Flow battery negative electrolyte solution sealing system and flow battery system

A negative electrode electrolyte and flow battery technology, applied in fuel cells, regenerative fuel cells, sealing/supporting devices, etc., can solve the problems of carbon felt losing its electrical conductivity and catalytic function, unable to characterize, and sticking to its surface, etc., to achieve Good operation safety and stability, good fluidity and air tightness, and the effect of reducing the capacity decay speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

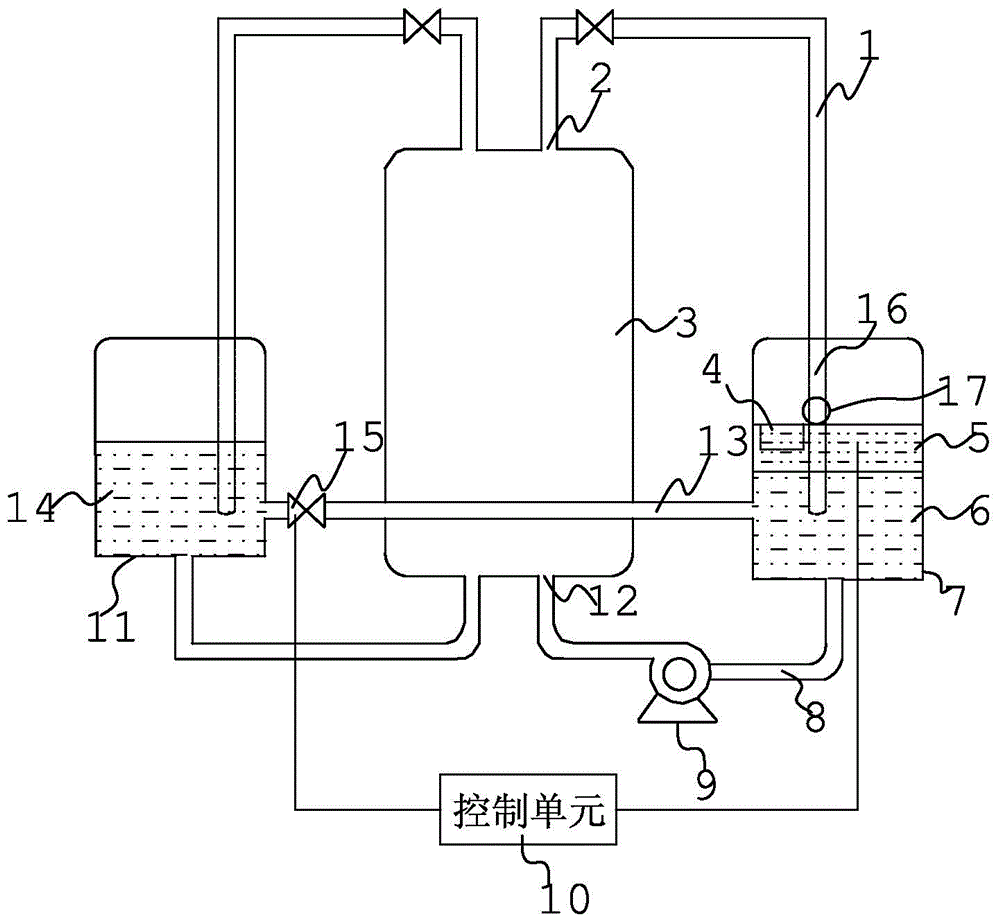

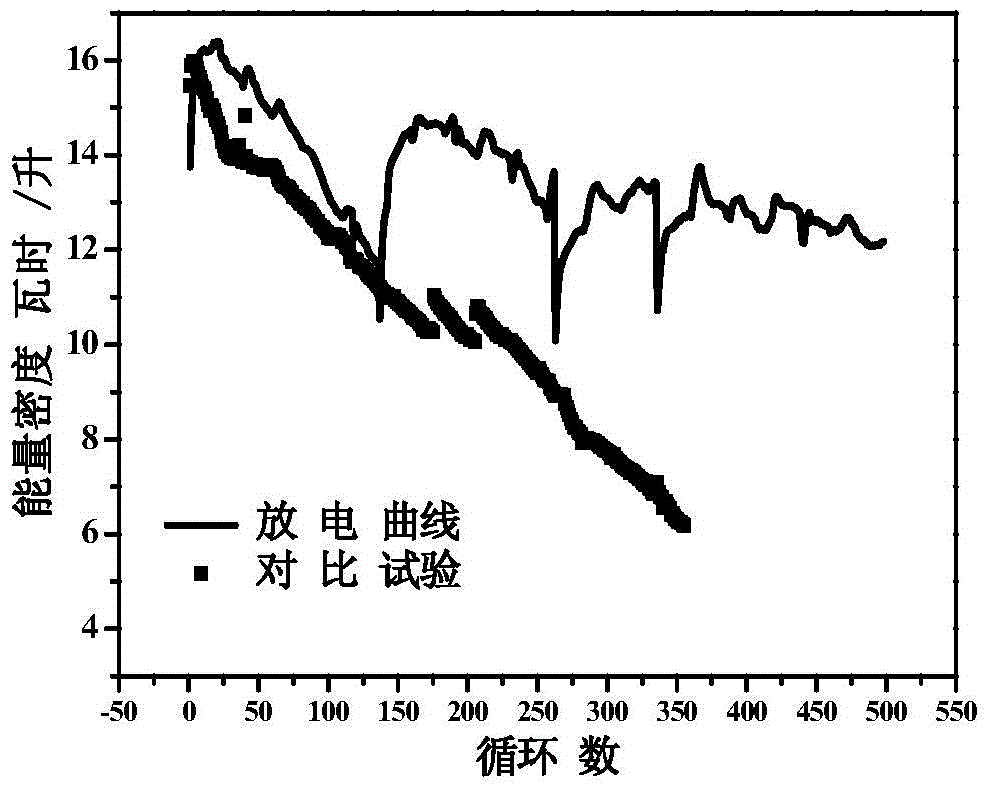

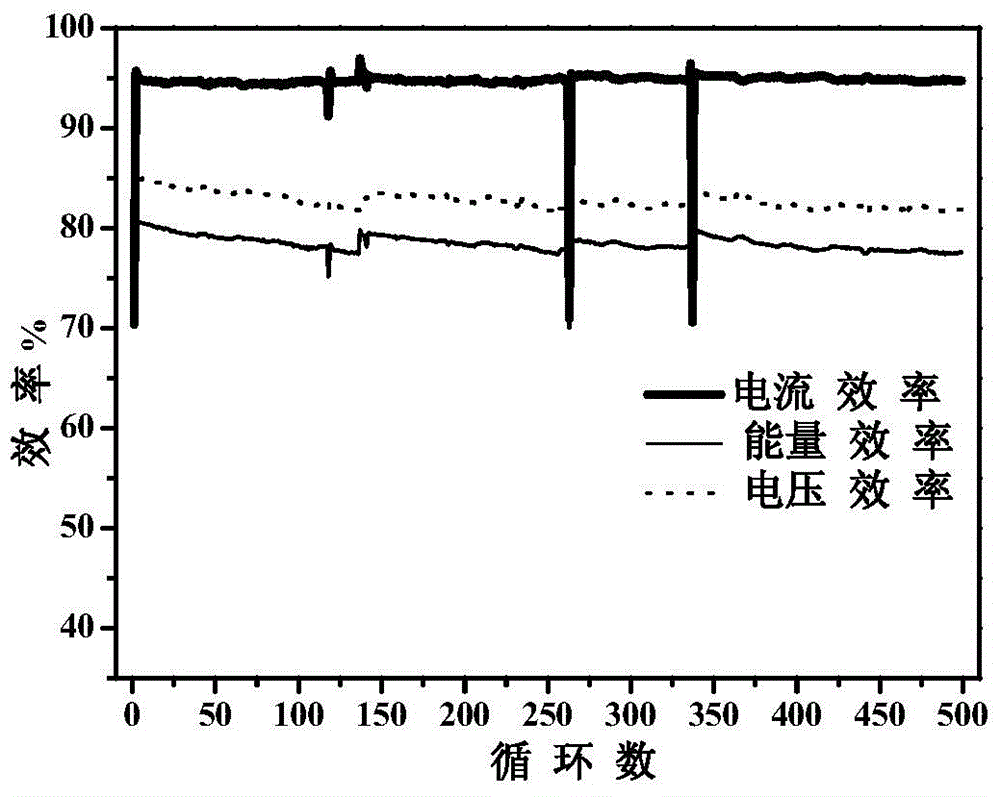

[0038] Table 1 is the test parameter table of the organic matter sealing test 1, figure 2 is the curve graph of the energy density in the organic sealing experiment 1 with the number of charge and discharge cycles, image 3 is the change curve of the efficiency in the organic matter sealing experiment 1 with the number of charge and discharge cycles, as shown in Table 1, figure 2 with image 3 As shown, the premise is to adopt the seal of the organic matter layer. The organic matter is esters, specifically vegetable oil (the main component is triglyceride), and the negative electrode electrolyte outlet of the stack is connected to the negative electrode storage tank through the first pipeline to ensure that the second The outlet of the negative electrode electrolyte of the first pipeline is always located below the liquid level of the negative electrode electrolyte, which can realize the long-term operation of the sealed system without affecting the flow battery. The flow b...

Embodiment 2

[0042] Table 2 is the test parameter list of the organic sealing experiment 2, Figure 4 is the graph of the change of energy density with the number of charge and discharge cycles in the organic matter sealing experiment 2, Figure 5 It is a curve diagram of the efficiency in the organic matter sealing experiment 2 with the number of charge and discharge cycles. Table 3 is the attenuation and efficiency data table of the organic matter sealing experiment 2, such as table 2, Figure 4 , Figure 5 As shown in Table 3, the premise is to adopt the seal of the organic matter layer. The organic matter adopts esters, specifically mineral oil. The negative electrode electrolyte outlet and the negative electrode storage tank are connected to the negative electrode storage tank and the negative electrode electrolyte inlet of the stack through the second pipeline, and the negative electrode storage tank and the positive electrode storage tank are connected through the communication pip...

Embodiment 3

[0049] Table 4 is the test parameter table of organic matter sealing experiment 3, and table 5 is the test result data table of organic matter sealing experiment 3, in order to investigate the discharge capacity retention of the flow battery system with the negative storage tank sealing system during long-term storage after full charge , as shown in Table 4 and Table 5, the organic matter is a mixture of esters and alkanes, specifically a mixture of soybean oil and dodecane. The test uses a 2kW flow battery system. After the system is charged, at this time in the negative electrode electrolyte The divalent vanadium V2+ has reached a certain concentration, put the system discharge program on hold, stop the circulation pump, start the circulation pump and discharge program again after standing for a period of time, and investigate the changes of system parameters.

[0050] Table 4. Table of test parameters for organic matter sealing experiment 3.

[0051] project

v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com