Equipment for manufacturing three-dimensional object

A technology of three-dimensional objects and equipment, applied in the field of 3D printing, can solve the problems of no monitoring performance, no application of sintering or melting performance, no way of knowing the temperature change of molten pool, etc., and achieve the effect of improving performance and simple equipment logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, and do not limit the protection scope of the present invention.

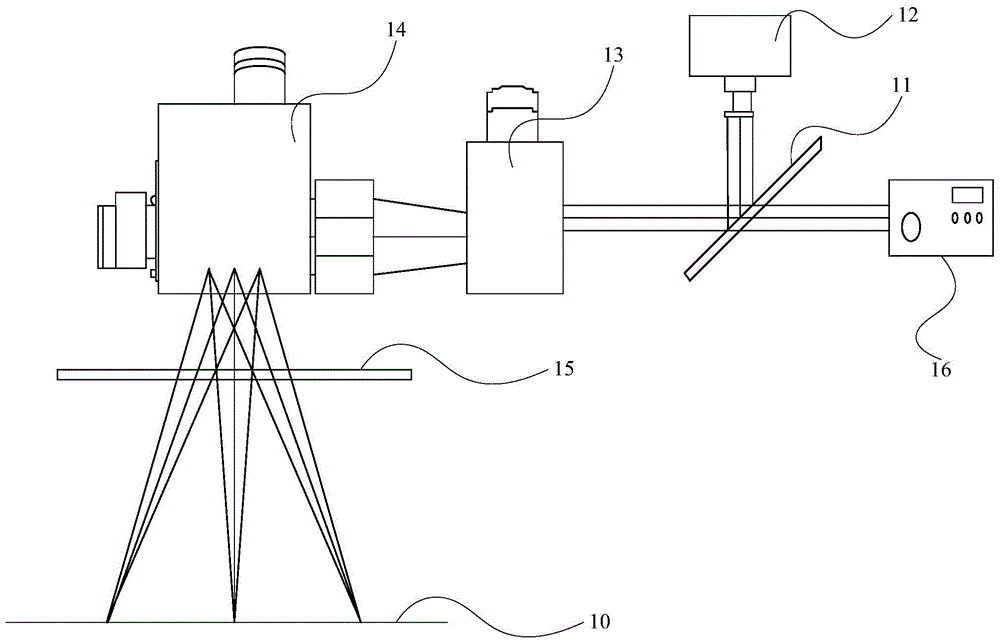

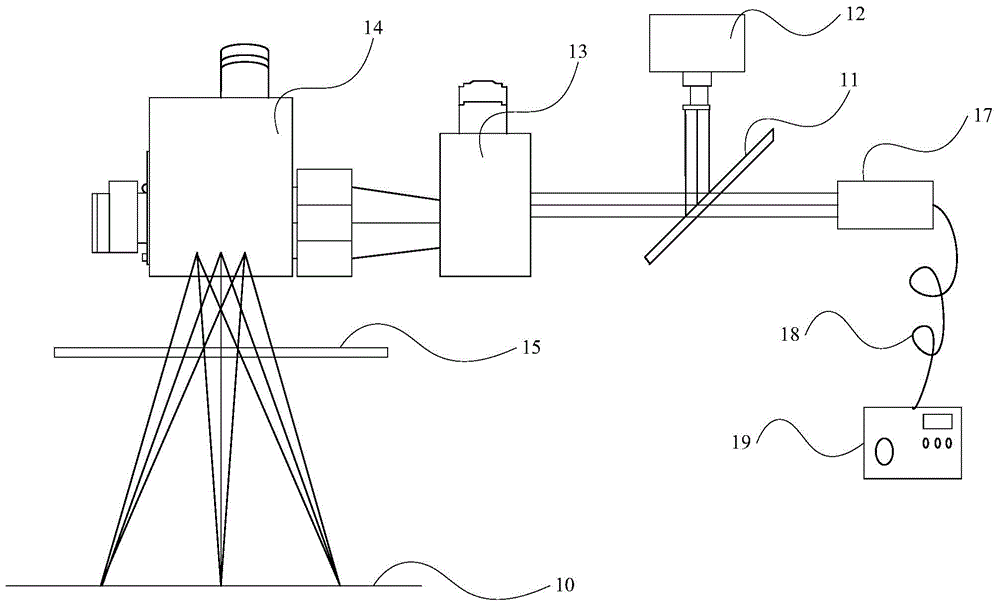

[0012] figure 1 A schematic structural diagram of a device for manufacturing a three-dimensional object in an embodiment of the present invention is shown in FIG. Such as figure 1 As shown, the equipment in this embodiment includes: a light splitting unit 11, an image monitoring device 12, a dynamic focus module 13, a galvanometer system 14, and a window mirror 15. The light splitting unit 11, the image monitoring device 12, and the dynamic focus module 13 , The galvanometer system 14 and the window mirror 15 pass between figure 1 Show the optical path to establish th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com