Arc array of transducer and preparing method

A manufacturing method and arc-shaped array technology, applied in the direction of fluid using vibration, etc., can solve the problems of inability to achieve large-scale and high-power application, large fluctuations in transducer directivity, complex coupling vibration, etc., and achieve good consistency. , The effect of good impedance unimodality and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

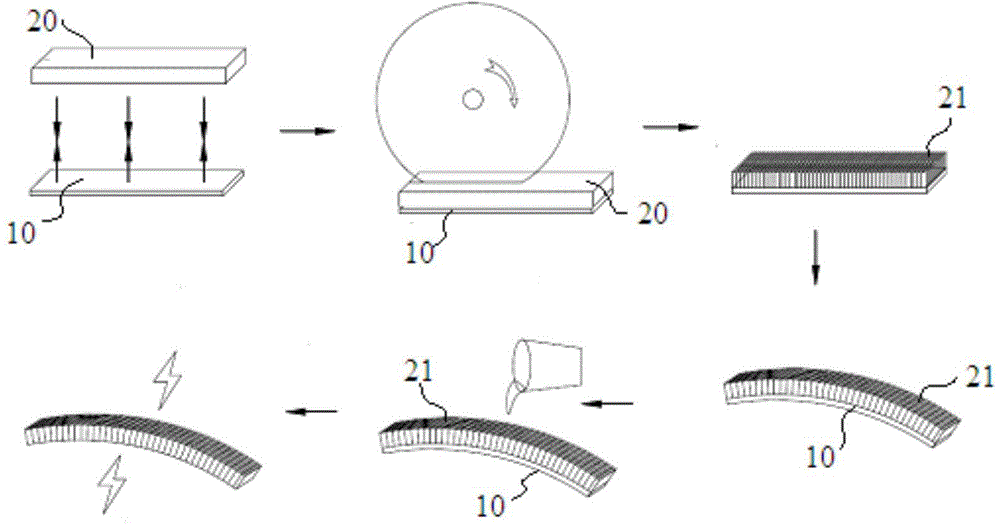

[0022] A method for manufacturing an arc array of transducers, comprising the steps of:

[0023] a) After aligning one end surface of the ceramic material 20 with one end surface of the backing 10, they are tightly bonded, the backing 10 and the ceramic material 20 are bonded by an adhesive, and the backing 10 is a flexible backing .

[0024] b) cutting the ceramic material 20 attached to the backing 10 to obtain a number of uniform and elongated ceramic particles 21 , and the ceramic particles 21 are arranged on the backing 10 in an array.

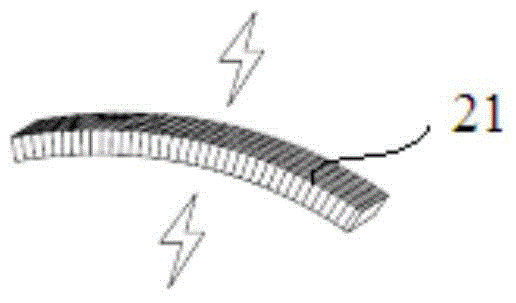

[0025] c) Bending the backing 10 and the array of ceramic particles 21 as a whole in step b), wherein the bending angles of the backing 10 and the array of ceramic particles 21 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com