Prefabricated pump station

A technology for pumping stations and control cabinets, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of complex structure of prefabricated pumping stations and generation of harmful gases, etc., to reduce the scope of investigation, reduce the generation of odor, and reduce the diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

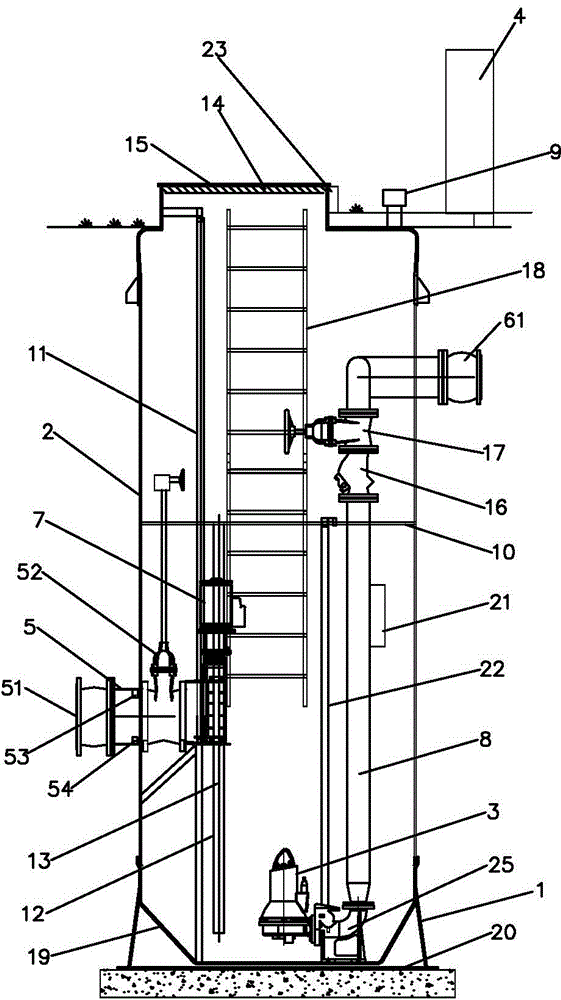

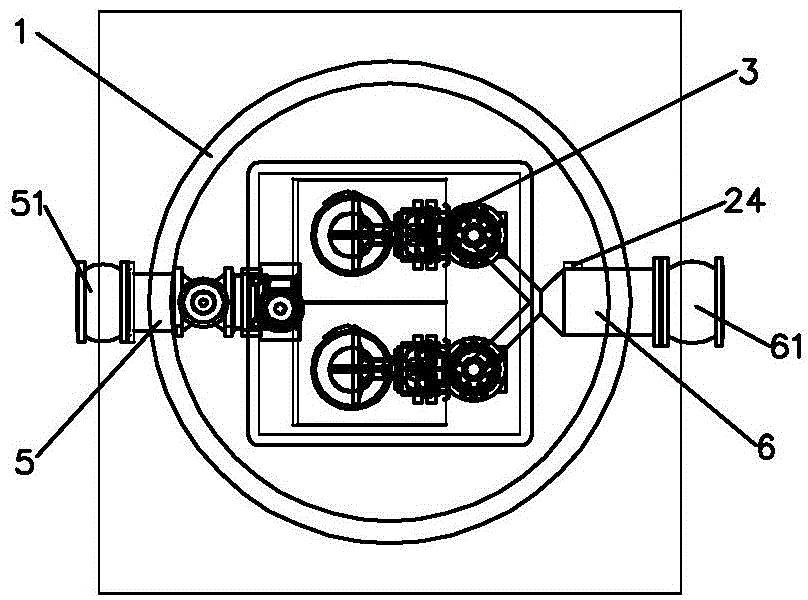

[0026] as attached figure 1 to attach figure 2 As shown, a prefabricated pumping station of the present invention includes a base 1, a cylinder 2 disposed on the base 1, a submersible sewage pump 3 disposed at the inner bottom of the cylinder 2, and a control cabinet 4 for controlling the operation of the submersible sewage pump 3 A water inlet pipe 5 is provided on one side of the cylinder body 2, and a water outlet pipe 6 is provided on the other side. A pulverized grille 7 is provided in the cylinder body 2. The flow cover is connected, the water outlet of the submersible sewage pump 3 is connected with the water outlet pipe 6 through the pressure pipeline 8, the control cabinet 4 is respectively connected with the pulverized grille 7 and the submersible sewage pump 3, and the water inlet pipe 5 is equipped with a knife gate valve 52, a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com