Durable super-hydrophobic and super-oleophobic textile finishing agent and finishing method thereof

A super-hydrophobic and super-oleophobic, textile finishing technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of adding toxic substances to the finishing agent, high cost, and weak adhesion between the finishing agent coating and the substrate. , to achieve the effect of simple and easy method, overcoming high cost and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

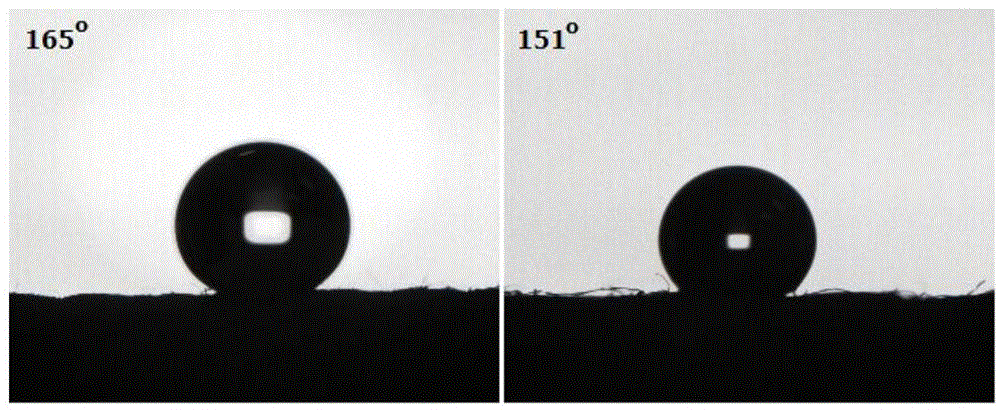

[0024] Embodiment 1: durable superhydrophobic superoleophobic textile finishing agent A

[0025] Slowly add 5g of tetraethoxysilane dropwise into the mixed solution of 300mL ethanol and 30mL ammonia water, and react for 24h. The supernatant was removed by centrifugation and dried. Wash the silica spheres with ethanol, repeat centrifugation, drying and washing 5 times, and dry overnight at 80°C. 1g of silicon spheres, 5g of fluorine-containing polyether with a molecular weight of 500, 2g of TDI, and 0.1g of dibutyltin dilaurate were dispersed in 100mL of acetone to obtain durable superhydrophobic and superoleophobic textile finishing agent A. Soak 1g of cotton cloth in the above-mentioned durable superhydrophobic and superoleophobic textile finishing agent A for 5 hours, put the soaked cotton fabric in an oven for pre-baking at 80°C for 30min, and bake at 120°C for 24h to obtain superhydrophobic and superoleophobic textile A.

Embodiment 2

[0026] Embodiment 2: durable superhydrophobic superoleophobic textile finishing agent B

[0027] Slowly add 5 g of tetraethoxysilane silane dropwise into a mixed solution of 300 mL of ethanol and 30 mL of ammonia water, and react for 24 hours. The supernatant was removed by centrifugation and dried. Wash the silica spheres with ethanol, repeat centrifugation, drying and washing 5 times, and dry overnight at 80°C. 1g of silicon spheres, 5g of fluorine-containing polyether with a molecular weight of 1000, 2g of TDI, and 0.1g of dibutyltin dilaurate were dispersed in 100mL of acetone to obtain durable superhydrophobic and superoleophobic textile finishing agent B. Soak 1g of cotton cloth in the above-mentioned durable superhydrophobic and superoleophobic textile finishing agent B for 5 hours, put the soaked cotton fabric in an oven for pre-baking at 80°C for 30min, and bake at 120°C for 24h to obtain superhydrophobic and superoleophobic textile B.

Embodiment 3

[0028] Embodiment 3: durable superhydrophobic superoleophobic textile finishing agent C

[0029] Slowly add 5 g of tetraethoxysilane silane dropwise into a mixed solution of 300 mL of ethanol and 30 mL of ammonia water, and react for 24 hours. The supernatant was removed by centrifugation and dried. Wash the silica spheres with ethanol, repeat centrifugation, drying and washing 5 times, and dry overnight at 80°C. 1g of silicon spheres, 10g of fluorine-containing polyether with a molecular weight of 2000, 2g of TDI, and 0.1g of dibutyltin dilaurate were dispersed in 100mL of acetone to obtain durable superhydrophobic and superoleophobic textile finishing agent C. Soak 1g of cotton cloth in the above-mentioned durable superhydrophobic and superoleophobic textile finishing agent C for 5 hours, put the soaked cotton fabric in an oven for pre-baking at 80°C for 30min, and bake at 120°C for 24h to obtain superhydrophobic and superoleophobic textile C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com