sensors 4 and 5 as examples):

[0163] Step S31: According to the thickness of the silicon wafer and the distance between adjacent silicon wafers, obtain the motion scanning area for judging the oblique slice, laminated slice and empty slice;

[0164] Step S32: Manipulator 1 is positioned at the position of the end point of the horizontal movement and the position of the vertical start point;

[0165] Step S33: According to the preset detection area where the two photoelectric sensors 4, 5 transmit and receive light signals and the light signal shielding width in this area, sequentially determine whether there are oblique slices, stacked slices and / or the corresponding silicon wafer placement positions Or the abnormal state of empty sheet; If yes,...

Embodiment 2

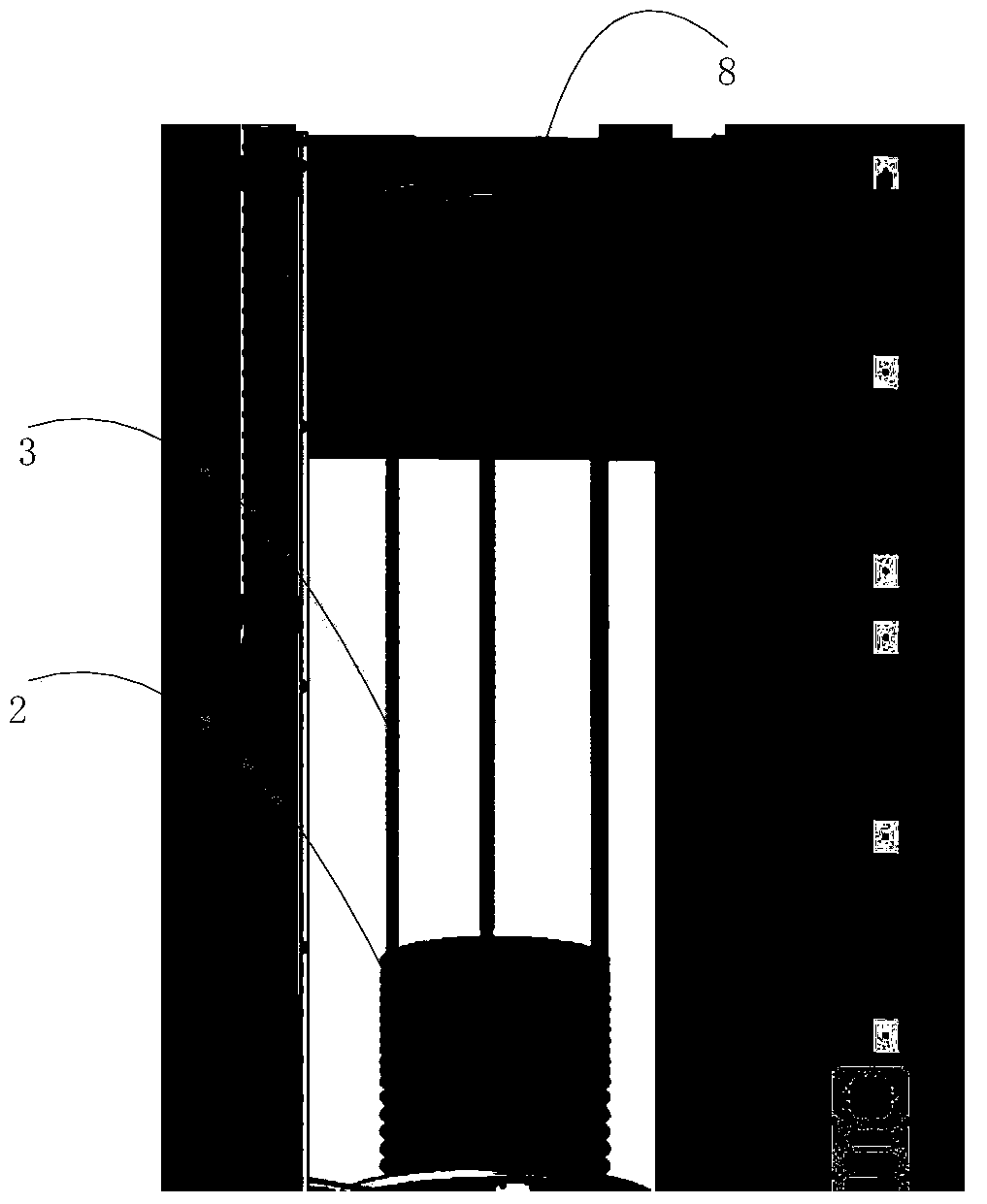

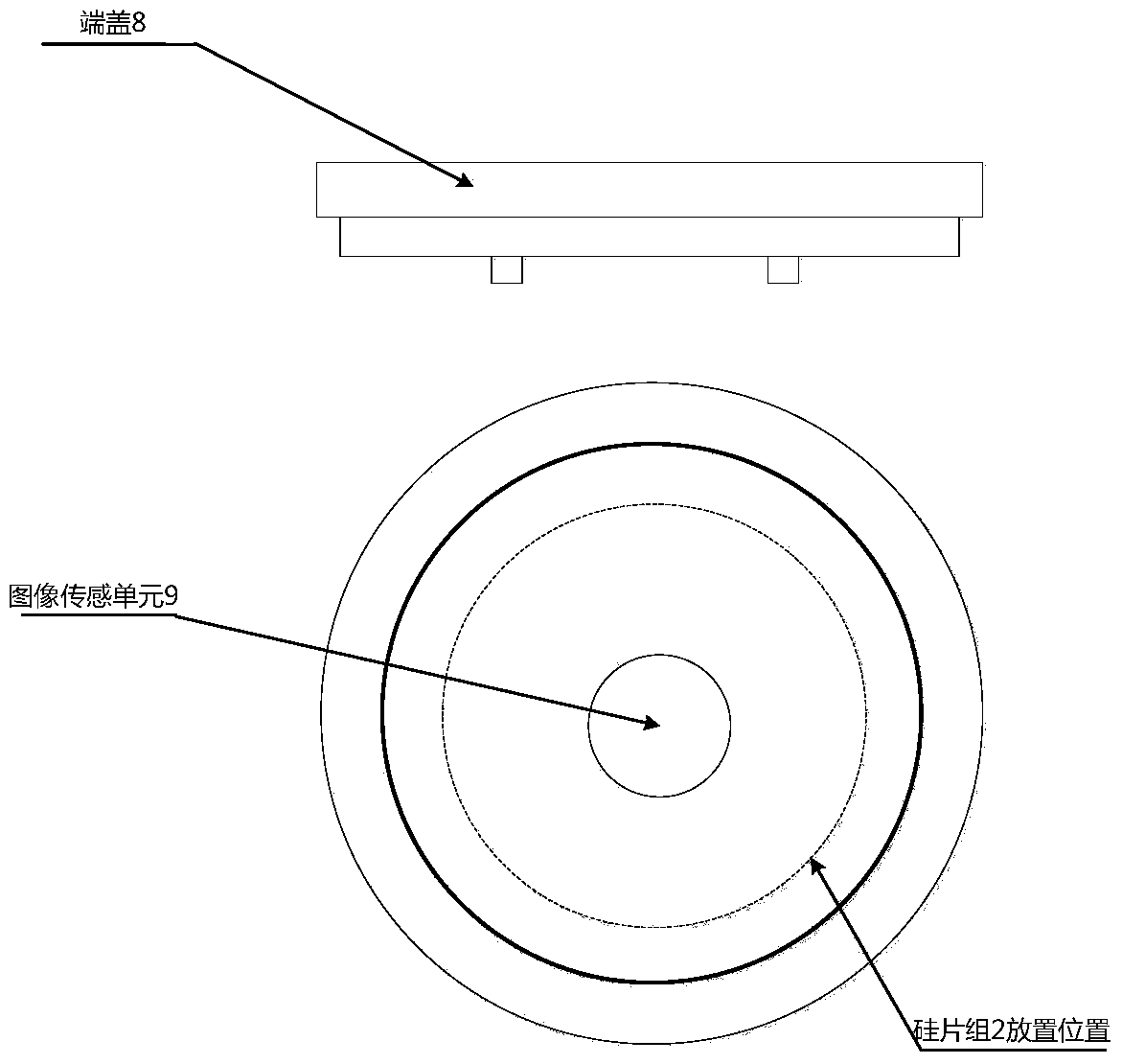

[0189] In the embodiment of the present invention, if the image sensing unit in the image detection device for the distribution state of the silicon wafer in the semiconductor equipment carrying area is located on the manipulator, then, in the embodiment of the present invention, the image sensing unit is used in the The scheme of collecting the side graphics of each silicon wafer in the silicon wafer group 2 can also be used to determine whether there is an abnormal state of oblique wafers, stacked wafers and / or empty wafers. The implementation of step S3 of the scheme can specifically include the following steps :

[0190] Step S31': According to the thickness of the silicon wafer, the distance between adjacent silicon wafers and the thickness of the carrier, obtain the motion scanning area for judging the inclined wafer, laminated wafer and empty wafer;

[0191] Step S32': Manipulator 1 is positioned at the starting point of the horizontal motion and the vertical end point;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com