Automatic waste PET recovery apparatus

An automatic recycling and waste technology, applied in the direction of plastic recycling, recycling technology, garbage collection, etc., can solve the problems of the plastic bottle recycling device not working, the plastic bottle recycling device equipment being damaged, and the waste liquid being unable to be cleaned up in time. Simple, labor-saving, and functional

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

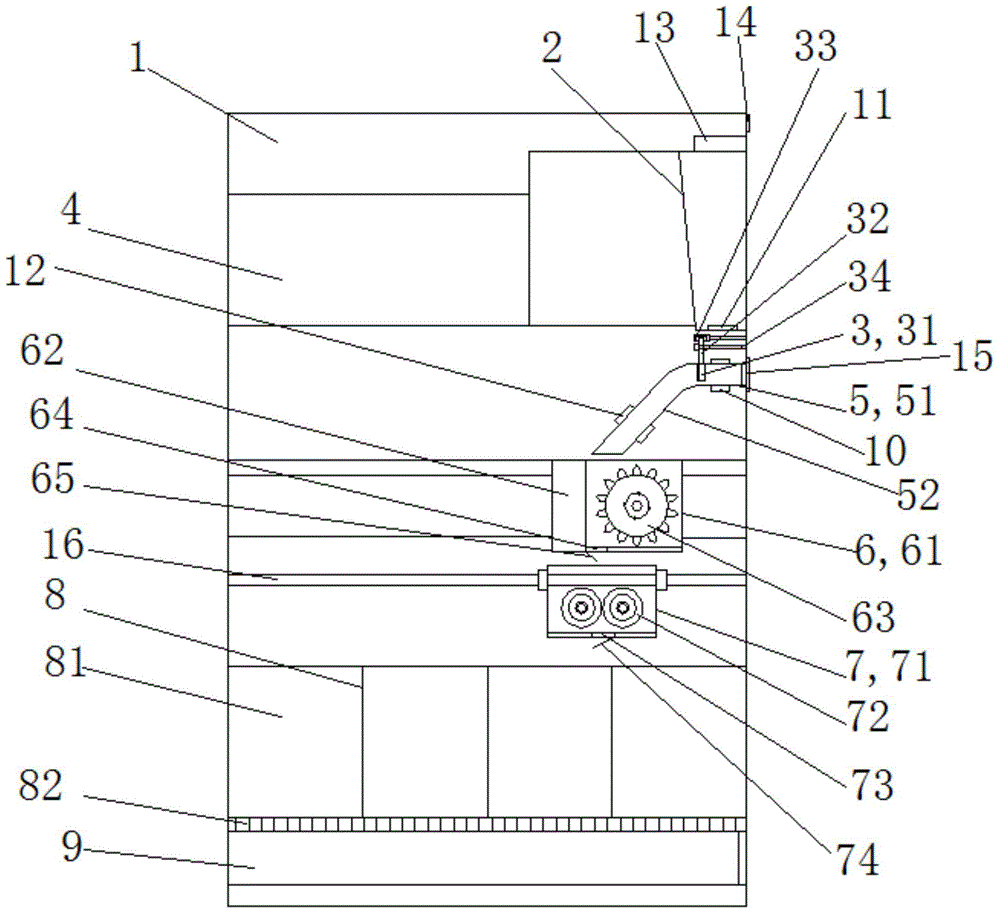

[0018] refer to figure 1 A waste PET automatic recycling device is shown, which includes a housing 1, a display screen 2 arranged on the housing 1, an identification device 11 and a plastic bottle recycling port 15, a controller 4 arranged in the housing 1, a conveying Pipe 5, piercing mechanism 6, flattening mechanism 7, storage bin 8 and liquid collection tank 9, shell 1 is made of plastic or stainless steel, and anti-corrosion coating is sprayed on the outside of the shell, and delivery pipe 5 includes horizontal pipe 51 And the inclined pipe 52, the horizontal pipe 51 is connected at the plastic bottle recovery port, the material detection part 10 is arranged near the inlet end of the horizontal pipe 51, and the movable baffle plate of the automatic switch is arranged on the inner side of the material detection part 10 in the horizontal pipe 51 Mechanism 3, the material color detection part 12 is provided near the outlet end of the inclined pipe 52, the material detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com