Method used for preparing ZnO/SiO2 nano composite material

A technology of nano-composite materials and mixed solution, applied in the field of preparing ZnO/SiO2 nano-composite materials, can solve the problems of long time, high cost, complicated steps, etc., and achieve the effect of reducing the amount of use and simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of zinc bromoacetate: put 1g ZnO and 3.415g bromoacetic acid into a single-necked round-bottomed flask filled with 100ml of high-purity water in turn, react at 60°C for 1 hour, filter to obtain a clear solution, and evaporate the solvent with a rotary evaporator A white solid was obtained.

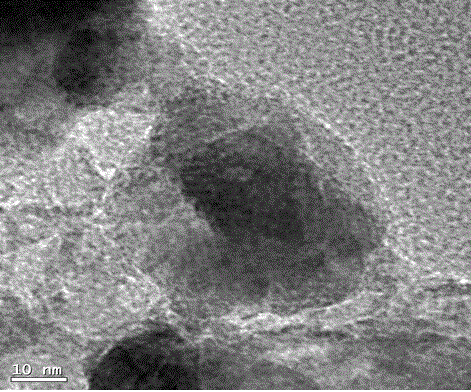

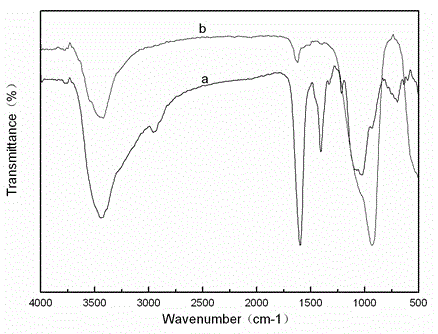

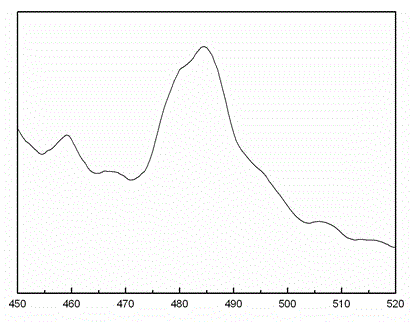

[0026] 2. ZnO / SiO 2 Preparation of fluorescent nanocomposites: Dissolve 1.4g of zinc bromoacetate in a mixed solution of 60ml of water and ethanol (volume ratio of water and ethanol=1:1). Dissolve 2.17ml of 3-aminopropyltriethoxysilane and 0.17ml of tetraethyl orthosilicate in 40ml of absolute ethanol and add it dropwise to the solution of zinc bromoacetate to control the amount of the three substances The ratio is zinc bromoacetate:APTES:TEOS=1:2:0.15, magnetically stirred at normal temperature and pressure for 6h, centrifuged at a rate of 8500r / min, and a white powder was obtained after removing the supernatant. Next, it was repeatedly washed with absolute ethanol...

Embodiment 2

[0030] One, the preparation of zinc 3-bromopropionate: 1g ZnO and 4.2g 3-bromopropionate are added successively in a single-necked round-bottomed flask with 100ml high-purity water, and the resulting solution is filtered after reacting in a water bath at 60°C for 1.5h, and the obtained The clear solution was evaporated completely under the rotary evaporator to obtain a white powder.

[0031] 2. ZnO / SiO 2 For the preparation of fluorescent nanocomposites, 1.5 g of zinc 3-bromopropionate was dissolved in a mixture of water and ethanol with a volume ratio of 1:1. Add 2.1ml of APETS and 0.2ml of TEOS mixture into 40ml of absolute ethanol and add this dropwise to the previously obtained zinc 3-bromopropionate solution, controlling the ratio of the three substances to zinc bromoacetate:APTES:TEOS= 1:2:0.15. React at normal temperature and pressure for 6 hours, centrifuge at a speed of 8000 r / min, and wash with ethanol 2-3 times. Dry in a vacuum oven at room temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com