Conical sealing type hydraulic large-flow high-speed digital valve

A technology of conical surface sealing and large flow, which is applied in the field of solenoid valves, can solve the problems of lax closing, inability to open, and low electromagnetic efficiency, and achieve the effects of improved sealing effect, compact overall structure, and high electromagnetic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

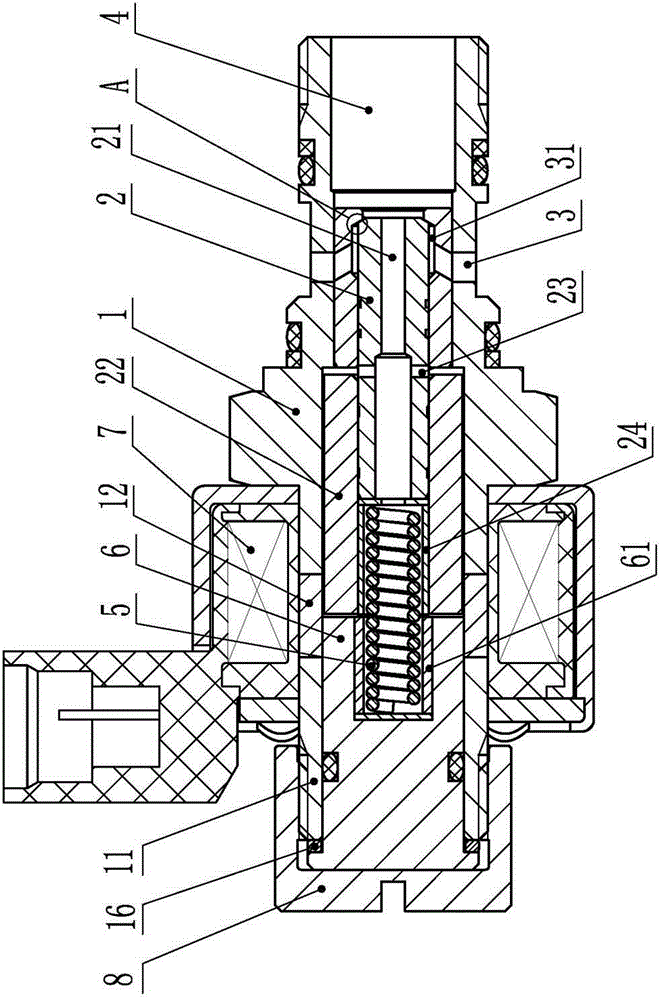

[0014] like figure 1 As shown, the cone-sealed hydraulic high-flow high-speed digital valve includes a valve body and a valve core 2 slidingly installed in the valve body. An armature 22, a fixed armature 6 is installed in the valve body behind the moving armature 22, a spring 5 is arranged between the fixed armature 6 and the spool 2, and a through hole 21 that runs through the front and back is provided at the center of the spool 2. The valve body is provided with a liquid inlet 3 and a liquid outlet 4 , the liquid inlet 3 is arranged around the valve core 2 , and the liquid outlet 4 is located at one end of the valve body and on the axis of the valve core 2 . When the valve is opened, the liquid enters the inner cavity of the valve body through the liquid inlet 3, and then is discharged through the liquid outlet 4. The through hole 21 can introduce the liquid at the front end of the valve core 2 into the cavity at the rear end of the valve core 2, so that the valve core 2 ...

Embodiment 2

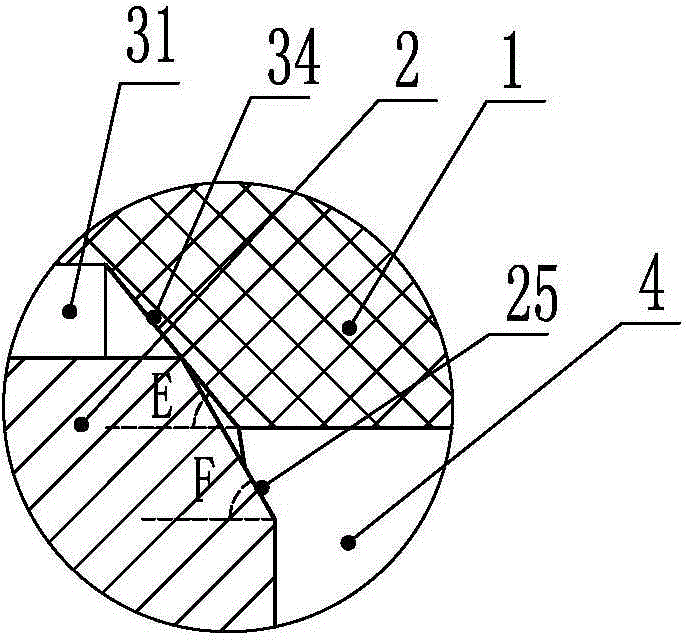

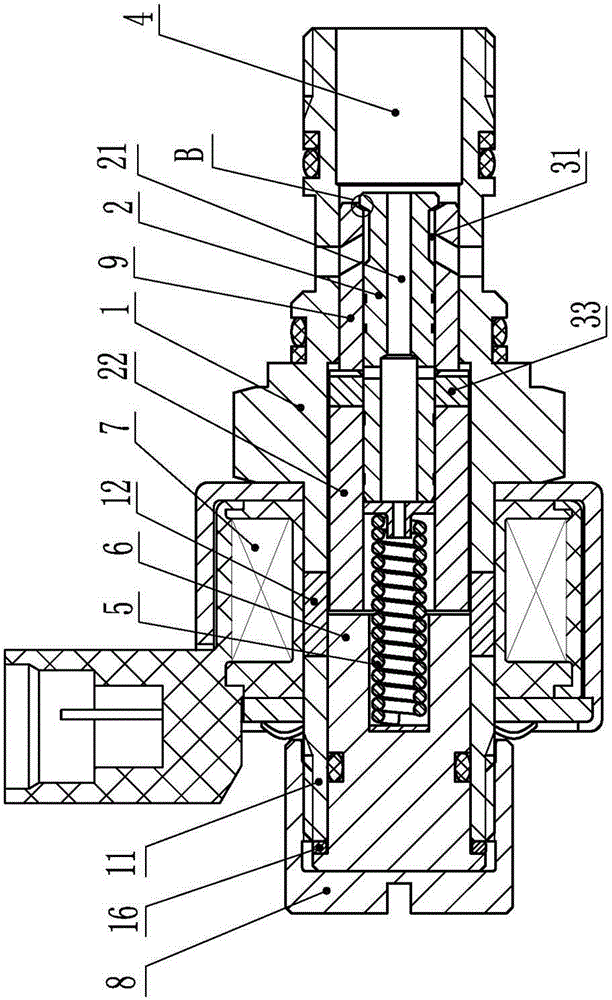

[0021] like image 3 As shown, the inner cavity of the front valve body 1 is provided with a boss 9 surrounding the valve core 2, and the front end of the boss 9 is provided with an inner tapered surface 34 in the shape of an inner chamfer, and the valve core 2 is provided with a There is an annular buffer tank 31 communicating with the liquid inlet 3 . like Figure 4 As shown, the front end of the buffer tank 31 is provided with an outer tapered surface 25 matching the inner tapered surface 34 , and the inclination angle G of the inner tapered surface 34 is greater than the inclination angle H of the outer tapered surface 25 . This embodiment is a normally open valve. When the valve core 2 moves to the rear end and the valve is closed, the outer cone surface 25 matches the inner cone surface 34 to form a seal. Since the inclination angles of the two cone surfaces are not equal, the seal here is determined by the inner cone surface. The innermost corner of the conical surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com