A kind of functional vinegar rich in ferulic acid and production method thereof

A production method, the technology of ferulic acid, applied in the field of food brewing, can solve the problem of undiscovered ferulic acid in vinegar, etc., and achieve the effect of increasing the content of ferulic acid and unique taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

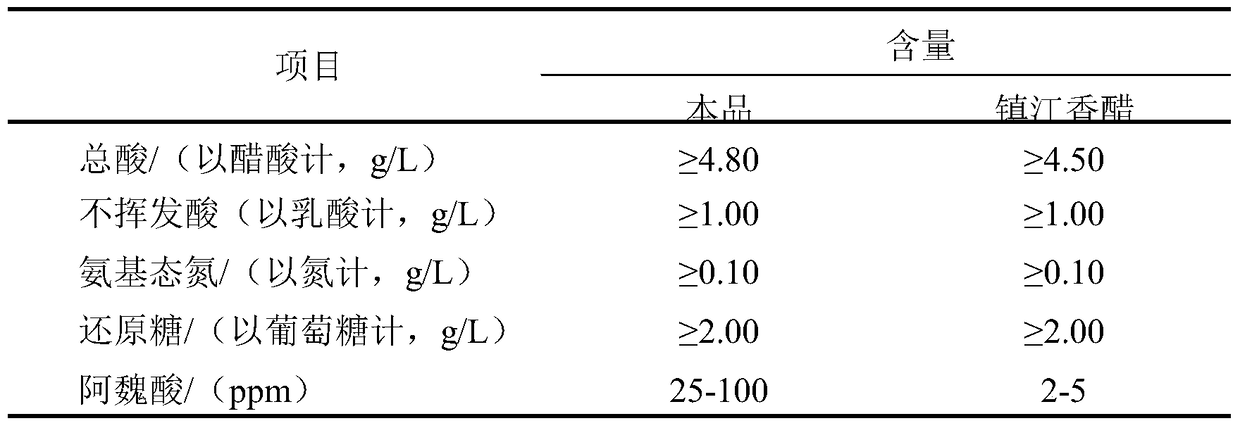

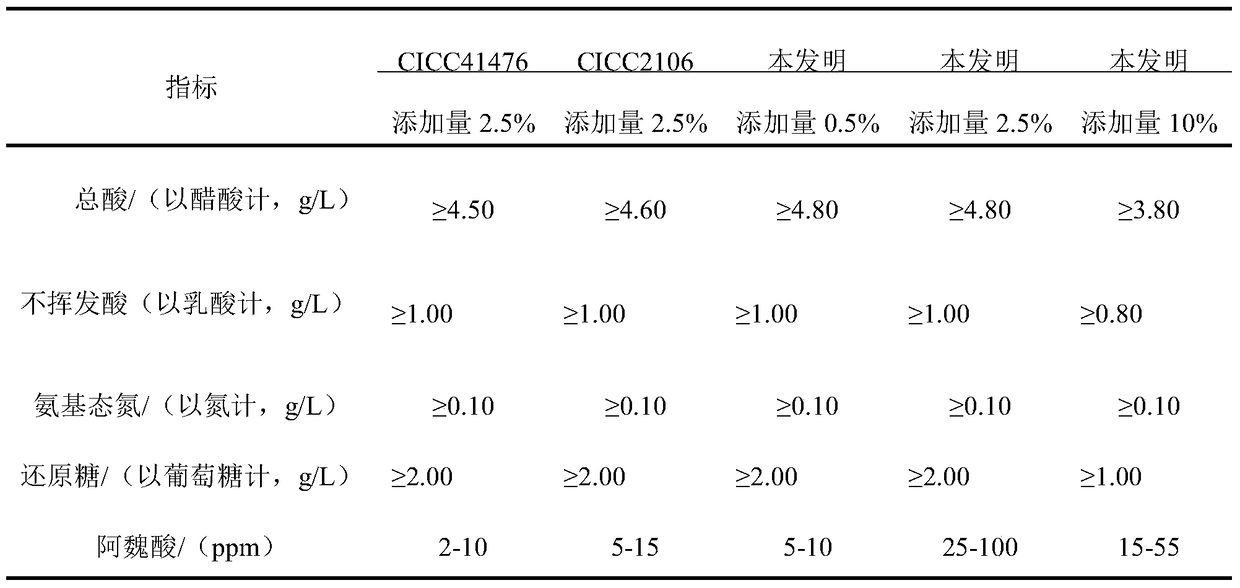

[0021] Embodiment 1 is rich in the preparation of ferulic acid vinegar

[0022] (1) The raw material glutinous rice is made into glutinous rice through steps such as soaking rice, steaming rice, and pouring rice.

[0023] (2) Alcoholic fermentation: evenly mix 0.4% wine medicine in the glutinous rice, and after saccharification at 18°C for 56 hours, add 30% water and 5.5% Zhenjiang balsamic vinegar Daqu, and keep warm at 30°C for 5 days. That is to get the mature fermented grains.

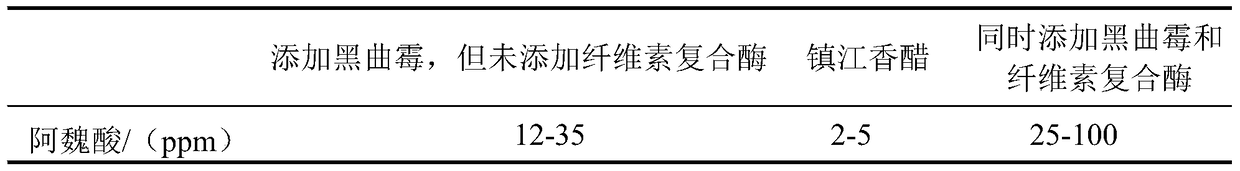

[0024] (3) Acetic acid fermentation: mix the wine grains with 1.3 times the bran of the raw material mass evenly, insert the Aspergillus niger suspension accounting for 2.1% of the raw material weight at the same time, add the cellulose compound enzyme accounting for 2% of the raw material mass, and obtain the wine bran mixture. Stir in bran with 5% mass of raw material, inoculate 1% vinegar unstrained spirits at the same time, ferment at 30°C, and ferment for 15 days.

[0025] (4) The vinegar...

Embodiment 2

[0026] Embodiment 2 is rich in the preparation of ferulic acid vinegar

[0027] (1) The raw material glutinous rice is made into glutinous rice through steps such as soaking rice, steaming rice, and pouring rice.

[0028] (2) Alcoholic fermentation: evenly mix 0.5% of the raw material wine medicine into the glutinous rice, after saccharifying at 18°C for 48 hours, add 30% of the raw material by weight of water, 5.5% of Zhenjiang vinegar Daqu, and keep warm at 30°C for 5 days. That is to get the mature fermented grains.

[0029] (3) Acetic acid fermentation: mix the wine grains with 1.5 times the bran of the raw material quality evenly, insert the Aspergillus niger suspension accounting for 5% of the raw material weight at the same time, add the cellulose compound enzyme accounting for 5% of the raw material quality, and obtain the wine bran mixture. Stir in bran with 5% mass of raw material, inoculate with 1.5% vinegar fermented grains at the same time, ferment at 30°C, an...

Embodiment 3

[0031] Example 3 Preparation of Vinegar Rich in Ferulic Acid

[0032] (1) Glutinous rice is made by soaking rice, steaming rice, pouring rice and other processes.

[0033] (2) Alcoholic fermentation: evenly mix 0.45% of the raw material weight wine medicine into the glutinous rice, after saccharifying at 18°C for 52 hours, add 30% of the raw material weight of water, 5.5% of Zhenjiang vinegar Daqu, and keep warm for 5 days at 30°C. That is to get the mature fermented grains.

[0034] (3) Acetic acid fermentation: mix the wine grains with 1.4 times the bran of raw material quality evenly, insert the Aspergillus niger suspension that accounts for 3% of raw material weight at the same time, add the cellulose compound enzyme that accounts for 2.5% of raw material quality, get wine bran mixture. Stir in bran with 5% raw material quality, inoculate 2% vinegar unstrained spirits at the same time, ferment at 30°C, and ferment for 15 days.

[0035] (4) The vinegar fermented grains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com