Method for drying medicinal material radix astragali

A medicinal material and drying technology, which is applied in pharmaceutical formulations, drying solid materials, and heating to dry solid materials, etc., can solve the problems of difficult preservation, harm to human health, and time-consuming, and achieve the effect of stable quality and improved quality controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

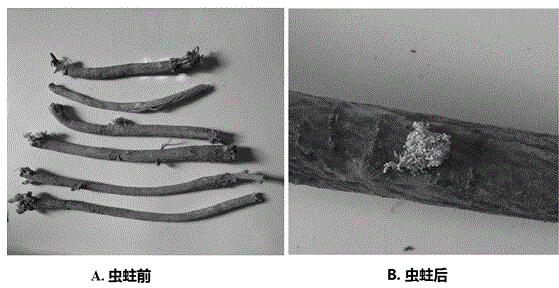

Image

Examples

Embodiment 1

[0014] Example 1 Pretreatment method of Astragalus medicinal materials (removal of impurities, classification)

[0015] After harvesting, the fresh astragalus membranaceus is removed from impurities, residual stems and reed heads, and classified according to three grades with diameters of 3 cm, 2 cm, and 1 cm and below.

Embodiment 2

[0016] Example 2 Traditional drying group The Radix Astragali medicinal material that has been processed by embodiment 1 is tiled respectively according to different grades and is aired and dried in the sun or dried in the shade indoors, and the weight change is always recorded until the moisture content of the medicinal material is below 10%.

Embodiment 3

[0017] Embodiment 3 hot air processing group : The Radix Astragali medicinal material processed by embodiment 1 is respectively placed in an electric heating constant temperature blast drying oven according to different grades, and is dried at 60°C, 70°C, and 80°C respectively until the moisture content is about 46%, then taken out, cooled slightly Straight, continue to bake at the same temperature until the moisture content is below 10%, take it out, let it cool, and it’s ready. According to different drying temperatures, it is divided into hot air 60°C processing group, hot air 70°C processing group and hot air 80°C processing group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com